On March 16, LG held the LG Tech Conference, where 350 R&D experts from local master’s and doctoral programs in science and engineering learned about the current state of different technological innovations. LG shared its vision for the future in 26 technology sessions, including AI, big data, and blockchain. Among them, there has been a lot of interest in smart factories and AI application cases, two of the buzzing areas of the fourth industrial revolution. Let’s take a look at the presentation given by Jun-ho Lim of the AI Technology Team, who uses AI in many different fields, from production to reducing defect leakage.

Smart Factory, Connecting All Processes From Ordering to Receiving Goods

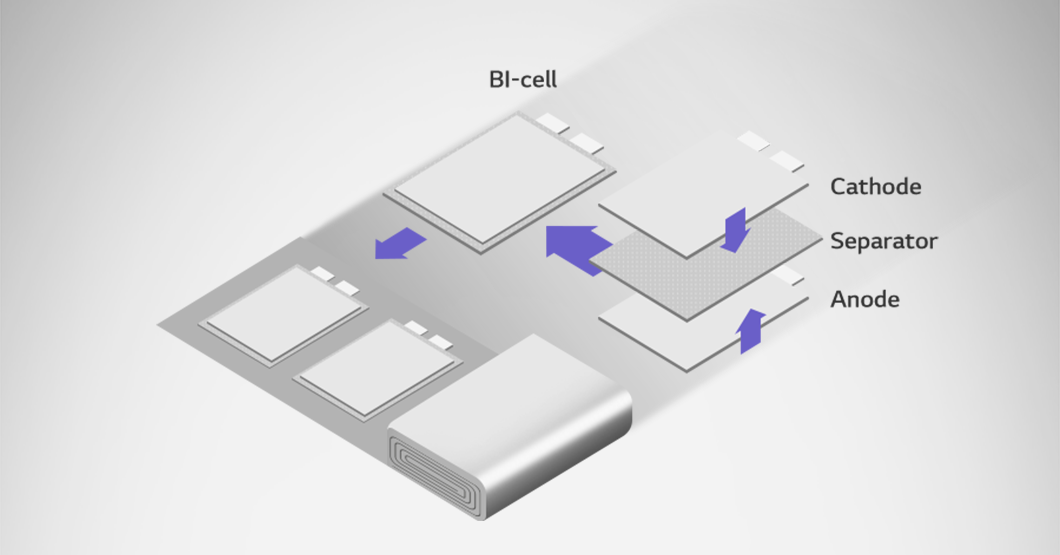

A smart factory uses a network to connect and automate the entire production process, including design, development, manufacturing, and distribution. By applying this to LG Energy Solution, the whole process can be carried out efficiently, from battery design to production and delivery. For example, instead of manually inspecting the battery with the human eye, AI detects it automatically, making the process faster and more efficient.

Identifying defects in ordinary products may appear to be a simple task, but it is a difficult task for algorithm developers. A particular issue in classifying good and bad data is the lack of bad data. In this regard, I’d like to talk about two challenges we worked on when integrating AI technology into the production process, especially concerning the leakage of defects.

Using Anomaly Detection to Secure High-Quality Goods

The first task is to use an anomaly detection model to find new defects that appear during package welding to reduce defect leakages. The package welding process, which welds cathodes and anodes, is part of the battery manufacturing process. After using the lamination and stacking (L&S) method, a pouch-type battery is completed by welding the front and back. Because there is a risk of explosion if foreign substances enter or welding is done incorrectly during the process, very stringent vision inspections are carried out. The use of artificial intelligence in this welding inspection process has the potential to increase efficiency.

While the number of normal images per day can range from hundreds of thousands to several million, the number of bad and abnormal images is extremely small, making it preferable to use anomaly detection to solve the problem. When the study was carried out in 2017, the AutoEncoder method was primarily employed. When an input image is entered, the same image is reconstructed as a result, with the goal of minimizing loss. This method assumes that if a normal image is entered, the difference between the input image and the network’s output image will be small. On the other hand, if an abnormal image is entered, the difference between the input image and the output image will be large. However, the performance, in this case, was poor. This is because there is no guarantee that a network trained solely on normal images will be unable to reconstruct abnormal images. Another disadvantage was that it had to be trained every time a new normal image was received.

Therefore, an anomaly detection method without retraining increases operational efficiency. A model trained on a network that classifies different classes can extract various features. So, it can improve performance and operational efficiency by using feature extraction based on a pre-trained network.

Class-Imbalance and Solution

Once a defect has been identified, it is necessary to locate it as well as investigate how to fix it and what caused it. Following that, appropriate action must be taken. To that end, images were classified. The number of bad images varied by class, creating an imbalance that hampered performance. In general, research papers or results appear perfect because the number of images for each class is the same, but this is not always the case. In other words, when it comes to classification, it is commonly assumed that the number of images is the same. However, in reality, the number of defects is small, and to make matters worse, the number of data sets for each class of defects is even smaller, resulting in severe class imbalance.

As a result, we automated the measures for improvement that were based on the engineers’ experience-based judgments. Because field engineers use domain knowledge to classify defect types and estimate location, their different proficiency levels result in a difference in analysis time and results, resulting in ongoing costs.

We proposed a technique to reduce the class imbalance in automation. This technique limits the number of images that go into one batch during deep learning. But even this didn’t help much to improve performance. There are two main causes of performance degradation in class-imbalance situations: (1) not having enough data to represent all of the classes and (2) easily being biased to minimize loss due to the nature of deep learning.

Therefore, we adjusted the weights of the final layer through normalization. Instead of jointly training the network with the intuition that the weights have similar norms after fine-tuning, the weights were normalized after the general learning phase. The issue with the prior sampling strategy was fixed by using this simple strategy. In fact, performance improved by about 3% when compared to general training. The method can also be used for personal research because it is a simple way of normalizing the final weight after learning.

Where Is the AI Technology Team Headed?

I shared the two projects that AI researchers worked on. There are still many challenges and work to be done in the future. It would be nice if there were algorithms with advanced models that we could easily use, but even in this case, we would need to fine-tune them before using them. Utilizing automatic learning provides significant benefits in terms of maintenance costs. Several studies are needed in this regard.

The AI technology team is a group that uses artificial intelligence to solve problems throughout the company. Artificial intelligence is used in a wide range of applications, from battery design for data-driven materials research (Material Informatics) to manufacturing processes and time series prediction algorithms for raw material price prediction. That is why our team is also conducting a variety of research! Together, we can tackle interesting tasks and research as we develop new values that benefit our modern society.