Ceramic is earning attention as a core material of EV battery separator. This time, we will learn the origin, properties, and uses of ceramic, which is used increasingly widely.

Etymology

The word “ceramic” originates from the ancient Greek word κεραμικός (keramikos), or “clay stuff made by firing at a high temperature.” The sculptures and pottery made by baking clay in the prehistoric era are the earliest ceramic items. From early earthenware to an essential part of modern lives, ceramics have been one of the materials with the longest history with humans.

Properties

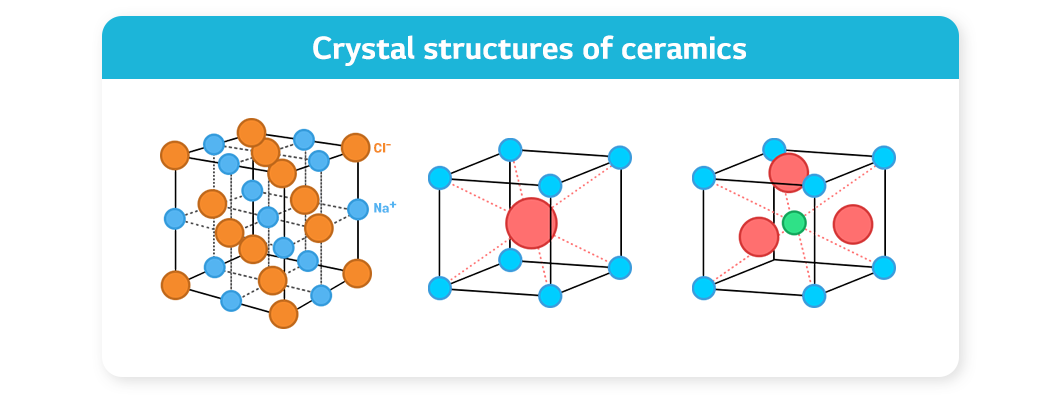

Ceramic is a non-metallic solid formed by combining metallic elements, oxygen, nitrogen, and carbon, and firing it at a high temperature. What matters, in particular, is the ionic bonds. The crystal structures of ceramics can vary depending on the amount of the charge of ions consisting of the material as well as the sizes of the cations (metal) and the anions (non-metal). Ceramics are hard and can withstand temperature changes. Also, ceramics can prevent corrosion from strong acids and bases.

Uses

Ceramic is applied to make many commonly used products such as pottery, cement, glass, and tiles. These days, they are also used in the state-of-the-art industry. In particular, “Fine Ceramics,” improved through research, have advanced mechanical, chemical, electrical, and heat-resistant properties. They are used widely for electronic parts, artificial teeth and bones, and insulators in the aerospace industry.

SRS® (Safety Reinforced Separator®)

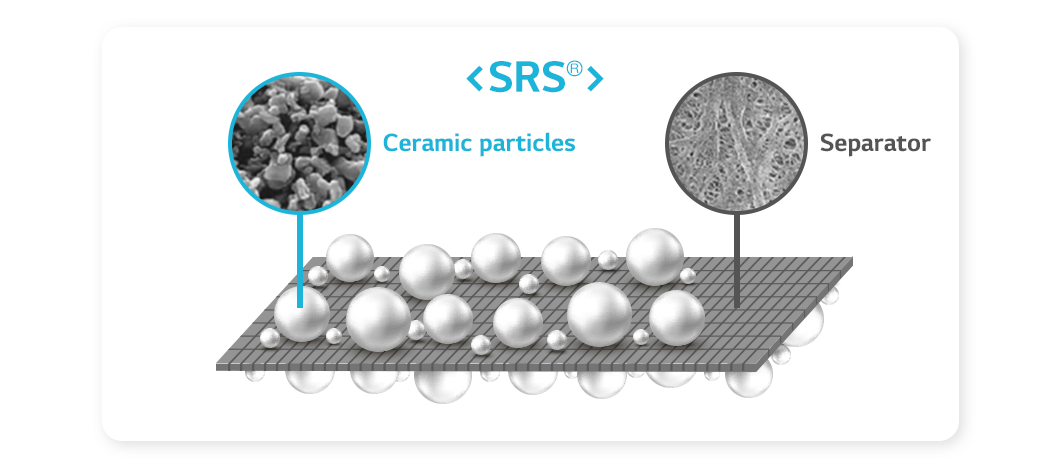

Ceramic materials are used for battery manufacturing as well. Ceramic particles and polymer binders improve battery durability and heat resistance further when coated onto the surface of the separator that contributes to battery safety. The Safety Reinforced Separator (SRS®) technology of LG Energy Solution is applied to this. Currently used separators lose durability at temperatures of above 100 degrees, however, SRS® can withstand high temperatures of over 200 degrees. Because of this feature, high-performance and safety can be ensured even when it is applied to energy-dense and high-output high-nickel batteries.

We have covered the features of ceramic that have been used in various areas from our daily lives to cutting-edge science and battery manufacturing technology. In particular, we could catch a glimpse of the efforts of experts to reinforce battery safety through SRS® developed by LG Energy Solution. We can look forward to the progress of ceramics in various industries!