Electrode manufacturing is a key procedure where the battery cathode and anode are made. And the first step of it is mixing. As its name suggests, electrode materials are measured and mixed in this step; active materials and solvents are mixed, producing slurries.

Mixing Machine

Since the anode active materials (anode materials) have a weak crystal structure, equipment that may apply strong shear stress (the stress applied parallel to a given surface) should be avoided. Therefore, a planetary mill, a machine that looks like the one used when kneading dough, takes the place.

*For the anode active materials, graphite is used here.

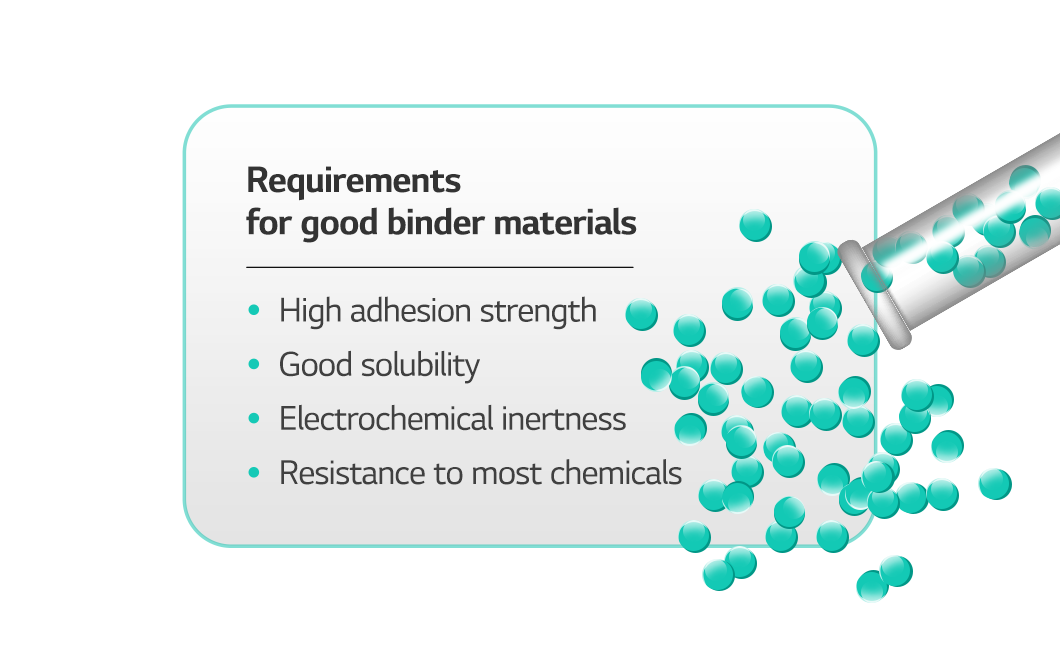

Binder

A binder (a substance that fastens materials) improves adhesion between the particles of the active materials as they are being mixed. It should be stable enough to maintain its adhesive quality even when contacted with electrolyte or an oxidation-reduction reaction occurs. Good binder materials have high adhesion strength, good solubility (in industrial solvents), electrochemical inertness, and resistance to most chemicals.

PVDF X NMP

Polyvinylidene fluoride (PVDF) is normally used for binders, often with N-Methyl-2-pyrrolidone (NMP) as a solvent. This combination creates high adhesion, helps dispersion of conductive additives, and offers stability in oxidation-reduction reactions. Recently, as researchers seek to further increase energy density, styrene-butadiene rubber (SBR) or carboxy methyl cellulose (CMC) are also employed as substitutes. The materials allow raising the proportion of active materials and cutting that of binders.

