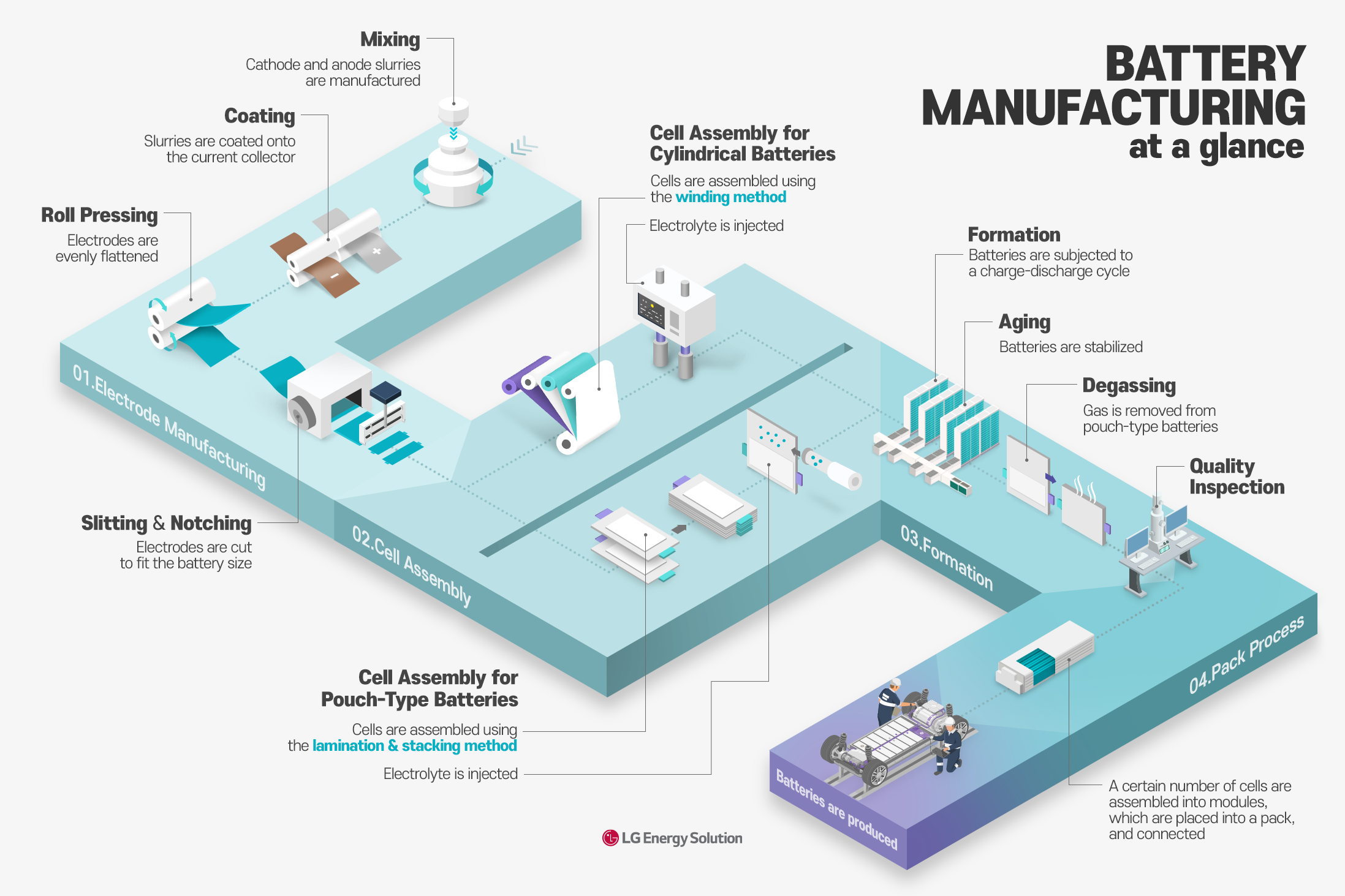

The manufacturing process of lithium-ion batteries consists largely of 4 big steps of electrode manufacturing, cell assembly, formation and pack production, in that order. Each step employs highly advanced technologies. Here is an image that shows how batteries are produced at a glance.

