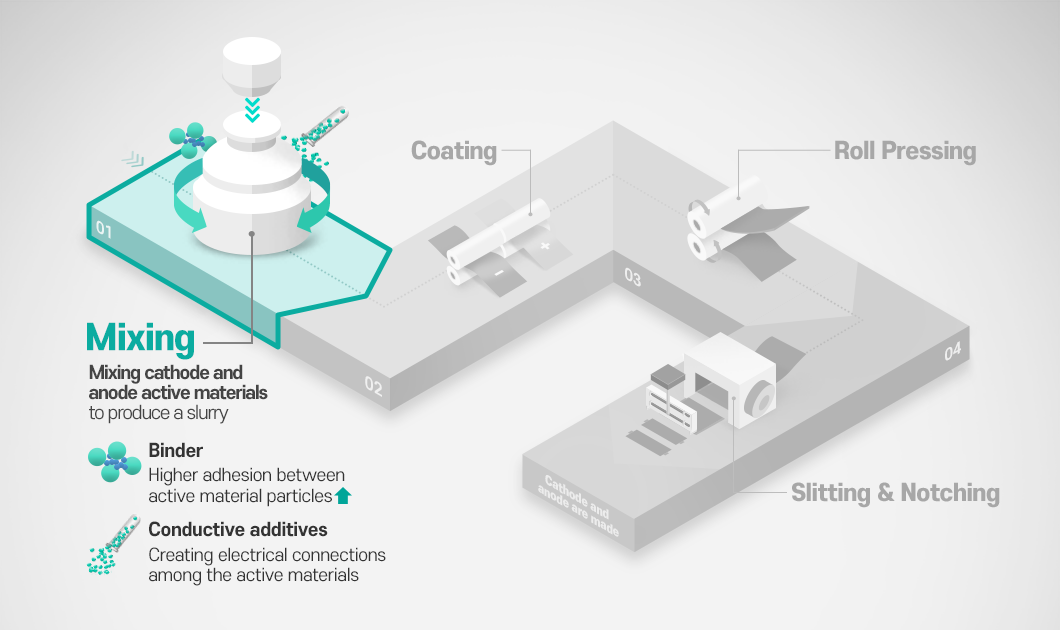

The cathode and anode of a battery are manufactured through the electrode process, which begins with mixing process, where various raw materials are combined to create a liquid slurry. Uniform dispersion of the slurry is crucial for optimizing performance. In this session, we will examine the “pre-dispersion process,” a key step of mixing that produces a uniform slurry and determines battery performance and quality.

The Components of Slurry, the Fundamental Material in Electrode Manufacturing

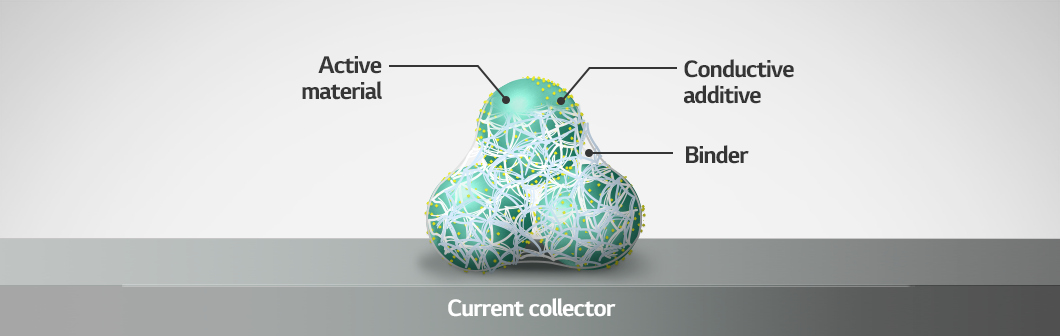

The mixing process is the first step in electrode manufacturing. In this process, additives such as binders, conductive additives, and solvents are combined with the active material, the key component of battery performance, to produce a liquid slurry, the fundamental material of the cell.

First, the active material is the substance that chemically reacts within the electrode to generate electrical energy. The cathode active material provides lithium ions to the anode during battery charging, while the anode active material stores and releases these ions during discharging.

