Hybrid electric vehicles (HEVs), plug-in hybrid electric vehicles (PHEVs), battery electric vehicles (BEVs), and the recently popular commercial electric vehicles – they all have batteries in them. Indeed, it can be said that a battery is one of the key factors that determine the vehicle’s performance. Having recognized the technology trend early on, LG Energy Solution continued technology development, releasing pouch-type battery cells and modules for EVs.

LG Energy Solution, a leader in EV battery

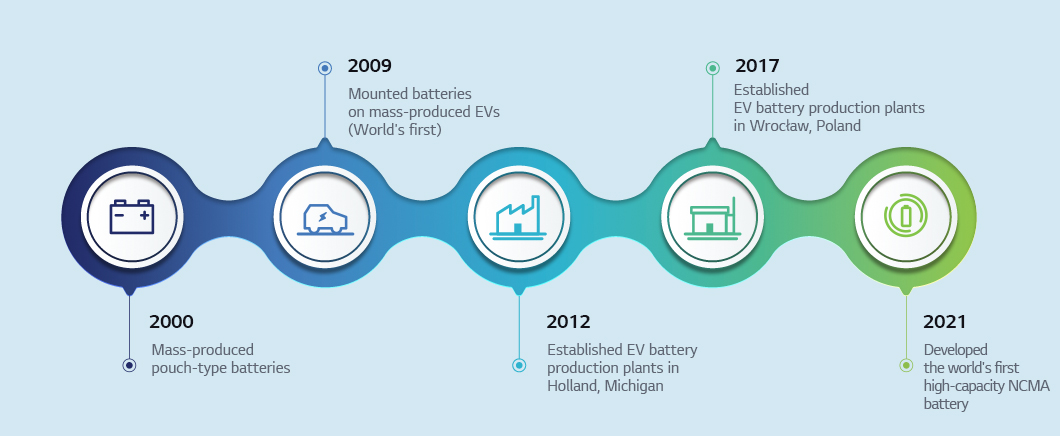

As a pioneer of the EV battery industry, LG Energy Solution has gone beyond dominating the South Korean market and now is a global leader in the sector. The battery maker began its EV battery business with mass-production of pouch-type batteries in 2000 and supplied batteries for mass-produced EVs for the first time in the world in 2009. It went on to bolster its global status by building EV battery-production plants in Holland, Michigan of the U.S. in 2012 and then in Wrocław, Poland in 2017. The company’s innovation did not stop there. In 2021, it put itself in the limelight by developing the world’s first high-capacity NCMA battery.

Such proactive moves enabled LG Energy Solution to make notable achievements in the EV battery market. It has had 79 EV projects with 31 global car manufacturers. In doing so, it has expanded its portfolio, ranging from cell to pack. A total of 912 million cells have been installed in 7.376 million HEVs, PHEVs, and EVs since 2009.

LG Energy Solution’s innovative battery technologies

LG Energy Solution is establishing itself as a top-tier battery maker in the global EV market. It is producing EV batteries based on its technological prowess. What would be its technologies?

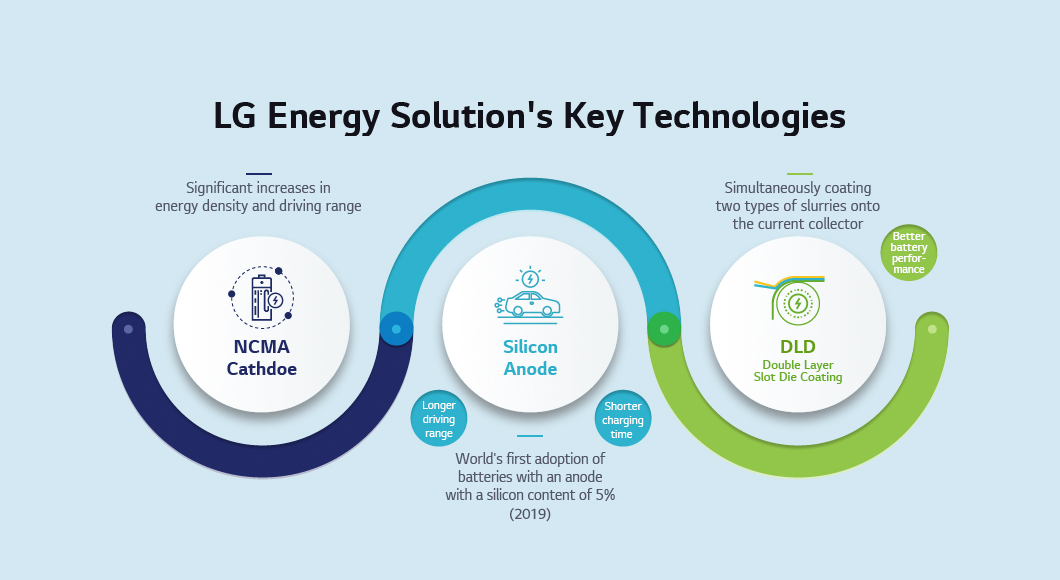

First, LG Energy Solution uses differentiated cathode and anode materials for its lithium-ion batteries.

LG Energy Solution’s lithium-ion battery consists of NCMA (nickel, cobalt, manganese, aluminum) cathode because that can improve the energy density and the driving range significantly. A higher nickel content means a higher battery capacity and density, and a higher aluminum content means a higher battery stability.

