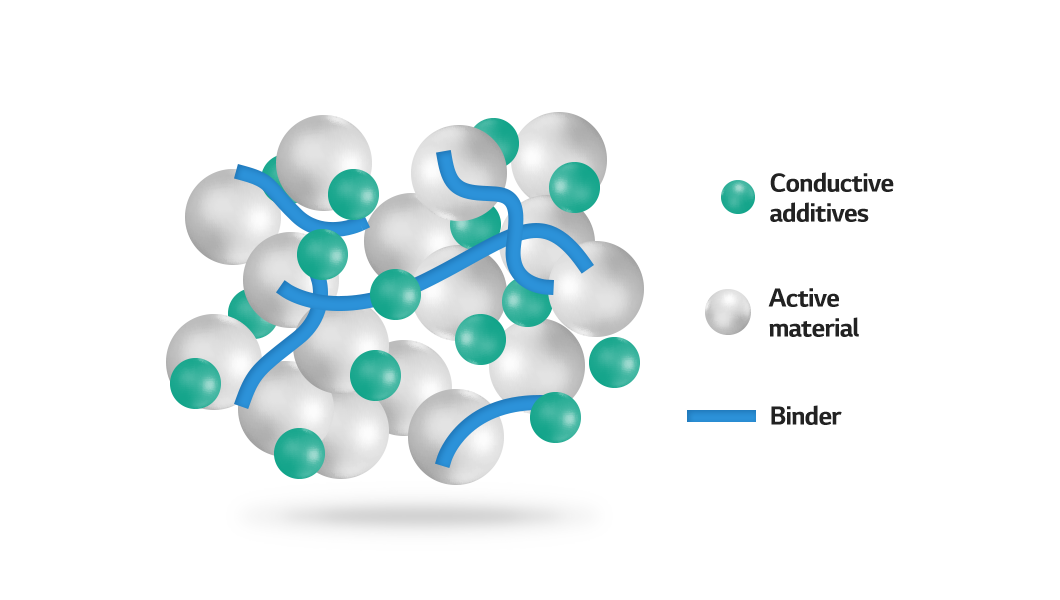

We briefly covered conductive additives in the mixing process which is the first step in battery electrode manufacturing. We learned that conductive additives are added to improve the electrode conductivity when mixing the cathode active materials. This time, we’ll explore what conductive additives are in detail and what types of conductive materials are the most preferred in the battery industry!

What is Conductive Additive?

Conductive additives boost the movement of electrons between cathode and anode active materials.

In other words, they connect active materials to create electric properties. Although only a few of them are added to the electrodes, their role in improving battery performance is critical.

CNTs-based Conductive Additives

Recently, carbon nanotube-based conductive additives are gaining attention for their ability to make a stronger path for electron movement with smaller amounts. Then, what properties do the CNTs-based conductive nanotubes have to enable the connection between active materials even with smaller amounts?

Characteristics of CNT

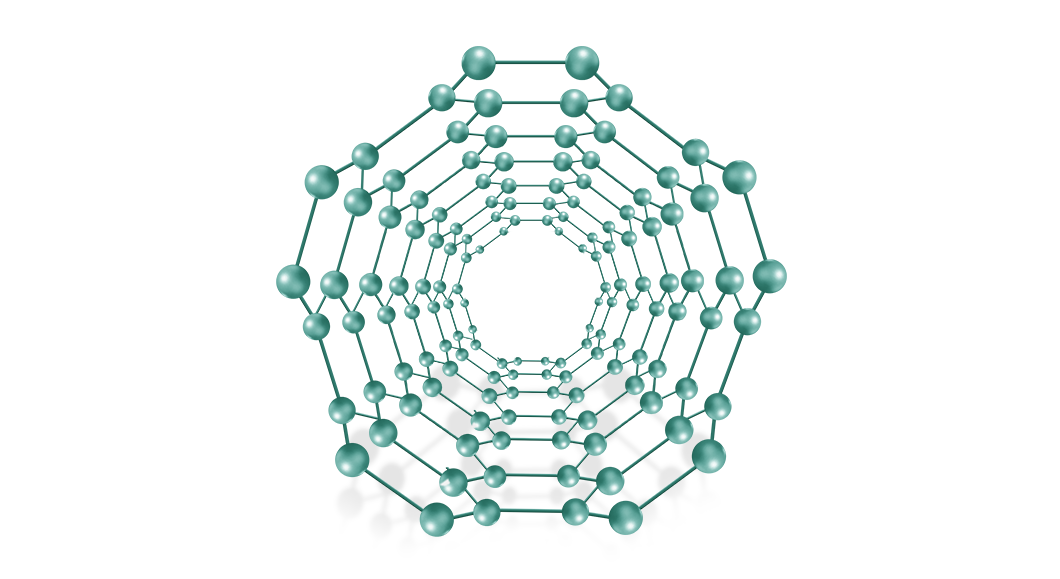

Carbon nanotubes (CNTs) are tubular structures with a diameter of approximately 1 nanometer, formed by rolling up graphene layers, hexagonal networks of six carbon atoms arranged in a horizontal plane. As elongated linear conductors, CNTs have a diameter only one hundred-thousandth the width of a human hair, yet they are about 100 times stronger than steel. Additionally, they possess a high level of electrical conductivity comparable to that of copper.

