Battery assembly is a critical stage that determines the final form of the product. For pouch-type batteries, this involves manufacturing the casing, assembling the fundamental units—the cells—and inserting them into the casing. To maximize efficiency, LG Energy Solution has developed and implemented its proprietary Lamination & Stacking (L&S) method.

However, LG Energy Solution does not just maintain existing technologies but continuously explores various manufacturing methods to enhance its competitive edge. As a result, the company has produced its Z-Stacking method by incorporating the strengths of L&S, leading to the development of the Advanced Z-Stacking (AZS) method, which significantly improves battery safety.

AZS, the Fusion of Lamination & Stacking and Z-Stacking

LG Energy Solution’s Lamination & Stacking (L&S) method utilizes mono-cells, which consist of electrodes and separators. They are combined with half-cells that contain separators and anodes. The anode and cathode are then stacked in layers with the separator in between. This improves production efficiency and optimizes internal battery space.

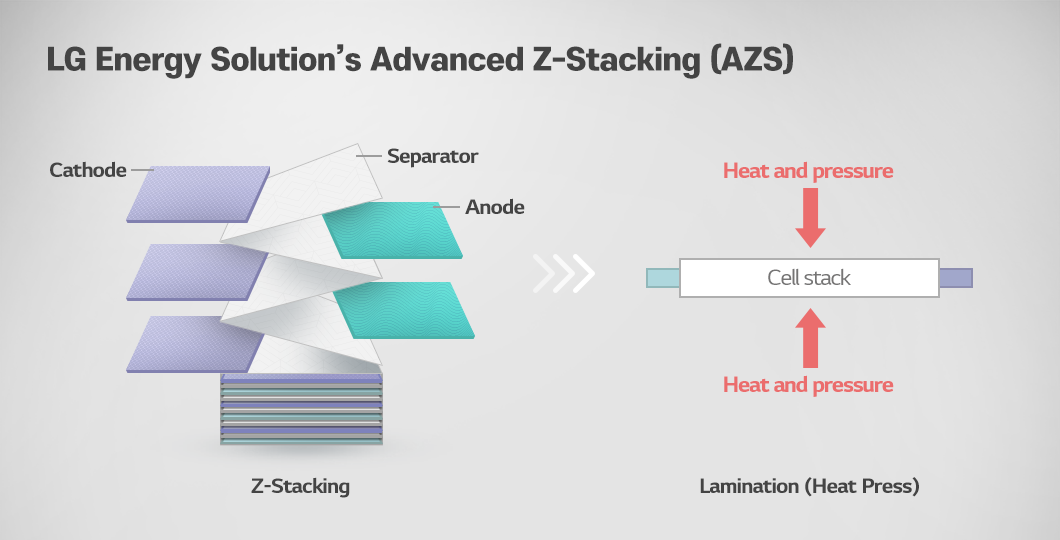

The newly developed Advanced Z-Stacking (AZS) method is a unique manufacturing technique by LG Energy Solution. This innovative method integrates the existing Lamination & Stacking (L&S) method with Z-Stacking.

The key distinction between AZS and traditional Z-Stacking lies in the application of the Heat Press stage. Z-Stacking involves stacking cathodes, anodes, and separators in a zigzag pattern, where the separator is folded in a Z-shape, and individually cut cathode and anode sheets are inserted between the folds. LG Energy Solution has integrated its proprietary lamination technology into this method, utilizing Heat Press to apply heat and pressure, thereby imparting strong adhesion between the electrodes and separators. This has led to the completion of the Advanced Z-Stacking (AZS) method. In the AZS method, electrodes are pre-stacked between the separators and then firmly bonded using LG Energy Solution’s exclusive lamination technology.

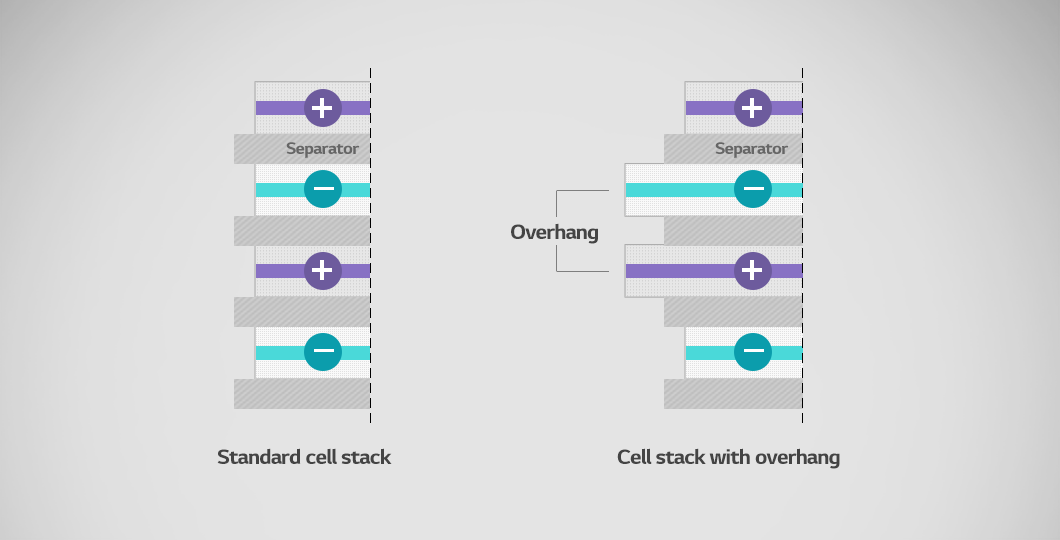

By incorporating the Heat Press stage, the AZS method offers a higher level of safety compared to conventional Z-Stacking. This is possible because bonding the electrodes and separators through heat and pressure ensures precise electrode alignment and minimizes the risk of misalignment. In other words, the AZS method prevents electrode displacement during process transfers and fundamentally resolves the overhang issue, further enhancing safety and reliability.

Additionally, since the cell stack is already bonded together, a larger number of cells can be handled efficiently during process transfers, reducing manufacturing time. Furthermore, equipment can be configured in unit-based modules, optimizing space utilization.

*Overhang: A condition where some electrodes protrude beyond others in a stacked structure.

Mass Production of Batteries Using AZS

The AZS method is currently being employed in battery production. LG Energy Solution has validated the AZS process through pilot line testing and sample production at its Ochang Energy Plant. The technology is now being applied in full-scale mass production at PT HLI Green Power in Indonesia.

Through continuous research into innovative manufacturing methods, LG Energy Solution remains at the forefront of the battery industry. Stay tuned for further breakthroughs as the company continues to lead the way in battery technology!