So far, the improvement in lithium-ion battery’s performance has been driven primarily by advancements in cathode materials. In contrast, anode materials have mostly been limited to graphite, with minor additions of silicon. Meanwhile, high-capacity cathode materials have continued to develop, and the capacity per unit mass of layered metal oxide-based materials is nearing the theoretical limit. This situation aligns with the market’s need for a higher energy density in batteries, drawing attention to anode material innovation as a new solution for enhancing the capacity.

*Curious about the layered structures? View (Infographic #14) cathode material structures here.

Besides graphite and silicon, “lithium metal” is also under research as an anode material. Lithium metal is currently applied to the anode in lithium metal batteries, which are often referred to as next-generation batteries. This time, let’s take a closer look at lithium metal batteries, one of the leading technologies among next-generation batteries.

What is a Lithium Metal Battery?

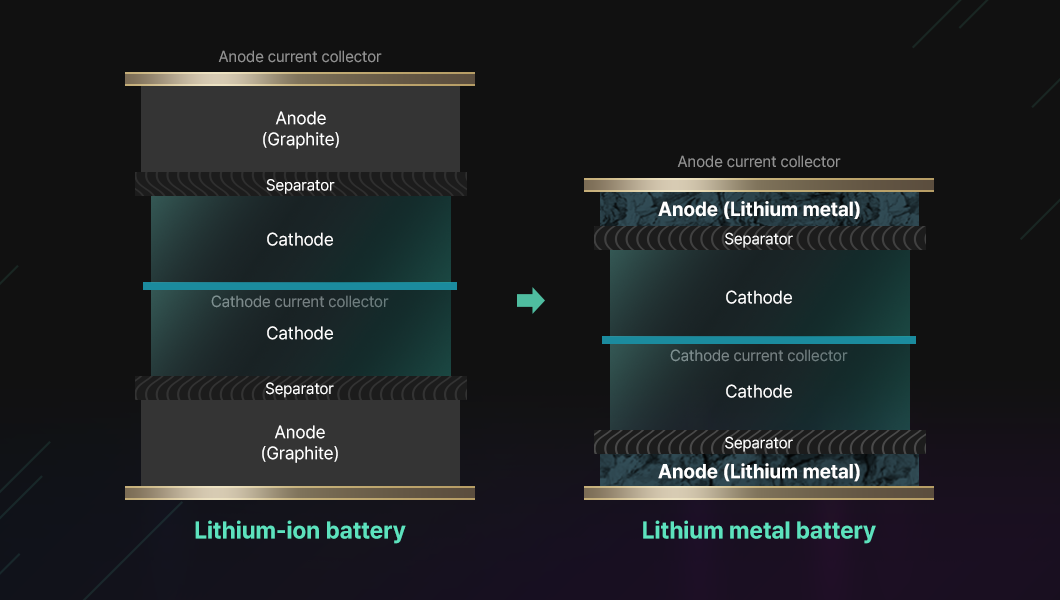

A lithium metal battery uses lithium metal for the anode, metal oxide-based materials (like the ones in lithium-ion batteries) for the cathode, and a liquid electrolyte. The lithium metal anode material is used for various next-generation batteries. A battery that has a cathode with a sulfur-carbon composite is a lithium-sulfur battery, and one containing oxygen as a cathode material is a lithium-air battery.

To trace the origins of lithium metal batteries, we need to go back to the 1970s. Professor Stanley Whittingham, a Nobel laureate in chemistry, developed a battery using titanium disulfide for the cathode and lithium metal for the anode. However, it was not commercialized due to safety concerns. Later, the Canadian company Moli Energy initiated commercialization efforts for lithium metal batteries. In 1988, Moli Energy developed “Molicel,” a rechargeable battery, using molybdenum disulfide for the cathode and lithium metal for the anode. Molicel was installed in mobile phones released by the Japanese telecom company NTT. Nevertheless, lithium-ion batteries, which were safer than the initial lithium metal batteries, eventually dominated the market.

Key Advantages of Lithium Metal Batteries

So, what makes lithium metal batteries one of the leading next-generation batteries?

First, lithium metal batteries can achieve higher energy density than lithium-ion batteries that use graphite for the anode. Graphite has a relatively low theoretical capacity of 372mAh/g. In contrast, lithium metal has a theoretical capacity of 3,860mAh/g, which is over 10 times higher than that of graphite. Accordingly, lithium metal batteries can store significantly more energy for the same weight.

