The exterior is complete after the assembly process. Now, it is time to give the battery the electrical properties so that it can play the supposed roles. Let’s look at formation, the third step of battery manufacturing to find out how it’s done.

What is Formation?

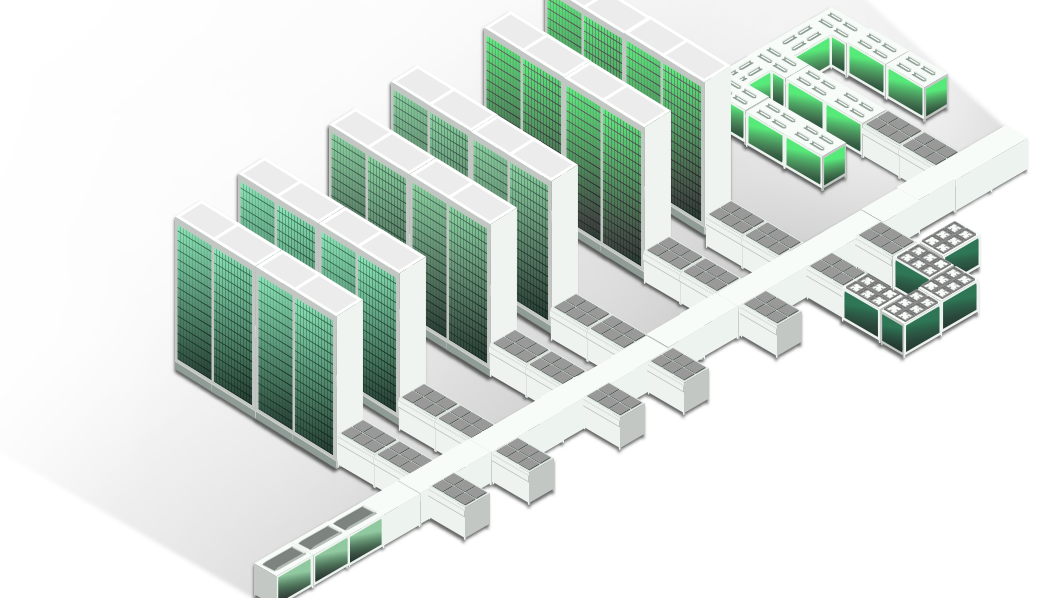

After assembly, the battery is activated with electric energy, and its safety is checked in the next step: formation. Most of the process is automated and consists of repeated aging, charging, and discharging.

* The formation process may differ by manufacturer.

Aging

First, the electrolyte injected in the cell assembly must adequately permeate the battery’s cathode and anode. To facilitate this process, the battery is stored for approximately 1.5 to 3 days. The process of putting the battery at a certain temperature and humidity is called aging. In this process, the electrolyte evenly soaks into the inside of the battery, allowing smooth movement of ions between the cathode and anode of the battery.

SEI Layer

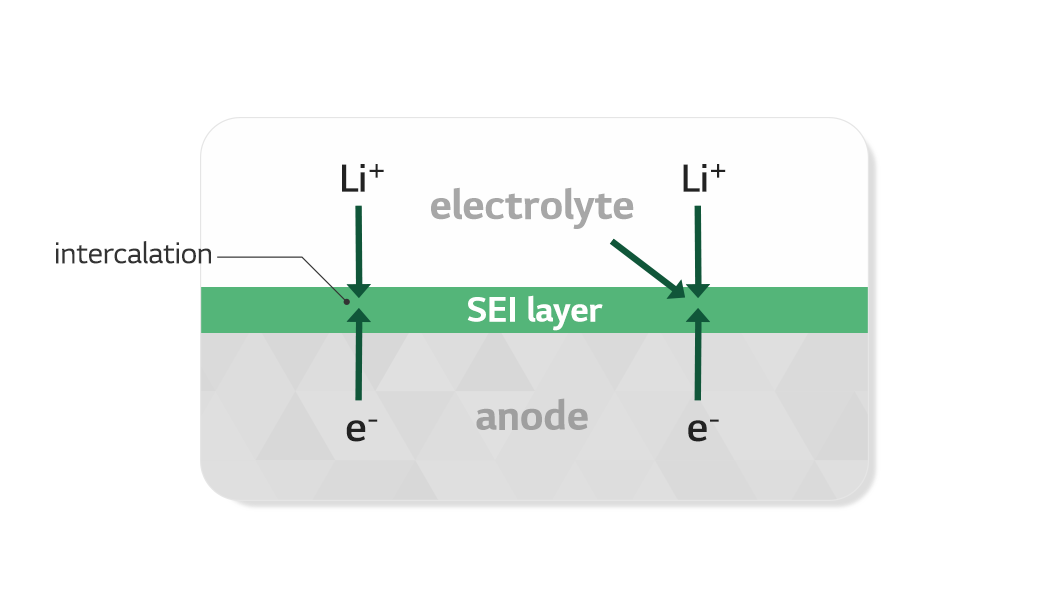

After aging, the battery is charged to a certain level. During the charge, all lithium ions move to the anode, prompting a decomposition of electrolyte and forming a thin layer called SEI, or Solid Electrolyte Interphase, on the surface of the anode. SEI allows transportation of only lithium ions, stopping electrons. It improves battery safety by increasing the internal stability and is a critical element for battery performance and life.

Degassing

The charged battery undergoes secondary aging at a high temperature of 60–70°C. This process further stabilizes the SEI (Solid Electrolyte Interphase) and helps it form a uniform thickness. During aging and charging, gas may accumulate inside the battery. In pouch-type batteries, degassing is performed to remove gas generated by electrolyte side reactions during the initial charging stage.

Testing and Inspection

After degassing, the aging and charging processes are repeated twice. Then, the battery undergoes a charging capacity test and an inspection to identify defective batteries. Through repeated aging and charge-discharge cycles, battery performance, including capacity and resistance, is evaluated. After a designated storage period, an OCV (Open-Circuit Voltage) measurement is performed to detect low-voltage batteries. In the End-of-Line (EOL) process, both performance verification and visual inspections are conducted. Finally, just before shipment, the battery is discharged at 0.1–1C (C-rate), marking the completion of the third stage of battery manufacturing: the formation process.

With the completion of formation, the third process of battery manufacturing, there is only one step left. Next time, we will learn about the pack process, the last part of battery manufacturing.