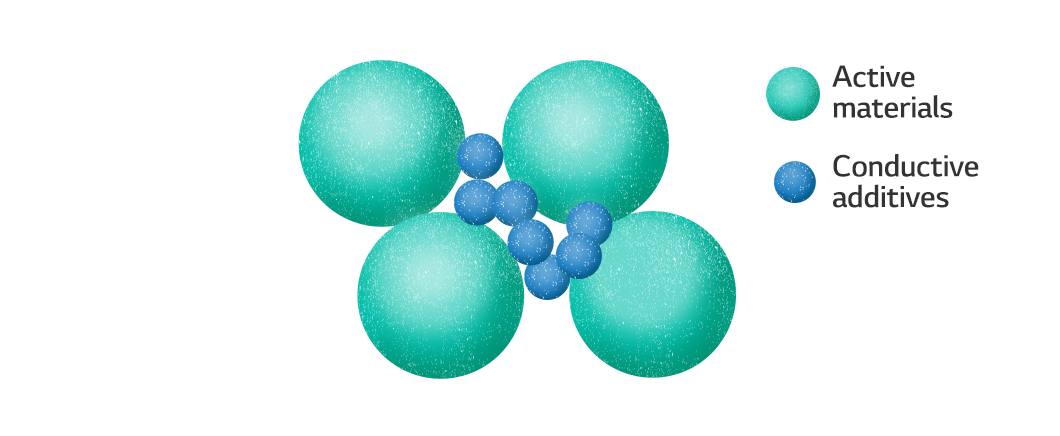

Active Materials and Conductive Additives

The proportions of active material particles of certain sizes (particle-size distribution) can affect the mixing process and the quality of the electrode. Oversized or undersized particles need to be removed since they can produce dust. Also, more point contacts in active materials can cause more holes that can shrink the battery capacity. Those holes can be plugged by adding conductive additives that improve the electrode conductivity.

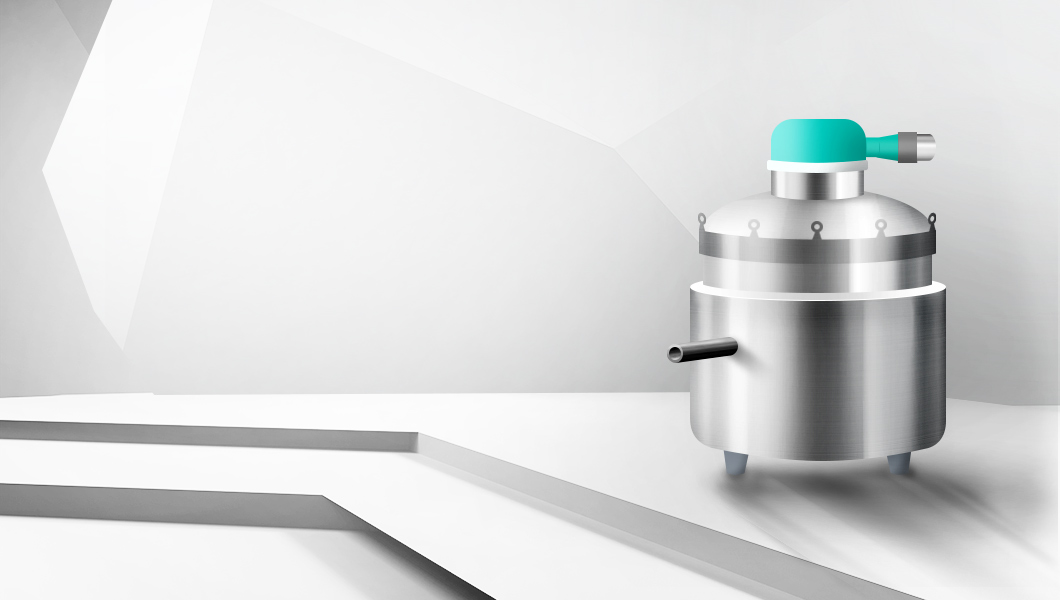

Dreamline 2.0

In conclusion, the mixing process involves combining electrode active materials with binders, solvents, and conductive additives to produce a slurry, an intermediate material. Recently, LG Energy Solution announced plans to implement Dreamline 2.0 at Ultium Cells’ manufacturing facilities, a joint venture with General Motors. This upgrade will expand the capacity of the mixing equipment to 3,500 liters, aiming to increase battery yield and enhance the efficiency of the mixing process.

We have examined the mixing process, the first step of electrode manufacturing in making batteries. Next time, we will find out what happens to the slurry in the “coating” process, the second step of electrode manufacturing!