*Theoretical capacity: The maximum content of lithium ions that can be stored in an electrode material within the physical limit

Additionally, lithium metal batteries can reduce battery volume. Although lithium has a relatively large volume per unit mass (with the density of approximately 0.534g/cm³), it offers more than 10 times the capacity of graphite, allowing for a thinner anode. Therefore, the space can be utilized more efficiently, allowing storage of more electrical energy in the same space. This makes lithium metal batteries a suitable option for extending the operation time of battery-mounted devices or as an energy source for systems that consume a lot of power, such as autonomous vehicles.

Third, lithium metal batteries have the potential for faster charging than conventional lithium-ion batteries. In lithium-ion batteries, lithium ions are stored by intercalating into the layered structure of graphite during charging. However, in lithium metal batteries, lithium ions move to the anode and are directly reduced and electrodeposited onto the lithium metal surface, without needing to find spaces within the structure. This, theoretically, allows for faster charging.

Lastly, lithium metal batteries can be manufactured using liquid electrolyte, and therefore can be produced in a similar process with lithium-ion batteries. So, part of lithium-ion battery manufacturing equipment can be repurposed, and the production process can be optimized quickly. LG Energy Solution is focusing on these advantages of lithium metal batteries and is conducting extensive research to bring them to life.

“Dendrite,” the Obstacle to Overcome in Commercializing Lithium Metal Batteries

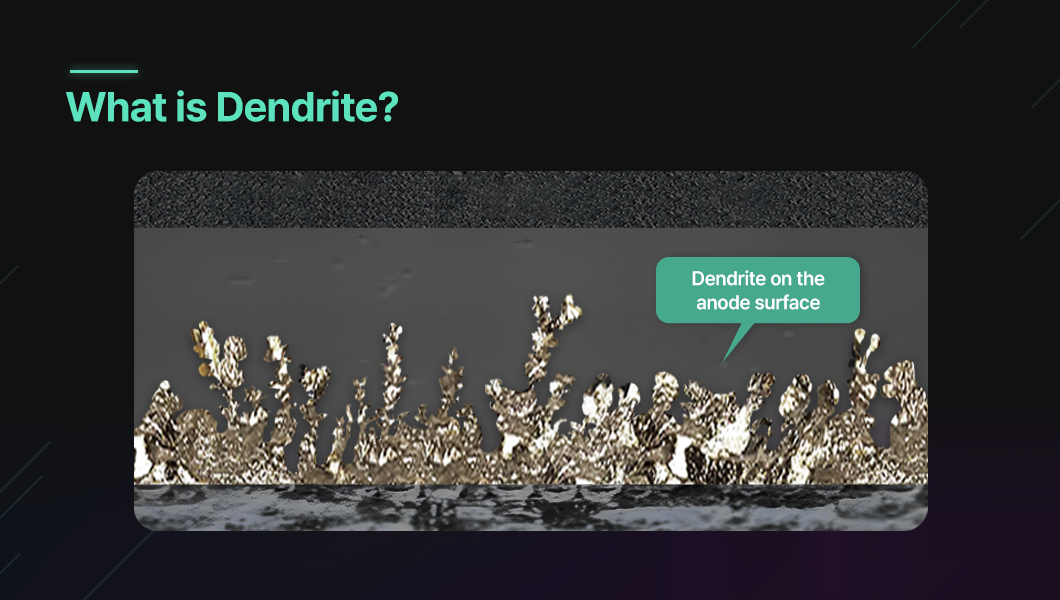

Despite its many advantages, lithium metal batteries face a key challenge for commercialization: dendrites.

Dendrites are tree-like lithium crystals that grow on the anode surface during charging. Their formation is closely related to the characteristics of lithium. When lithium is plated and accumulates on the anode surface, more lithium tends to build on top of the plated lithium metal particles, if there are some already. Then, instead of being plated uniformly across the entire electrode, lithium grows into a tree-like structure.

Dendrites could impact the lifespan and safety of the battery. As dendrites grow, they could damage the separator and extend to the cathode surface. When this happens, the cathode and anode can come into direct contact, causing an internal short circuit. Additionally, dendrites increase the surface area of the lithium electrode, which accelerates reactions with the electrolyte and leads to the corrosion of the lithium metal.

