Although smartphones, a must-have in today’s world, vary in shape and performance, the USB charging port has been standardized, and the same type is used all over the world. Therefore, even if you export a smartphone, there are no problems finding the right charger in the importing country, while safety is also secured thanks to standardized specifications.

Likewise, codes and standards are applied to designing and manufacturing batteries, including the battery energy storage system (BESS). The details were confirmed at the ‘LG Tech Conference 2024’ held at LG Sciencepark in Magok, Gangseo-gu, Seoul on April 4. Let’s take a closer look at the details of the presentation by Jinman Kim of Power Grid System Development Team 2.

BESS (Battery Energy Storage System), which stores energy using batteries

Electrical energy is ‘instantaneous’ energy that must be consumed immediately once it is produced. If there is no separate storage device, the generated electrical energy disappears. However, if you take a conservative approach, considering that surplus electrical energy will disappear, power outages may occur due to a power shortage. Therefore, a way to manage energy more efficiently was needed. As a solution to this problem, LG Energy Solution focused on batteries and energy storage systems (ESS).

Existing nuclear power and thermal power are base generators* where the amount of power generation can be controlled, while new and renewable energy generates an irregular amount of power due to weather or other factors. This may cause the quality of electricity to deteriorate, failing to meet the frequency or phase specifications, which may adversely affect home appliances or equipment.

* Base generator: A generator that guarantees a certain level of operation at all times

In this way, ESS is needed to ensure a stable power supply from renewable energy and to adjust frequency fluctuations*. There are three major roles of ESS: △ Renewable Integration, △ Peak Shifting (Intensive use of stored power during peak hours), and △ Frequency Regulation.

*Frequency fluctuations are variations in the rotational speed of a synchronous generator.

ESS can be categorized into power grid ESS, industrial and residential ESS, and UPS (Uninterruptible Power Supply). Power grid ESS is used for transmission and distribution applied to power plants. Residential ESS systems have been well distributed in Europe and North America and LG Energy Solution is providing ESS products for residential use in line with the trend. In addition, to prevent power outages in servers and communication base stations, batteries are used for UPS as an energy source. These are viewed as a field of BESS.

ESS using lithium ions

Looking at the structure of ESS, it basically consists of battery cells and the battery management system (BMS) that plays a monitoring role, and these are packaged to form a pack. Next, multiple packs are stacked to complete one battery system (container), which is then supplied to the power grid. Recently, ESS farms are often built on separate, large sites. LG Energy Solution is developing and manufacturing battery system solutions to keep up with the trend.

In fact, ESS does not necessarily require the use of batteries to play its role. A similar role can be played by compressed air or pumped hydroelectric generation that utilizes mechanical energy. However, the most preferred BESS system in the current ESS market is a system using lithium-ion batteries. Then, why lithium-ion batteries among the many batteries? This is because ESS is not used only for specific outputs or specific spaces, meaning it must have high versatility to be used for high output or high energy. In addition, the needs of customers in the market, such as management and maintenance, must be met. In this respect, other batteries incur higher incidental costs than lithium-ion batteries.

What is the outlook for the future ESS market?

LG Energy Solution is mainly targeting the North American ESS market. In the United States, the power infrastructure was built a long time ago, leading to power outages due to aging infrastructure. However, because the continent is so large, it is not easy to replace all transmission and distribution lines. Therefore, independent power operation systems have been built on the outskirts of major cities that are supplied with larger sources for electricity generation.

There is also a trend to integrate ESS systems and install them by unit block. This makes the process of installing ESS simpler than before. Previously, the battery, power conversion system (PCS), inverter, and transformer (TR) were built separately. But, now various components are packaged together, making installation much more convenient.

Accordingly, many companies are entering the ESS market, followed by standards and certification specifications for products being established. In the future, we will need a comprehensive mechanism that integrates and controls multiple systems and standards, along with discussions regarding battery efficiency.

