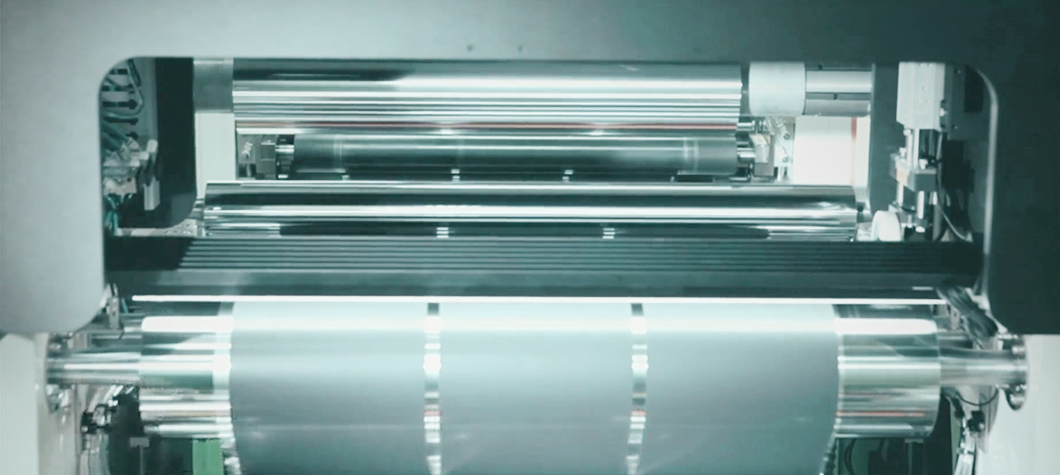

After the mixing process where the cathode and anode materials are mixed, the next step of battery electrode manufacturing is coating. In this process, the cathode and anode slurries, intermediate goods produced in the mixing process, are applied onto aluminum and copper foils respectively.

What is Coating Process?

It is to disperse binders contained in the intermediate goods evenly onto electrodes for uniform performance and longer life of the battery. Taking up 18% of the entire process, the coating is highly important because most of battery design parameters are determined in this step. Techniques for even coating and controlling the “roll-to-roll” machine are necessary to avoid damaging the aluminum and copper current collectors.

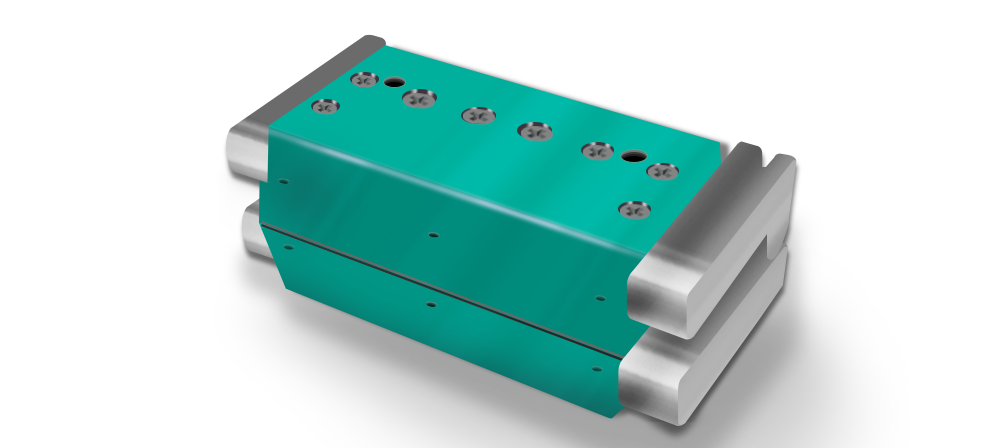

Slot Die

For lithium-ion batteries, slot die method that allows a quick coating is commonly used. This technique lets the slurries go through the slot die, that is the head of coating machine and that acts like a mold, applying it in a uniform pattern and thickness. In this method, the electrode is normally conveyed horizontally, and coatings cannot be applied onto both sides at the same time. So, when one side is coated, it has to be dried in at least a 100°C oven before the other side is coated.

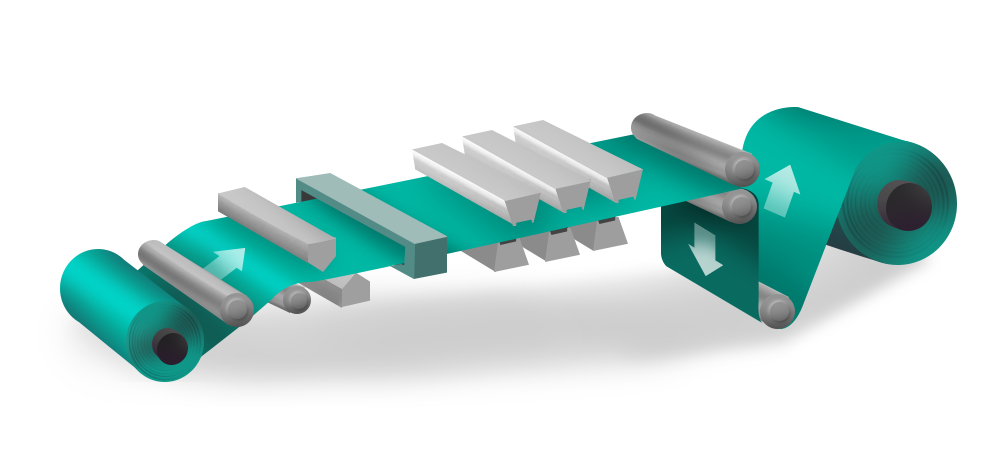

Double Layer Slot Die Coating (DLD)

LG Energy Solution became the first in the industry to introduce the Double Layer Slot Die Coating (DLD) method that allows coating electrode slurries onto the current collector at the same time. Compared to the single-layer method, DLD is better at dispersing binders evenly onto electrodes, raising efficiency of binders. Accordingly, it contributes to enhancing battery charging speed, performance and productivity. The technique was already adopted and is being used for producing car batteries and small batteries.

When coating is completed, now the slurries are compressed into the desired thickness. Next time, we will examine the third step of electrode manufacturing, “roll pressing.”