▶STEP 1. Electrode manufacturing – making the cathode and anode of a battery

① Mixing : Basic battery materials, such as cathode and anode active materials and solvents, are mixed to make a slurry, an intermediate product. At this stage, binders are added to enhance adhesion between active material particles, while conductive additives are incorporated to facilitate electron transport between them.

* View more about mixing

② Coating : The completed cathode and anode slurries are thinly coated onto aluminum and copper foils respectively. In this process, binders are evenly dispersed onto electrodes for higher performance and longer life of batteries. LG Energy Solution became the first in the industry to introduce the Double Layer Slot Die Coating (DLD) method of coating different electrode slurries onto the current collector at the same time.

* View more about coating

③ Roll Pressing : When the coating is done, electrodes go through two big rolls and get evenly flattened. The electrode surface bonds to active materials better, allowing lithium ions to travel more easily. As a result, the output and performance of the batteries improve.

* View more about roll pressing

④ Slitting and Notching : The flattened electrodes are cut into required sizes to fit for the battery. They are slit vertically in the slitting process and cut horizontally to get a V-shaped notch as well as cathode and anode tabs in the notching process.

* View more about slitting and notching

▶STEP 2. Cell assembly – forming the battery shape (pouch/ cylindrical batteries)

In the cell assembly process, batteries take the shapes as we know them. The order of manufacturing process differs depending on the shape (cylindrical, pouch, and prismatic types) and each battery maker employs different technology.

Pouch-type battery: First, a mono-cell is manufactured as the basic unit for battery production. Then, a cell stack is assembled using the lamination & stacking method. Next, a pouch film is compressed to form a pouch case, consisting of an electrode pocket and a gas pocket. The cell stack is then placed into the electrode pocket and sealed. Finally, electrolyte is injected through the gas pocket into the pores of the electrode pocket, and the injection port is sealed.

* View more about cell assembly of pouch-type battery (Ep.1)

* View more about cell assembly of pouch-type battery (Ep.2)

Cylindrical battery : Cathode, anode, and separator are rolled up using the “winding” method. An aluminum tab is attached to the uncoated part of cathode and a copper tab on that of anode of the resulting “jelly roll.” Then, it is fixed in the cylindrical battery can. Electrolyte is injected. Lastly, after an insulated tube is put on the completed battery to separate the cathode and anode and prevent short circuits, then it has the shape of a cylindrical battery.

* View more about cell assembly of cylindrical battery

▶STEP 3. Formation – activating a battery with electrical energy and stabilizing it

The next step is formation where batteries are activated with electric energy and their safety is checked. This process consists of repeated aging, charging, and discharging. First, the battery is put at room temperature so that electrolyte can permeate into the cathode and anode, which is called “aging.” When the electrolyte soaks into the inside of the battery and ions move smoothly between the cathode and anode, the battery is charged to a certain level.

(* The formation process differs by manufacturers.)

In pouch-type batteries, gas can accumulate inside the cell due to repeated aging and charge-discharge cycles. The degassing method removes gas generated from electrolyte side reactions during the initial charging stage. After degassing, the battery undergoes additional aging and charge-discharge cycles to assess its performance, including capacity and resistance. Following a designated storage period, an OCV (Open-Circuit Voltage) measurement is conducted to identify low-voltage cells. Finally, defective batteries are detected and removed in the final EOL (End-of-Line) process.

* View more about formation

▶STEP 4. Pack process – forming a module to fit for the models

The pack process involves modularizing manufactured battery cells and assembling them into a pack. When integrating batteries into EVs, they must be modularized according to the vehicle model. First, multiple battery cells are arranged in a Cell-to-Cell configuration and secured within a module case. The cells are then interconnected, and the top cover is assembled to complete the module. Finally, the completed modules are placed into the battery pack and connected in a Module-to-Module configuration, finalizing the pack assembly.

* View more about pack process

We have taken a look at battery manufacturing at a glance. Each step contains more detailed procedures. Next time, we will explore key processes of each step and specific technologies of the step with an infographic.