*Learn more about active material

The binder is a material that enhances adhesion between particles and between particles and the current collector, allowing them to remain fixed within the active material. It helps maintain adhesion stably even when in contact with electrolytes or during the redox reactions that occur within the electrode.

Finally, the conductive additive facilitates electron movement and improves electrical properties by connecting active material particles. Types include he most widely used carbon black, conductive graphite, carbon nanotubes (CNTs), and graphene. Among these, CNT additives are in the spotlight, as they offer superior conductivity with smaller amounts compared to conventional conductive additives.

*Learn more about carbon nanotube additive

Pre-Dispersion: What Makes Subtle Differences in Battery Performance

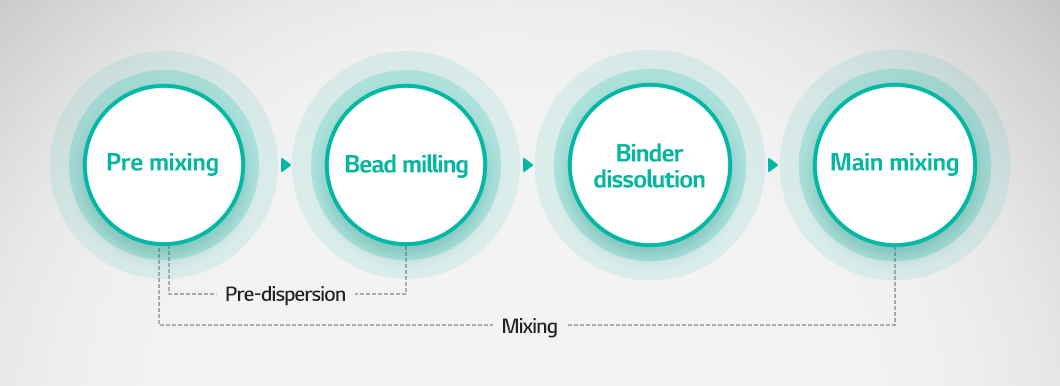

The pre-dispersion process is one of the sub-steps of mixing. It is a pre-treatment stage in which conductive additives are evenly dispersed to improve electrode conductivity.1 It typically consists of a pre-mixing process, where conductive additives, dispersants, and solvents are combined, and a bead mill process, where the pre-mixed solution (pre-dispersed liquid) is further dispersed using beads. These early-stage processes help enhance slurry quality.

Next, a binder dissolution process is carried out prior to main mixing, in which the binder is dissolved in a solvent to distribute the binder evenly within the slurry. After this, the pre-dispersed conductive additive liquid, dissolved binder, and active material are measured in and mixed at appropriate speeds (rpm) and durations during the main mixing step, completing the slurry.

Meanwhile, the specific sequence of powder input and mixing in this process may vary depending on the manufacturer and the characteristics of the mixing equipment. In addition, temperature and mixing speed can also affect slurry properties. For example, if the temperature rises excessively during mixing, the pre-dispersed liquid or slurry may undergo gelation, weakening its dispersibility. Conversely, if the mixing speed is too high, excessive shear force may be applied, potentially damaging delicate active material particles. Therefore, the mixer’s performance, key process parameters, and appropriate mixing sequence must be carefully designed in consideration of the target battery characteristics and production scale, and meticulously managed through real-time monitoring.

