LG Energy Solution adopted an innovative coating technique for anode slurry for the first time in the world in 2018, enabling fully charging an EV in just 20 minutes. This technique is called “Double Layer Slot Die Coating (DLD).” Today, we will look at what it is and how it is reshaping the future of EVs.

What is DLD?

To know the technique, we first need to understand the “electrode manufacturing process,” a basic process in making a battery. Simply put, the process is for producing the cathode and anode in order of: “mixing” where electrode materials are mixed; “coating” where the resulting slurry is spread out onto a foil and dried; “roll-pressing” where the coated electrodes are compressed to reduce the thickness; “slitting” where the flattened electrodes are cut; and “notching” where tabs are added to the electrodes.

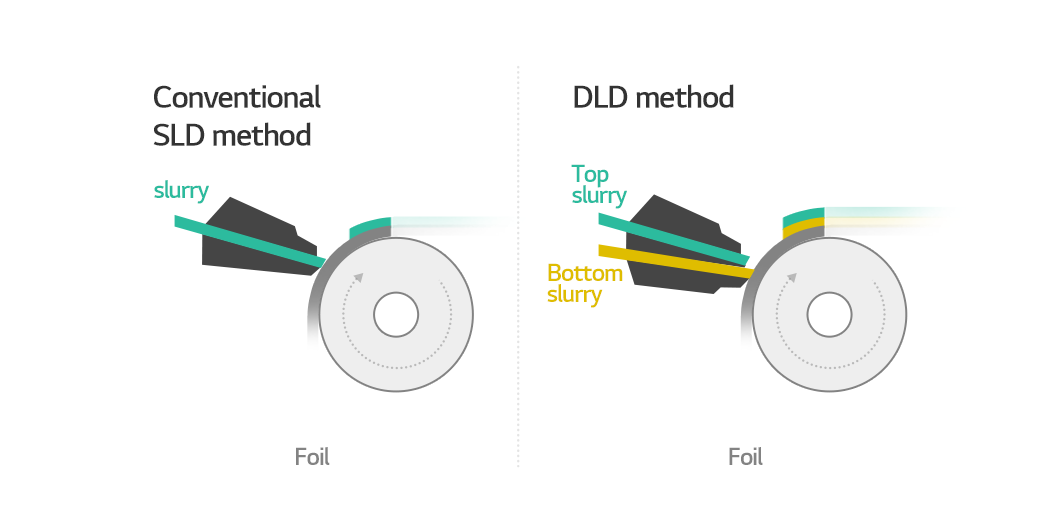

DLD is employed for the coating process. A slurry is made by mixing battery constituents including active materials and solvents in the mixing process, and then a coater applies it onto copper and aluminum foils in the coating process. DLD is a technique for coating two types of electrode slurries* onto the current collector simultaneously.

*Electrode slurry: A mix of an active material, binder, conductive additive and solvent.

Why DLD is gaining attention

DLD is also called “coating platform” technique, because it allows using two types of slurries and determining the top and bottom electrodes selectively to fit the purpose, which helps strengthen the electrodes.

This method offers higher efficiency of the binder than the conventional way of using one type of slurry, improving the physical properties of the electrodes and reducing the internal resistance of the battery, which in turn, cuts charging time and increases the battery’s performance. So, “a complete charge in 20 minutes” becomes possible when fast-charging an EV.

Beyond being the first

LG Energy Solution became the world’s first to adopt the technique for anode slurry in 2018. Since then, the battery maker has used it for most EV batteries it produces, enabling fully charging an EV in just the time you can listen to 6-7 songs. Indeed, there has been a strong demand for a shorter charging time with the growing popularity of EVs. So, commercialization of DLD method would be good news for would-be EV owners. But LG Energy Solution did not stop at being the first and has continued to make efforts for the improvement and safety of batteries. You can look forward to seeing its future innovations.