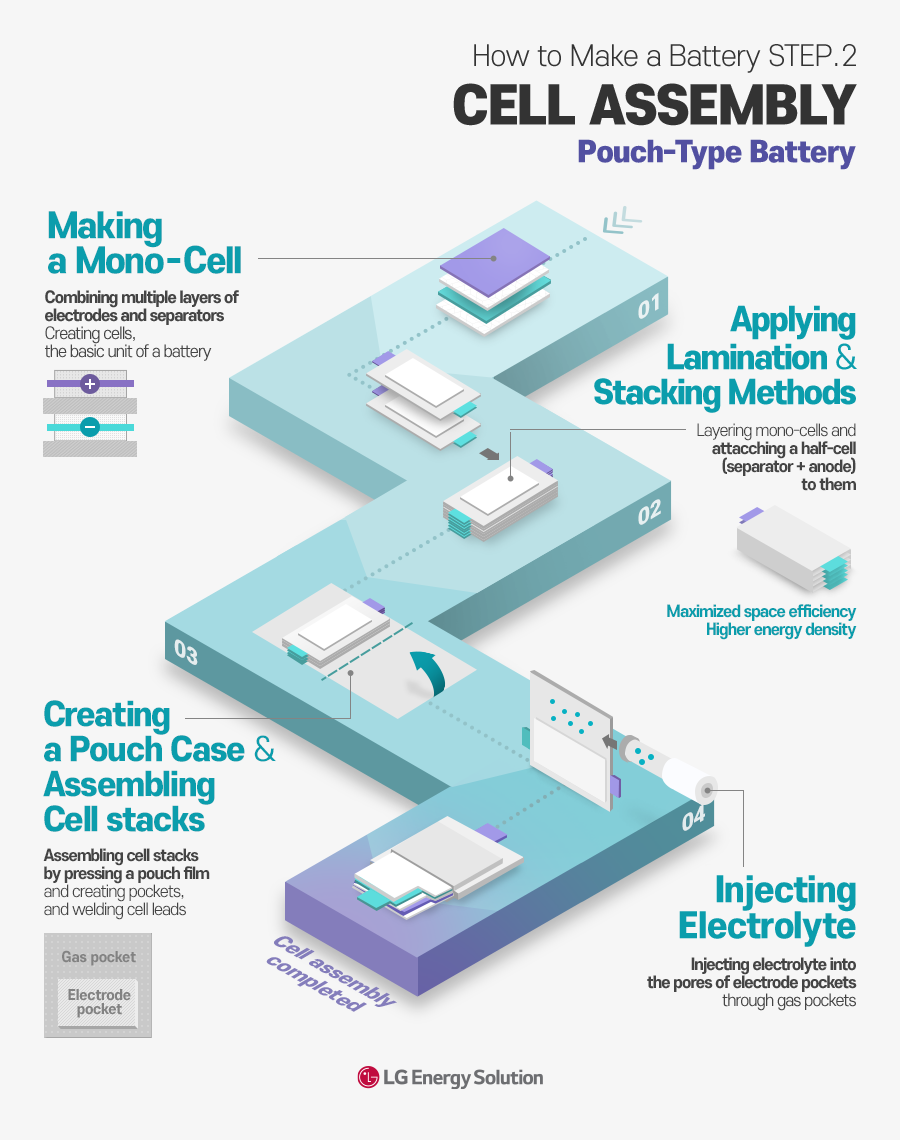

In the second step of battery manufacturing, “cell assembly,” the shape of batteries is decided. The orders and methods employed for manufacturing depend on the shape of the battery. How are pouch-type batteries, the light and highly energy-dense ones among different battery types, assembled? Let’s find out with an infographic.

Making a Mono-cell

To place the battery materials into the pouch case pocket, a mono-cell is first required. The mono-cell is the basic unit cell of a battery, consisting of an electrode and two separators. It features a stacked structure in the form of “separator–central electrode–separator–outer electrode.

Lamination & Stacking

The mono-cell incorporates lamination & stacking, a proprietary technology developed by LG Energy Solution. This method maximizes space efficiency within the battery case by stacking battery materials seamlessly while enhancing both energy density and safety. After lamination, which aligns and bonds the cathode, anode, and separator, mono-cells are repeatedly stacked through stacking. When half-cells—each consisting of two separators and an anode—are stacked, they form a cell stack, in which the cathode and anode are alternately layered with separators in between.

Making a Pouch Case and Cell Stack Assembly

In the lamination & stacking method, cell stacks are formed by layering mono-cells. Once the cell stack is complete, leads are welded onto it. Next, the pouch film is compressed, and the cell stack is inserted and assembled. During this process, two pockets are formed: the electrode pocket, where the cell stack is placed, and the gas pocket, which stores gas. Once the cell stack is inserted, both sides and the bottom are sealed using a sealing tool that applies heat and pressure.

Electrolyte Injection

Electrolyte is injected through the gas pocket, reaching the pores of the electrode pocket. Once the injection is complete, the filling port is sealed using a sealing tool. After assembly, unwanted gases may collect in the gas pocket. These are later removed during the degassing step in the formation process.

We have caught a glimpse of the assembly process of pouch-type batteries!

LG Energy Solution is enhancing the productivity and quality of pouch-type batteries with the differentiated lamination and stacking method.