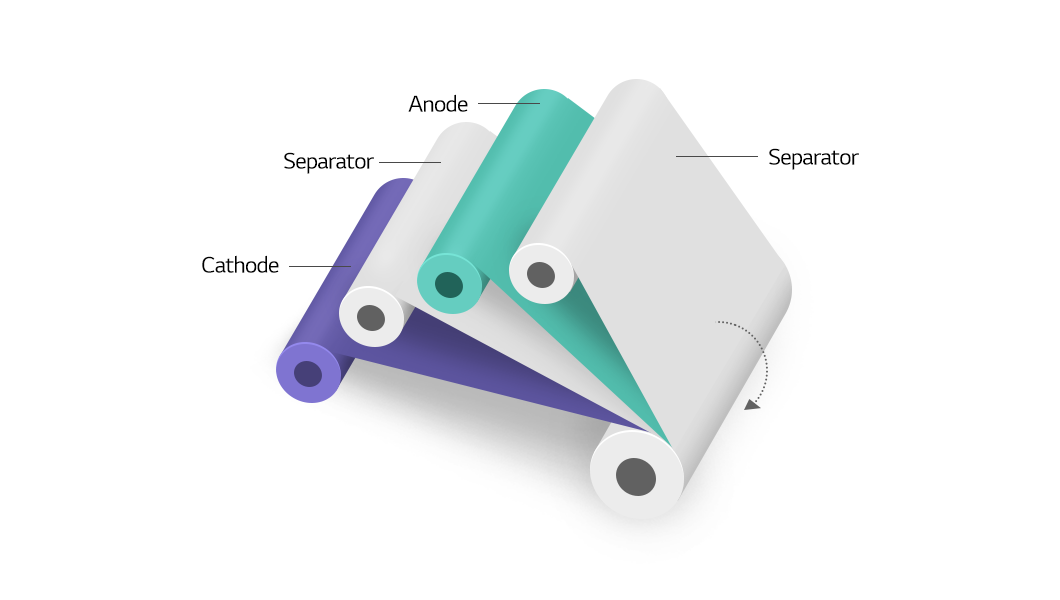

Unlike the pouch battery we explored last time, the cathode and anode produced through the electrode manufacturing process need to be rolled up to make a cylindrical battery.

A machine called winder is used for this job.

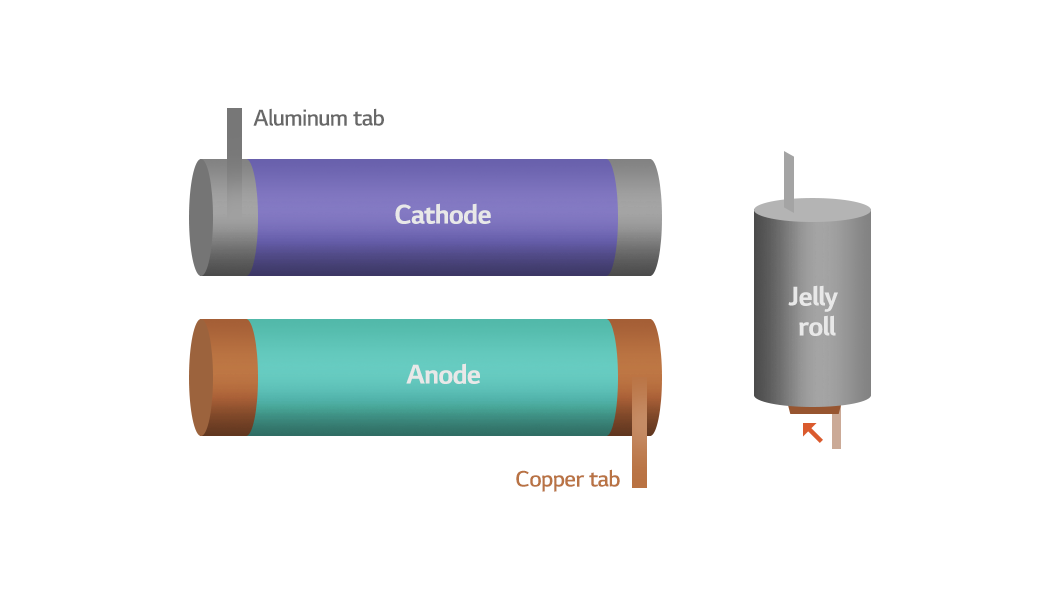

First, a cathode roll, an anode roll, and two separator rolls are attached to the winder. Then they are wound around a mandrel and cut to proper length to form a jelly roll.

Fixing Jelly Roll

Next, the jelly roll with a copper tab and an aluminum tab on the uncoated parts of anode and cathode respectively is put in the cylindrical battery can. The anode tab is bent into an L shape and the cathode tab into a hook shape. The former is welded onto the bottom of the can and the latter onto the top of it. After that, the jelly roll in the can is fixed through beading.

*Beading: Resistance welding. Also called spot welding, as the welding beads look like spots.

Injection of Electrolyte

The next move is to inject electrolyte. After creating a vacuum state in the inside of the can, the required amount of electrolyte is injected into it through a nozzle. Then, the electrolyte is let to fill the pores of the electrode by pressing the can. When this process is over, the top cap is crimped.

*Crimping: Sealing the cap by compressing it.

Completion of Cylindrical Battery

An insulated tube is put on the completed battery to separate the cathode and anode and prevent short circuits. The shape of a cylindrical battery as we know it is formed in this stage.

We have covered the manufacturing processes of cylindrical batteries following pouch batteries. Now that they have a shape, they need electrical properties. Next time, we will move on to formation, the third step of battery manufacturing!