✍

Professor JunHo Lee

Chair of the Department of Battery-Smart Factory, Korea University

LG Energy Solution and Korea University jointly established the Department of Battery-Smart Factory, the first battery department introduced through an industry-academia partnership in Korea. The “contracted department” ensures students a job when they obtain a degree, which raises curiosity about the study environment. We had the pleasure of meeting Professor JunHo Lee who is also the Chair of the Department of Battery-Smart Factory where future leaders of the battery industry are gathered.

Q. Nice to meet you, Professor! Can you please introduce yourself?

Pleasure to meet you, too. I am Department Chair JunHo Lee of Battery-Smart Factory. We have to do a lot of preparations and consultations for the first industry-academia joint battery department. However, we have high expectations because we are nurturing experts who will support the growth of the battery industry through meaningful challenges. Above all, we believe we can create an ideal talent-fostering environment by strengthening their fundamentals through close cooperation with LG Energy Solution at school, and letting them have on-site experience in the industry. Just thinking about it makes us thrilled.

Q. What contributed to the establishment of the department?

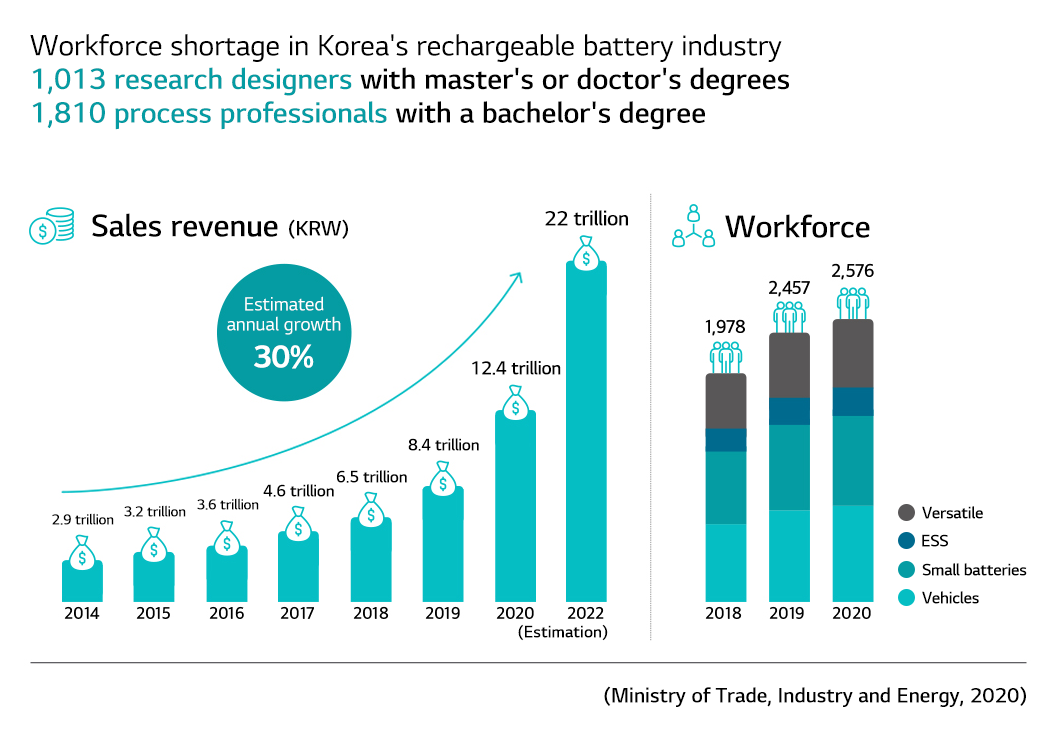

The first reason is demographic changes. As Korea is on track to become a super-aged society, the working-age population is expected to decline to half by 2050. Companies are introducing a contracted department in an industry-academia partnership to recruit talent ahead of others.

Also, the nature of jobs has changed following the Fourth Industrial Revolution, prompting a shift in requirements of businesses. We thought we could offer customized education by reducing the gap between the capability students can get at college and the capability required by the industry. And that might be the beginning of the industry-academia cooperation.

Above all, we needed to move rapidly to nurture experts who will be supporting the explosive growth of the battery industry. Since expanding smart factories is considered as a solution to improving productivity of each worker amid the changing demographics, the Department of Battery-Smart Factory will attract the most attention in education.

Q. The department began accepting students from March 2022. What do they learn?

Students major in “battery engineering” that studies AI-based development of battery materials and future batteries as well as “smart factory” that studies smart factory security, digital twin and process analysis. Curriculums are designed and followed in cooperation with LG Energy Solution. Therefore, students can receive differentiated education where they can strengthen their fundamentals at school and improve practical skills in the field.

The department is recording “failure cases” on a research notepad and plans to develop a big data-based AI navigation to improve expertise and continuity of education. That is to say, we will share an AI-based digital notepad that gives a quick answer browsing the failure cases it has in its database. If students have the results but do not know how to get the results, they will be wasting their time repeating the same failure their predecessors have made. By sharing data, we can eliminate the barriers between researches and departments, which can lead to improving the efficiency of the project and setting a clear direction. This is the same practice employed by businesses where the barrier between different departments has to be removed. They can grow creativity and expect high performance only after letting the departments share data.

Q. Are there special advantages for the students? If so, what would that be?

Students of the department are qualified for full scholarships and living expenses given by LG Energy Solution for their 4 years of doctoral program or 5-6 years of combined program for master’s and doctoral degrees. In particular, they can seize the chance to grow to be a globally competitive engineer ahead of others in the battery and smart factory sectors that need more experts to support the rapid growth.

Q. What changes do you expect to happen at LG Energy Solution as a result of the education?

The cooperation between university and industry has enabled more practical research. Therefore, we expect we can identify potential issues at the early stage of development and accelerate development of new battery materials. Also, we believe we can build a local employee training system by developing a virtual simulation system using digital twin technology. With this, we can dramatically reduce the time and costs of training.

Also, research at the smart factory produces process technologies. They will enable LG Energy Solution to build and operate plants across the world employing intelligent automation. Then, we can further decrease risks and the time for dealing with the required quantity from clients.

Q. As an expert in battery and smart factory, what do you think is LG Energy Solution’s competitive edge?

Smart factories cannot be introduced to existing plants. LG Energy Solution is building them from the ground up on overseas sites. That is their advantage. They have to start everything from the beginning and therefore have enormous possibilities and are capable of realizing a true smart factory.

I would like to quote Tom Peters here. In his book In Search of Excellence, he said you have to start first and then aim, not the opposite, to hit the target. It is the same with the basic concept of AI technology. And also, it could be something the Department of Battery-Smart Factory and LG Energy Solution has to remember at a time to pioneer new territory.

※ The views expressed are the writer’s alone and do not necessarily reflect the opinion or strategy of LG Energy Solution.