Codes and standards are important in battery field

As the demand for product standards and certification specifications grows across a variety of industries, codes and standards are becoming more important in ESS.

Codes refer to regulations or standards that comply with laws. It is illegal to launch a product that does not meet the codes on the market.

Standards are the minimum indicators that serve as technical standards and design references. Typically, standardization is performed by the Institute of Electrical and Electronics Engineers (IEEE)* and the International Electrotechnical Commission (IEC)*.

*IEEE (Institute of Electrical and Electronics Engineers): An American Institute of Electrical and Electronics Engineers, the world’s largest gathering of technical experts.

*IEC (International Electrotechnical Commission): An organization established in Geneva, Switzerland in 1906 for standardization in the electrical and electronics fields.

Then, what is the purpose of creating codes and standards? The most fundamental one is to establish standards to ensure product safety.

All components, such as bolts and screws, that are used in products have set standards. Thanks to standardization, you can easily fix an imported product by getting the parts necessary in your own country. However, without standardization, you may have to request parts from the overseas manufacturer and wait for them to arrive to fix the product. We create codes and standards to prevent these problems, reduce economic losses, and strengthen safety. Accordingly, conforming to codes and standards means meeting not only the design specifications of the product but also safety and performance, while it also means passing acceleration testing under specific conditions.

What codes and standards exist for ESS?

An analysis of the US market shows that approximately 9,000 components are used in ESS container solutions. There are standards not only for each component but also for a comprehensive solution.

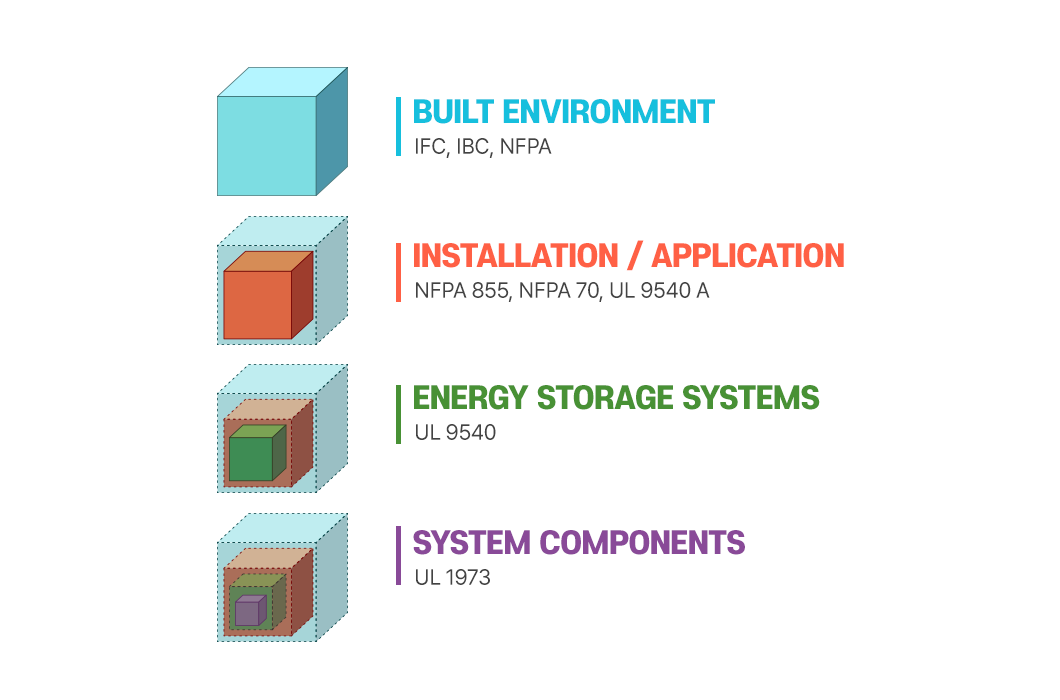

First, the surrounding environment, such as the building, must be considered. Recently, standards such as the International Fire Code (IFC) and the International Building Code (IBC) are also drawing attention. In addition, the standards established by the National Fire Protection Association (NFPA), an American fire protection association, are also widely used.

