Some things enhance the quality of our life by making our days more convenient. Batteries are among those that first come to mind. Behind the scenes, they are created through a combination of multiple technologies and several manufacturing processes. Let’s take a look at the first step of battery manufacturing, the electrode manufacturing process.

Mixing – producing slurries by mixing active materials

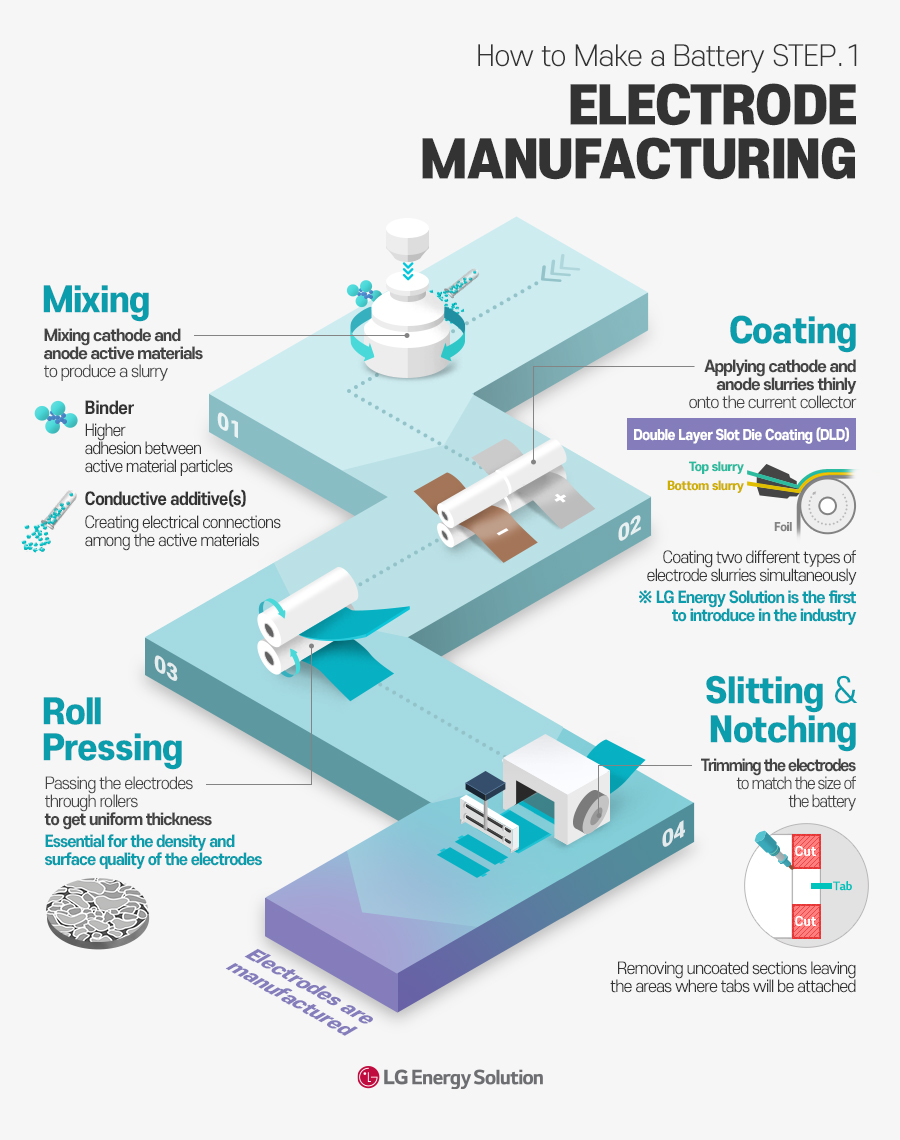

The electrode manufacturing process is about making the cathode and anode, the bases of batteries. It consists of mixing, coating, roll pressing, and slitting & notching, in that order. In the first step of the process, mixing, ingredients for making the cathode and anode are measured and mixed to produce slurries.

To make a slurry, binders are added to enhance adhesion between electrode active material particles. Then, conductive additives are incorporated to facilitate electron transport between the active material particles.

Coating – coating slurries onto current collectors

In the coating process, cathode and anode slurries produced in the previous mixing process are coated onto aluminum and copper foils respectively. Then, the coated electrodes are dried in at least a 100°C oven, a step that improves the battery life and performance.

The Double Layer Slot Die Coating (DLD) method developed by LG Energy Solution for the first time in the world in 2018 allows coating two different electrode slurries onto the current collectors at the same time. DLD strengthens electrodes by determining the top and bottom electrode features selectively, as well as improving charging speed and battery performance.

Roll pressing – evenly flattening electrodes

Also called the rolling process, this is a process where the electrode goes through two rolls and gets evenly flattened. As two big rolls press the electrode from both sides, spreading it thinly and boosting its density, the electrode surface bonds to active materials better. Then, lithium ions travel more easily through the well-connected active materials, enhancing battery output and performance.

The electrode density in the roll pressing process is determined by mixture density.

*Mixture density refers to how well the materials are pressed.

Slitting and notching – cutting electrodes to fit the batteries

The electrode flattened in the roll pressing process needs to be cut to fit batteries in the slitting and notching process. The two-phase process includes first cutting the electrode vertically (slitting) and then making a V-shaped notch and tabs to form positive and negative terminals (notching). In notching, uncoated parts where cathode and anode active materials are not applied are cut out using notching devices, leaving the corners where tabs will be grounded.

If you have gone through the five steps of mixing, coating, roll pressing, slitting, and notching, you are done with the electrode manufacturing process. We have discussed the electrode manufacturing process where the cathode and anode of a battery are created.