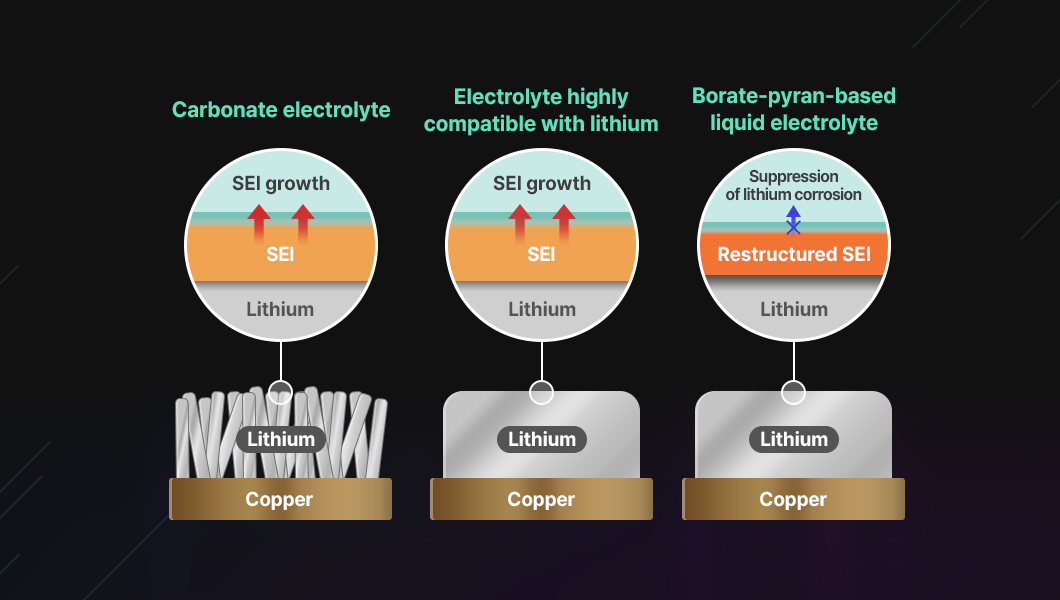

In lithium-ion batteries, a thin film called the Solid Electrolyte Interphase (SEI) forms on the surface of the graphite anode during the formation process. The SEI serves as a protective layer, allowing lithium ions to travel safely and preventing direct contact between the anode surface and the electrolyte. However, an uneven SEI formed due to dendrites compromises this protective layer, leading to reduced charge/discharge efficiency and diminished battery capacity.

LG Energy Solution’s Pursuit to Secure the Ultimate Anode Material: Committed to Developing Lithium Metal Batteries

LG Energy Solution swiftly embarked on research to overcome the challenges of lithium metal batteries and develop a high-performance lithium metal battery with advanced technology.

In 2013, LG Energy Solution began basic experiments as part of its innovative battery project to determine the right candidates for next-generation batteries. The lithium metal battery was selected as one. Requests of automotive manufacturers followed, and the battery was taken seriously from 2021.

As this was a highly difficult project, LG Energy Solution proactively sought diverse perspectives to find good ideas and build research capabilities. In 2021, the company established the Frontier Research Laboratory (FRL) with KAIST to develop source technology of lithium metal batteries, and in 2022, a new project team was formed to advance this research.

What are the unique features of LG Energy Solution’s lithium metal batteries? To maximize the advantage of high energy density of lithium metal batteries, LG Energy Solution is developing a lean electrolyte* system that minimizes the necessary amount of liquid electrolyte. The research team developed a borate-pyran-based electrolyte system in collaboration with KAIST. Their study led to a world-first discovery that restructuring the SEI layer improves stability and reduces electrolyte consumption, marking a step forward in realizing a lean electrolyte system.

*Lean Electrolyte: A system that uses a minimum amount of liquid electrolyte to maximize battery capacity.

This achievement led to outstanding results: Improved charge-discharge efficiency and enhanced energy density, allowing for a driving range of up to 900 km on a single charge. This is a 50% improvement from the approximate 600 km range offered by lithium-ion batteries currently used for high-performance electric vehicles. Also, the battery demonstrated stability in lifespan, supporting over 400 recharge cycles.

What is LG Energy Solution’s Lithium Metal Battery Roadmap?

LG Energy Solution’s lithium metal battery technology is remarkable in that it has overcome the limitations of lithium metal batteries and moved closer to commercialization. The company is committed to continuous research to develop and commercialize safer and more efficient lithium metal batteries. The battery maker plans first to launch batteries for low-capacity systems by the end of 2027, and then to include high-capacity system products on its list as well.

We’ve explored lithium metal batteries among next-generation batteries. As the demand for high-performance batteries continues to grow, the battery industry remains focused on advancing lithium metal battery research. LG Energy Solution is also accelerating efforts to secure competitive technologies for commercializing lithium metal batteries. Stay tuned for the next feature on next-generation batteries, and thank you for your interest!