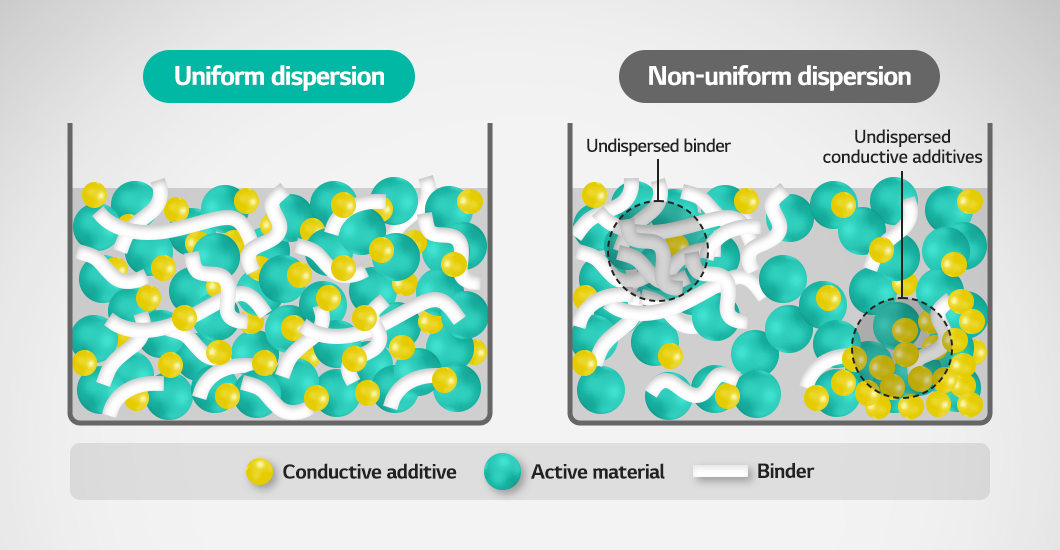

So, why is it important for conductive additives to be uniformly distributed?

Conductive additives generally tend to form agglomerates and have low solubility and dispersibility. In particular, CNT additives, which are gaining attention as alternatives to conventional carbon black additives, experience strong van der Waals forces2 between CNTs, causing them to bundle together in solution. If such agglomerates remain in the slurry, the conductive additive (CA) network3 cannot form properly, and electron conduction pathways may be disrupted. As a result, electrical resistance increases, which can lead to degradation of battery performance.

To prevent these problems, a pre-dispersed liquid is produced by mixing conductive additives, dispersants, and solvents. This liquid helps active materials, which are added later in the main mixing process, disperse uniformly and also contributes to the formation of uniform electrode thickness and density during the coating process. Therefore, pre-dispersion is a critical step that must be carried out beforehand to enhance electrical conductivity and battery performance.

Major Methods of Pre-Dispersion

1) Physical (Mechanical) Dispersion: This method applies physical (mechanical) energy, such as shear force or impact force, from the outside to break the bonding between particles and allow powder particles to disperse evenly in a liquid. It is currently the most widely used method due to its relatively low technical difficulty. However, while this physical dispersion method can reduce the size of agglomerates to some extent, it has limitations in completely breaking apart entangled particles. The most common methods include the bead mill4 and jet mill5, and ultrasonic vibration energy is also used to achieve finer particle dispersion.

2) Chemical Dispersion: This method involves treating the surface of conductive additives with acid or using surfactants. Its technical difficulty is considered moderate, but it can cause defects on the surface of conductive additives (especially CNTs) or increase the viscosity of the solution, which may result in reduced electrical conductivity and other property degradation.

3) Use of Dispersants: This method employs dispersants such as cellulose-based compounds (e.g., CMC) and vinyl- or acrylic-based compounds (e.g., PVP), and is considered the most technically challenging dispersion method. In this approach, dispersants adhere to the surface of particles, helping to disperse conductive additive particles. However, further research is needed to develop optimal dispersants, as different types of dispersants may influence the slurry properties.

With the expansion of the mid-to large-sized battery market for EVs and Energy Storage Systems (ESSs), the proportion of active materials within electrodes is also increasing. As a result, the role of binders and conductive additives that deliver high performance in small amounts is becoming more critical. The pre-dispersion process effectively disperses these materials uniformly, making its optimization essential. Continued research and development of new dispersion technologies are expected to further enhance the performance of secondary batteries.

- Conductivity: The ability of a substance to conduct electricity ↩︎

- Van der Waals forces: Attractive or repulsive forces between molecules or within parts of a molecule. ↩︎

- Conductive Additive (CA) network: A network structure formed by conductive additives in the electrode. When conductive additive particles are well connected to each other and form a network, electrical conductivity improves. ↩︎

- Bead mill: A device that uses spherical beads to grind and disperse particles. ↩︎

- Jet mill: A method that uses high-pressure gas to cause particles to collide with each other and disperse. The particles are accelerated by the gas speed and reduced in size through repeated collisions. ↩︎