ESS should not only conform to codes and standards at the production level but also at the installation level, where codes and standards such as NFPA 855, UL* 9540, UL 9540A, and NFPA 70 are applied.

At the stationary BESS level, UL 9540 is applied as the most representative ESS-related standard. But, at the system component level, it must comply with UL 1973. As the North American market requires the UL standard to be met, it is reviewed to determine whether a product meets the standards through testing to obtain certification.

* UL (Underwriters Laboratory): An international safety certification testing company, established in 1894 by the American Insurance Association, that researches standards for safety-related products and systems.

LG Energy Solution thoroughly implements ESS codes and standards

Multi-layer ESS architecture

An ESS structure commonly refers to a structure where battery cells are gathered to form modules and packs that are then stacked and combined to form a rack. If BMS is included in the rack, it becomes the smallest unit of a battery system.

Also, because it is a battery, direct current (DC) is produced, and the DC output is converted to AC output in the rack. The power can be converted thanks to the power conversion system (PCS). Simply put, a PCS is an inverter that converts power into another form. Currently, the ESS market uses large-capacity inverters of several MW. This is the basic structure of ESS.

ESS can be split into multiple layers. It consists of the primary subsystem, which is a collection of battery subsystems such as PCS, and the control subsystem, which includes BMS and EMS (Energy Management System). There is also a transformer that adjusts the voltage range, and lastly, the auxiliary subsystem, such as thermal management and firefighting.

Providing more reliable products by complying with safety standards

Among many standards, the UL Standard is one of the most widely used certifications in the United States. Safety standards based on this include UL1973, UL 9540, and UL 9540A. Cells, modules, and racks go through safety and fire testing to be certified with these standards.

In particular, UL 9540A tests the fire safety of products to determine their characteristics against fire. It reviews the amount of heat measured in the passage, the components of the gas discharged, the size of the flame, etc. Then, the test results are reviewed by various organizations to be used to obtain an installation permit and certification and to sign up for insurance.

At the installation level, the UL 9540A test is carried out in a place that is almost similar to where the actual ESS will be installed. At this point, it checks the amount of heat generated and the spreadability of the fire along the escape route. Based on the result, how close the battery should be installed is determined. In other words, it is not only the battery but also the whole system that is reviewed to confirm if it is actually operable considering the impact of the installation location on evacuation.

Currently, in North America, only ESS systems that have obtained a UL 9540A test report and UL 9540 certification can be installed. LG Energy Solution is also conducting all tests individually at internal and external testing laboratories to increase the stability of ESS.

FAT and SAT for enhanced safety

Additionally, there are safety tests conducted at the battery production site, which are FAT (Factory Acceptance Test) and SAT (Site Acceptance Test). Through this, we are checking whether there are any problems with the sub-components at the factory on a system-by-system basis, and are performing additional tasks to check what the operating characteristics are in the state of installation.

NFPA, standard for fire protection

There are also cases where codes and standards created by authoritative non-profit organizations, such as the National Fire Protection Association (NFPA), are applied, which mainly include NFPA 855, NFPA 70, NFPA 68/69, and NFPA 72. In particular, NFPA 855 includes design requirements for fire and explosion prevention as well as structural aspects in terms of evacuation. It then requires safety specifications for overall ESS products and installation, including fire detection and ventilation systems.

LG Energy Solution carefully reviews these standards and specifications in designing ESS products and releases them on the market after a series of tests. Through these efforts, LG Energy Solution’s ESS Battery Development Center plans to provide a differentiated customer experience by providing a variety of ESS solutions that can satisfy customers, ranging from solutions of hundreds of MWh to hundreds of GWh.