Nowadays, it is common to see electric vehicles driving all around us. You may not own an electric vehicle (EV) yourself, but you would be familiar with the term EV, which stands for an electric vehicle. Literally, EVs are powered by electricity. So to utilize electric energy, they inevitably have batteries installed.

EVs can be further classified into Hybrid Electric Vehicle (HEV), Plug-in Hybrid Electric Vehicle (PHEV), and Battery Electric Vehicle (BEV), depending on the role played by the battery.

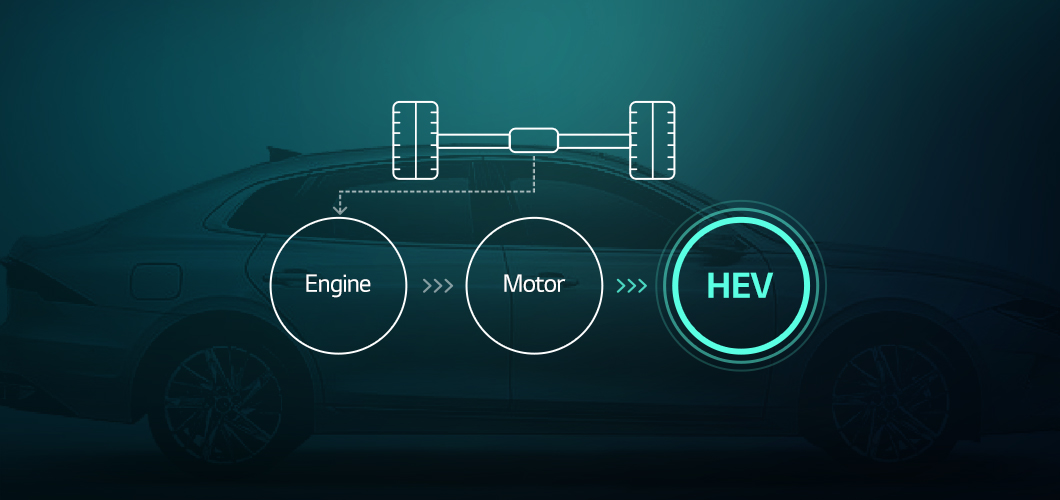

HEV(Hybrid Electric Vehicle)

The battery in HEVs with excellent durability and performance supports the engine. The electric motor increases the output by adding power to the engine when driving. HEVs use batteries with high output, such as nickel-hydrogen or NCA (nickel/cobalt/aluminum) batteries. These batteries are mainly charged through regenerative braking. In other words, when you apply the brakes to decelerate when driving, kinetic energy is converted to electrical energy to charge the battery.

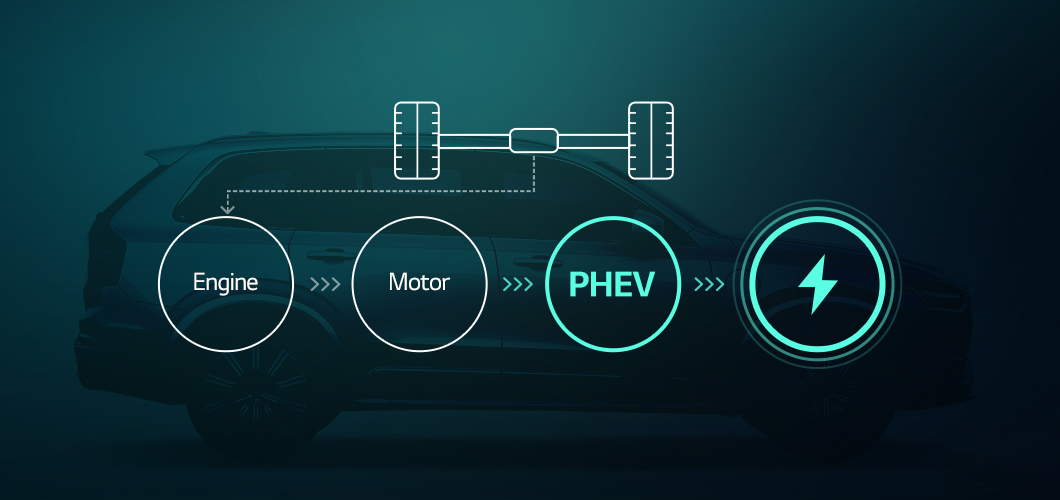

PHEV(Plug-in Hybrid Electric Vehicle)

PHEVs are equipped with batteries that are approximately 4 to 10 times larger than those in HEVs. The lithium-ion battery serves as the vehicle’s primary power source. The engine is used only when all electric energy has been depleted, while under normal driving conditions, only the electric motor operates. Because of this, a higher-capacity battery is required. Since the battery has a large capacity, it can be charged through regenerative braking, but the primary charging method involves connecting to an external power source, such as plugging into a charger. In other words, the most distinctive feature of PHEVs is their use of external power for charging.

BEV(Battery Electric Vehicle)

BEV runs purely on batteries, without an engine, making it a true electric vehicle. BEVs require a large-capacity battery with high energy density and output. In general, BEVs mainly use batteries over 60Ah. For higher energy density, NCM (nickel, cobalt, manganese) or LMO (lithium manganese oxide) could be used for the cathode. LG Energy Solution studies and develops pouch-type battery cells to optimize vehicle design while offering high capacity and high output.

As BEV batteries’ range and charging time improve gradually with battery technologies, BEVs can be classified into different generations. First-generation BEVs were able to charge 80% in one hour and run 200 km, while the latest third-generation BEVs can charge 80% in less than 30 minutes and can run more than 500 km.

Even now, various studies, including those on silicon anode materials, are being conducted to cut the charging speed of BEVs further. As battery technology advances day by day, technological breakthroughs will soon overcome driving range and charging time concerns, making EVs a significant part of our lives.