The battery maker’s anode contains silicon, a next-generation material. LG Energy Solution produced the world’s first EV battery that has an anode with a silicon content of 5% in 2019. A silicon anode not only shortens the charging time but also improves the driving range.

In addition, LG Energy Solution produces batteries using innovative manufacturing technology.

In the coating process of battery manufacturing, Double Layer Slot Die (DLD) technique is employed. Generally, a slurry in which active materials and solvents are mixed is thinly coated onto copper and aluminum foils through a coater (a coating machine). On the other hand, the DLD technique enables the simultaneous coating of two different types of slurries onto the current collector, helping to spread the binder evenly, and which helps improve the battery performance.

Various pouch-type battery cells and modules made with LG Energy Solution’s technologies

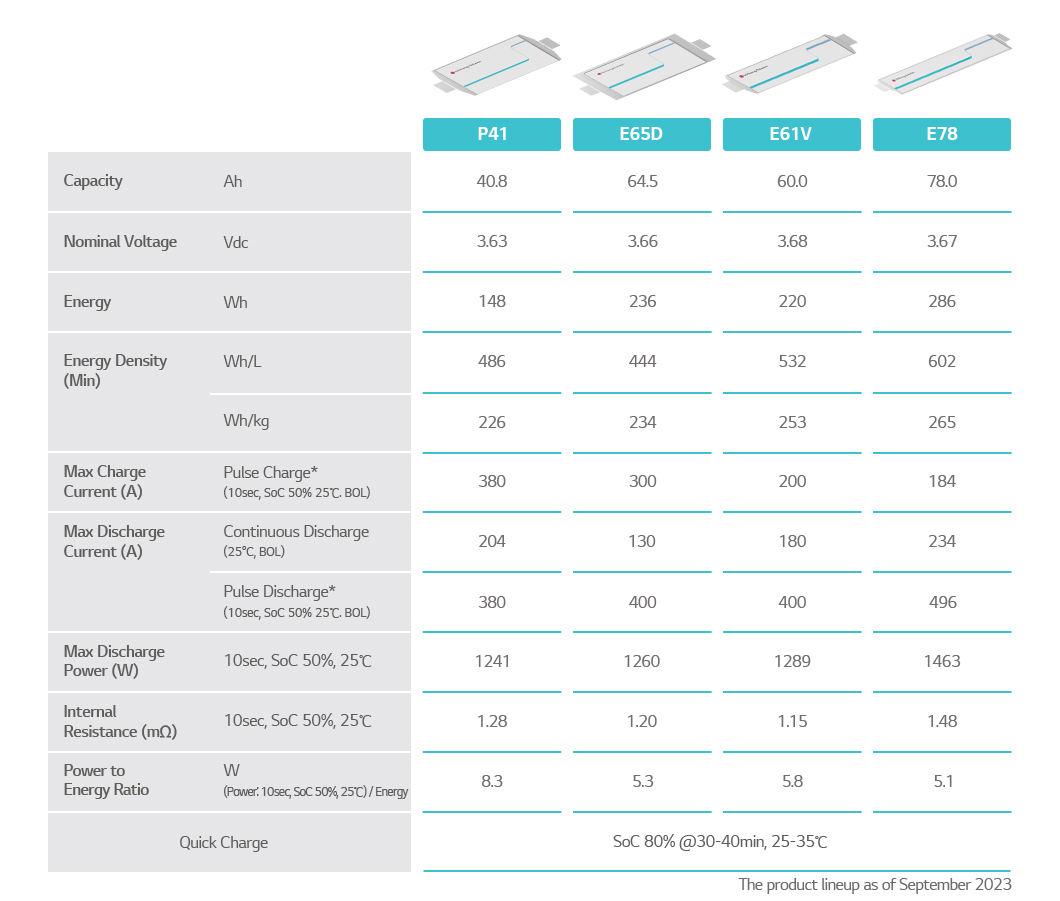

LG Energy Solution harnesses its advanced technologies to produce pouch-type battery cells. In particular, pouch-type batteries can enhance the performance of EVs since they have higher battery density than their cylindrical cousin. Also, they can come in a variety of sizes and widths. Therefore, customizing batteries for different uses is easier with these batteries.

What would be the characteristics of LG Energy Solution’s pouch-type battery cells? They have high energy density and offer strong power, maximizing the battery performance. This means that they have enough energy for long-range drive and have higher energy efficiency as they offer high output for better performance. Lastly, they allow diverse designs, a trait that is useful for producing customized batteries.

All the characteristics are featured in the total of 4 pouch-type battery cell products of LG Energy Solution. The P41 is in the power cell line, and the energy cell line has the E65D, E66C, and E78.

LG Energy Solution also releases modules and sets of multiple pouch-type battery cells. Its modules come in small, but perfectly workable sizes, with the flexibility to change the sizes and widths. Also, they can make diverse combinations, a feature good for customized design for EV batteries. They are even equipped with an efficient cooling system.

Its module product line consists of 4 products: the P28.5 and the E66C for short modules; the E78 for a long module; and the E60 for a low-height module.

We have covered LG Energy Solution’s main achievements and key technologies as it is setting the standard with continued development and innovation in the global EV battery market. As we did so, we also learned the battery maker is unveiling a variety of pouch-type battery cells and modules with such capabilities. LG Energy Solution will keep pursuing technology innovation for pouch-type batteries.