LG Energy Solution Michigan has a department dedicated to creating the ideal environment for battery assembly in North America. Let’s get started on the third episode of the Relay Virtual Tour, led by local employees from the Michigan office!

*Check out [Relay Virtual Tour] Introducing Our LG Energy Solution Michigan – Part 1

*Check out [Relay Virtual Tour] Introducing Our LG Energy Solution Michigan – Part 2

(Elaine Powell, Coordinator Manager)

Hello, my name is Elaine Powell, and I am the third runner in the LG Energy Solution Michigan Relay Virtual Tour. I work as a coordinator manager in the assembly department. Today, I’ll take you on a tour of my workday!

Coordinator at the Michigan office, optimizing the battery assembly production environment

First, let’s meet our team of coordinators in the assembly department and see what they’re up to.

[Quick Interview] What are your responsibilities as coordinators at the Michigan office?

(Elaine Powell, Coordinator Manager)

Let’s check out the team in charge of training and production coordination. What are you working on?

(Sue Eggerding, Training Coordinator)

Hello, my name is Sue Eggerding, and I work as a training coordinator. I am working on training materials about alert situations. This material will be used in our weekly employee training session.

(Mya Sybounma, Production Coordinator)

My name is Mya Sybounma, and I work as a production coordinator. I am working on a digital on-the-job-training (OJT) book that is useful on-site. The QR codes on the monitor next to me are for digital OJT books.

(Elaine Powell, Coordinator Manager)

Now, let’s meet the operator training team. Tell us a little bit about what you do.

(Bob Syring, Assembly Coordinator)

Hello, my name is Bob Syring. I am currently working on the operation manual for machine line 1.

(Elaine Powell, Coordinator Manager)

Finally, let’s see what the simulator team is up to. What are you working on?

(Vitoria Peters, Training Coordinator)

My name is Vitoria Peters. I’m currently working on a simulator. We use the simulator for building technology and training for practitioners.

A coordinator’s job includes monitoring the site conditions

(Elaine Powell, Coordinator Manager)

Now that we have met the practitioners from each team, let’s go to the dry room* to make sure everything is running smoothly on site.

* Dry room: A room where the air’s moisture can be controlled to improve battery quality and yield.

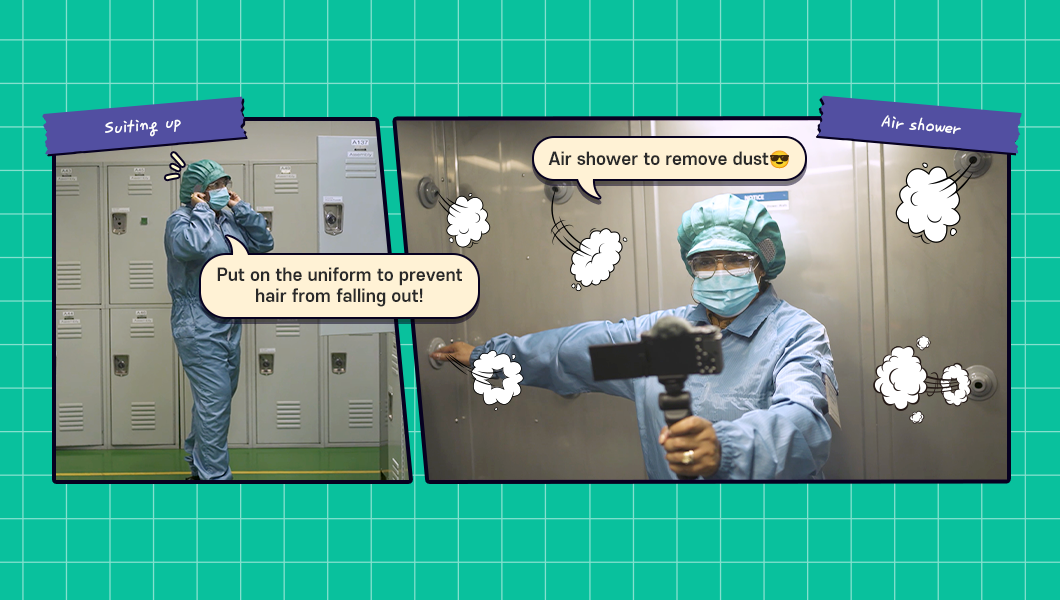

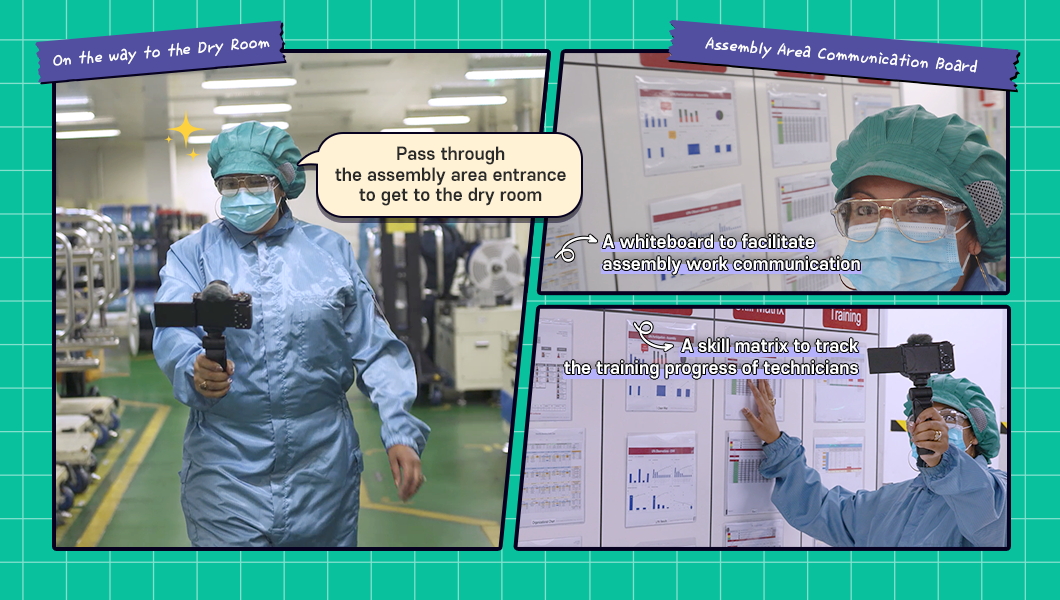

Before entering the dry room, you must first change into your work outfit. After you’ve put on your coverall suit, safety glasses, hair net, and mask, you’ll be ready to enter the room. After you walk through an air shower and remove dust from your clothes and shoes, you can go inside the dry room.

There is an entrance to the assembly area on the way to the dry room. A whiteboard serves as a communication channel, showing on-site work progression, the workforce roster and organization, contextual communication, and production plans. In addition, the Skill Matrix* chart shows the training progress of technicians.

*Skill Matrix: A chart illustrating the advancement of technicians in their training

In this episode, we saw how the coordinators at LG Energy Solution Michigan work. In the fourth series of the Relay Virtual Tour, we will meet employees from other parts of the Michigan office. Stay tuned for more Relay Virtual Tour episodes with LG Energy Solution employees!

https://youtu.be/sCGze5WZsJw