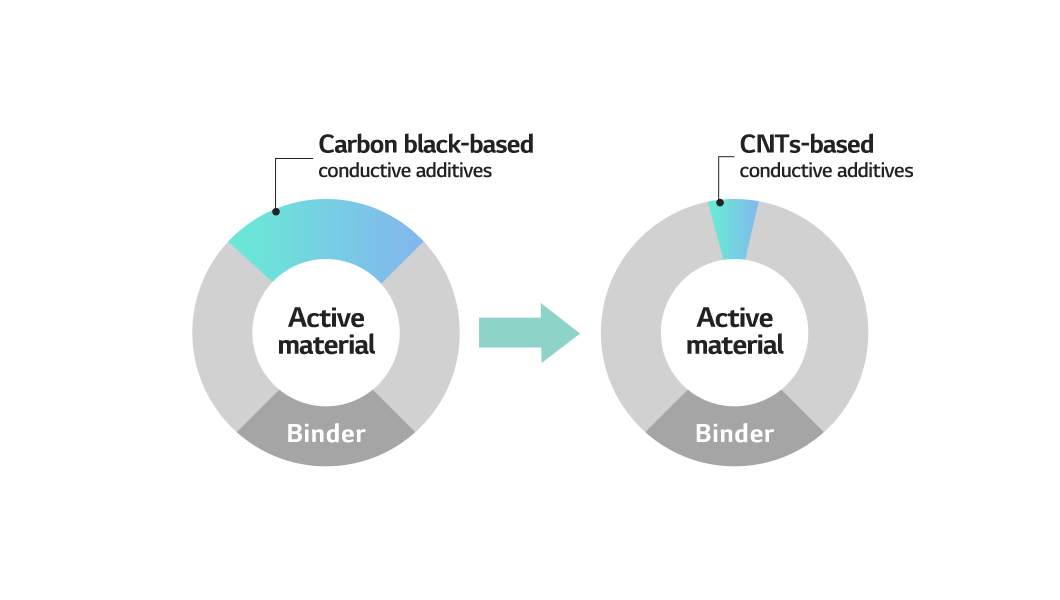

In addition, CNTs-based conductive additives can cut the necessary amount of conductive additives in cathode to one-fifth of its most widely used counterpart, carbon black. That much is enough for producing the same performance as carbon black-based additives due to their high conductivity, meaning higher price competitiveness. Also, the saved space can be used for adding more active materials to raise energy density.

Utilization of CNT

When CNT conductive additives are used in anodes, they provide distinct benefits. Particularly, when CNT conductive additives are added to a silicon-containing anode active material, a strong conductive network is maintained despite the significant expansion and contraction of silicon, leading to a substantial improvement in cell lifespan. Additionally, the high-capacity silicon active material allows for a significant reduction in electrode thickness compared to conventional graphite, making it highly advantageous for fast charging. In other words, it enhances battery lifespan and shortens charging time.

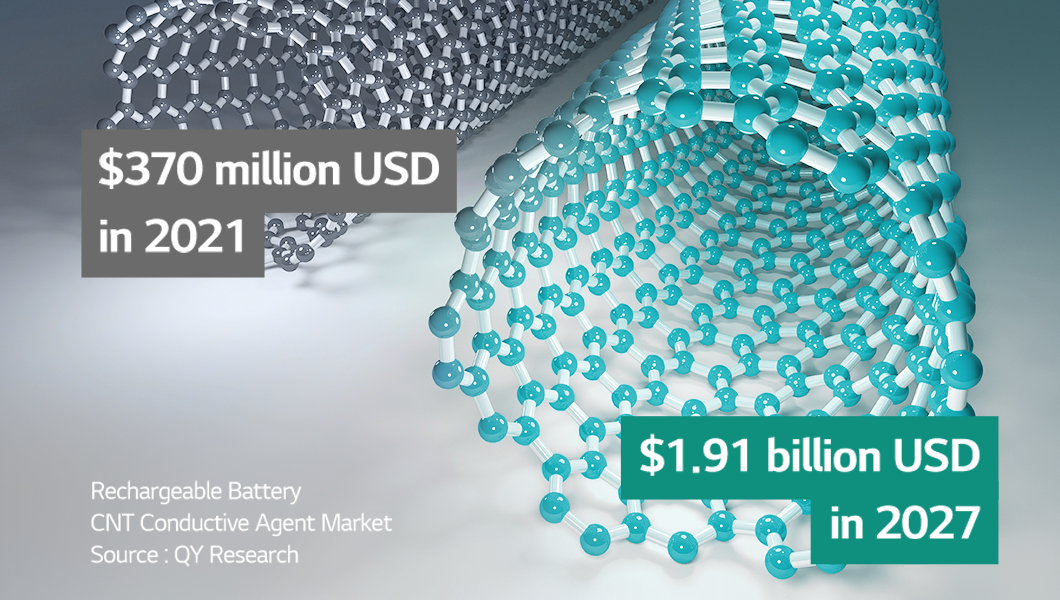

These benefits are expected to propel the growth of the CNTs-based conductive additives market from $370 million USD in 2021 to $1.91 billion USD in 2027. We can look forward to what other benefits they will bring to batteries!