Climate change has led many countries to pledge to go carbon neutral and decide to adopt green energy. As a result, the importance of EVs increased, which in turn raised the demand for minerals used for manufacturing EV batteries. Battery makers across the world put a lot of effort into securing the elements. Today, we will look at the key raw materials needed for making batteries and battery supply chains.

Q. What are common battery raw materials?

Lithium-ion batteries, the leading product in the battery market, comprise the cathode, anode, separator, and electrolyte. Among them, the cathode determines battery performance and contains the largest amount of raw materials. Common cathode materials include lithium, nickel, cobalt, and manganese.

Lithium is an essential element for batteries and determines energy density. Lithium batteries mostly contain lithium hydroxide or lithium carbonate, with the former preferred for high-capacity EV batteries and the latter used for electronic devices such as smartphones and laptops. As the battery market increased, it began pushing up lithium prices and gave the metal the nickname “white oil.”

Nickel is also related to energy density. When the nickel portion rises, the energy density also goes up. Since it can improve battery capacity and output while reducing the portion of expensive cobalt, nickel’s importance is only growing. The battery industry is intent on developing “high-nickel (High-Ni)” battery, a battery with higher nickel content.

Cobalt prevents corrosion and improves the stability of the cathode. The metal is rare because it is mostly mined as byproduct of copper or nickel.

Last but not least, manganese raises battery stability. Currently, only a little amount is required for battery manufacturing, but the demand is expected to surge when “high manganese (High-Mn)” that contains manganese instead of cobalt becomes popular.

Q. Which countries have critical battery minerals?

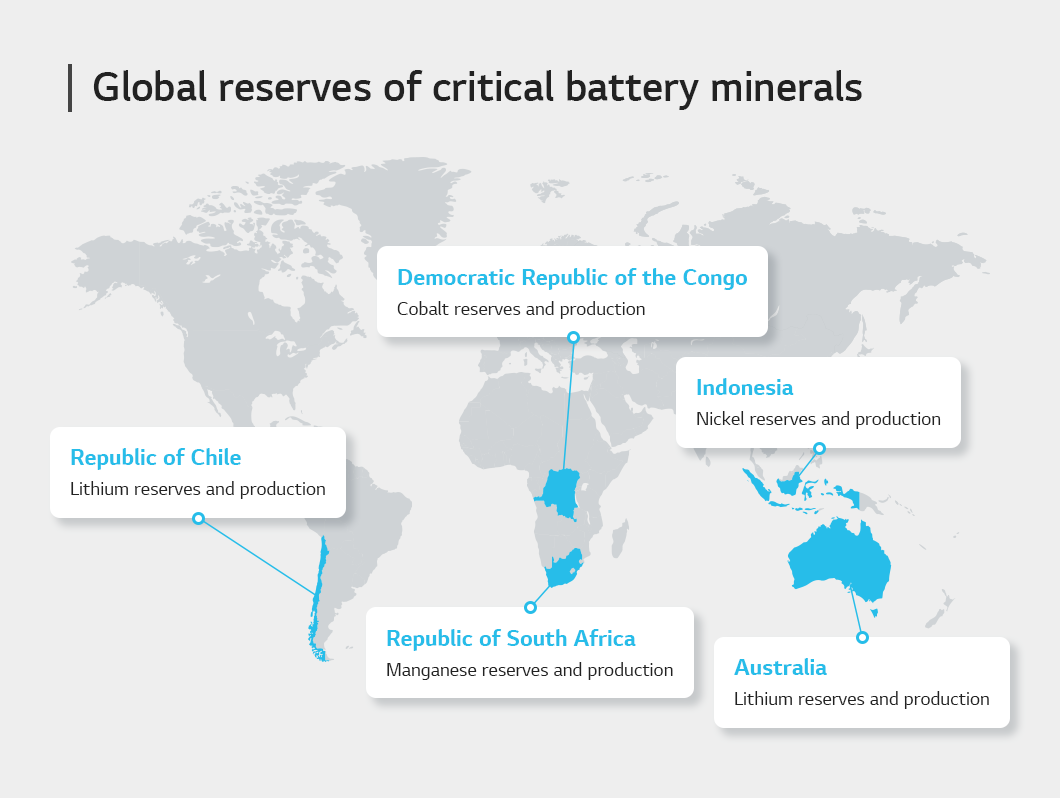

While demand for batteries skyrocketed, only a few countries have key raw materials. Where are these minerals located?

