A battery’s electrodes are divided into the cathode and the anode. The chemical reactions 00between them generate electricity, which is a battery’s core function. Therefore, the electrode manufacturing process for both the cathode and anode is crucial.

There are currently two main manufacturing methods for electrodes: the conventional Wet Coating Technology and the next-generation Dry Coating Technology. This time, we’ll break down the key features of these technologies through an easy-to-follow infographic!

Wet Coating Technology: A Widely Adopted Electrode Manufacturing Approach

Electrode manufacturing is the first step in the battery making process, with wet coating technology being the most commonly used method in the industry.

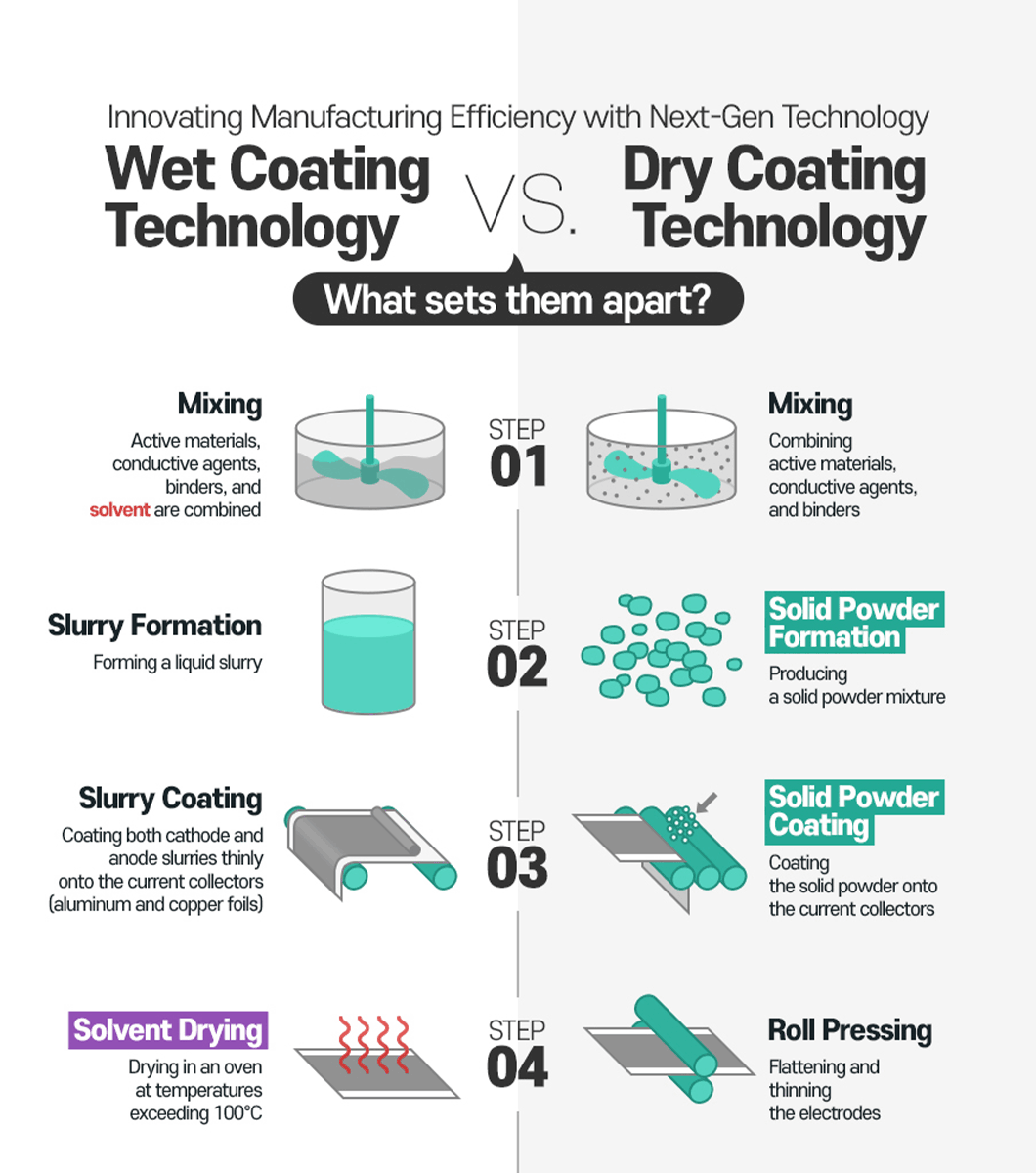

Wet coating technology follows these steps: mixing, slurry formation, slurry coating, solvent drying, and roll pressing.

In the mixing process, the first step, active materials for both the cathode and anode are combined with various raw materials, including a binder to improve adhesion, a conductive additive to aid electron movement and a solvent. These materials are mixed together to create a liquid slurry.

Next, the electrode slurry goes through the coating process. Cathode and anode slurries are then thinly coated onto aluminum and copper foils, respectively. After coating, the slurries are dried in an oven at temperatures above 100°C. This process improves the battery’s performance and lifespan, which makes drying the solvent on the coated electrodes essential.

Finally, the roll pressing process is performed. The electrode passes through rollers to become thinner and flatter. By evenly compressing the electrode and boosting its density, this process improves the bonding between the electrode surface and the active materials, resulting in better battery power output and performance.

Dry Coating Technology: Increasing Manufacturing Efficiency

Dry coating technology consists of mixing, solid powder formation, solid powder coating, and roll pressing.

The main difference from wet coating technology is that the active materials, conductive additives, and binders are mixed without solvents to form a solid powder in the mixing process. This solid powder is then coated onto the current collector. Various coating methods are being researched for dry coating technology, such as the Maxwell method, which laminates the powder onto the current collector after making it into a film, and the powder coating method, which sprays the powder onto the current collector and then roll-presses it. After the coating process, the electrode is completed through roll pressing, just like in the wet coating technology.

Since dry coating technology uses solid powder produced without solvents, it skips the drying step, unlike wet coating technology. This reduces manufacturing time and eliminates the need for equipment for drying and recovering solvents. As a result, dry coating technology offers advantages such as faster production, higher efficiency, and lower electrode manufacturing costs.

In addition, optimizing dry coating technology can increase the battery’s energy density. Thicker and denser electrodes lead to higher energy density. In wet coating technology, thick slurry coatings can cause the migration of conductive additives and binders during the solvent drying process, limiting the maximum electrode thickness.

In contrast, dry coating technology facilitates the production of thicker electrodes and ensures a more uniform distribution of binders and conductive additives as it uses solid powder. This allows for a higher proportion of cathode and anode materials while reducing the use of separators and current collectors, ultimately increasing energy density.

LG Energy Solution Leading Technological Innovation with Dry Coating

LG Energy Solution is making significant efforts to develop and implement dry coating technology. By the end of December 2024, the company aims to establish a dry coating technology pilot line at its Ochang Energy Plant. It plans to secure mass production capabilities and begin commercialization by 2028, after various validation steps.

Additionally, the company will continue to finalize its research and development roadmap for the dry coating technology. This includes ongoing studies on dry electrode formation using various active materials and collaborations to develop dry coating technologies for all-solid-state battery manufacturing.

In this Infographics, we’ve explored both wet and dry coating technologies. We’ve learned that while wet coating is currently the dominant method in the battery industry, dry coating is gaining attention as a next-generation technology. Stay tuned to see how these two processes evolve and how they’ll be applied in the future as technology advances.