Global leaders of lithium reserves include Chile, Australia, Argentina, China, and the U.S., with the largest shares found in Latin America, such as Uyuni in Bolivia, Hombre Muerto in Argentina, and the Atacama Desert of Chile. Australia, Chile, and China alone hold about 90% of the total lithium production.

Nickel, for which demand is growing currently, is normally found in Indonesia, Australia, and Brazil. Among them, Indonesia has the largest nickel reserve and also is the largest nickel producer.

The highly rare cobalt is produced mostly in the Democratic Republic of the Congo, Australia, Indonesia, and Cuba, with the DRC accounting for more than 70% of the global production.

Last but not least, manganese is known to be deposited mostly in the Republic of South Africa, Australia, Brazil, and Ukraine. Producers of manganese include the Republic of South Africa, Gabon, China, and Australia.

Q. What is South Korea doing to secure critical battery materials?

Only a small number of countries have critical battery minerals and they dominate production. Accordingly, South Korea has to import precursor,* a chemical compound that consists of key materials such as nickel, cobalt, and manganese. South Korea imports most of such compounds including precursors from China with some other raw materials being supplied from other countries.

*Precursor: An ingredient of the cathode, the precursor is in the stage before it becomes the cathode.

South Korean battery makers are developing homegrown precursor production technology to reduce their dependence on imports. As they do so, domestic production of nickel sulfate and cobalt sulfate, compounds needed for making precursors, is increasing. They are also expanding supply chains for minerals cooperating with foreign companies.

The government is offering policy support for the battery makers to secure raw materials. Specific plans include cutting import dependence on certain countries to a 50% level by 2030 and raising the recycling rate up to 20%.

Q. What is LG Energy Solution doing to secure supply chains for critical minerals?

LG Energy Solution is establishing systematic networks with its global partners to build stronger and stable supply chains in the right way.

The battery manufacturer signed a spodumene* supply and equity investment agreement with Green Technology Metals. Accordingly, the Australian company will supply LG Energy Solution with 25% of its total spodumene production for the coming 5 years. Syrah Resources, another Australian company, will deliver 2,000 tons of natural graphite from 2025 and Queensland Pacific Metals, an Australian business specialized in battery metal refining, will supply 7,000 tons of nickel and 700 tons of cobalt, both produced in environmentally-friendly ways, every year for a decade.

*Spodumene: A mineral from which lithium hydroxide can be extracted

LG Energy Solution is also partnering with North American companies. First, it established supply chains for key minerals with Electra and Snow Lake Lithium, both of which are Canadian mineral companies. The battery maker began receiving 7,000 tons of cobalt sulfate from Electra in accordance with the 3-year deal that started from 2023, and will be provided with 200,000 tons of lithium hydroxide from Snow Lake for 10 years. Also, it entered a deal with Compass Minerals for the supply of 40% of lithium hydroxide or lithium carbonate the US lithium provider produces for 7 years from 2025.

The battery maker established key mineral supply chains also in Europe. Under its offtake agreement with Vulcan Energy, a lithium producer in Germany, LG Energy Solution will be supplied with 45,000 tons of lithium hydroxide for 5 years from 2026. It has other partners in China, Indonesia, and Chile as well, and they will also provide key minerals.

We have covered the types of critical battery minerals and global supply chains. In so doing, we learned that LG Energy Solution is preemptively securing key minerals. The battery maker is committed to continuing technology innovation by obtaining high-quality raw materials. You can look forward to its bold moves to make a better world with batteries.