When you study nutrition facts label on a multivitamin, you can see many mineral names. They include iron, zinc, chromium, copper, and manganese. Among the essential elements for human body, we will investigate manganese that is also in charge of safety in batteries.

The name comes from the Latin magnes for “magnet,” since pyrolusite, the most common manganese mineral, has magnetic properties. (However, despite its name, manganese is not magnetic.) And it has come to be called “manganese” according to the International Union of Pure and Applied Chemistry.

Manganese has the atomic number of 25 with the symbol Mn and mass 54.938. The element’s melting point is 1,247℃ and density 7.2. Belonging to the Group 7 of the periodic table, the silvery metal is hard but brittle. It is so highly responsive that it ignites when in powder form while oxidizing slowly when in the form of mass in air. Also, it produces hydrogen in contact with water.

Manganese is the third most abundant metal in Earth’s crust. It is found in the form of pyrolusite (manganese dioxide, MnO₂) in many areas and has been used as a natural pigment since the Stone Age, about 20,000 to 30,000 years ago. In addition, the element is essential to all life because it helps enzymes necessary for vital activities perform well. In humans, manganese is involved in various body activities, producing blood-clotting factors and controlling metabolism.

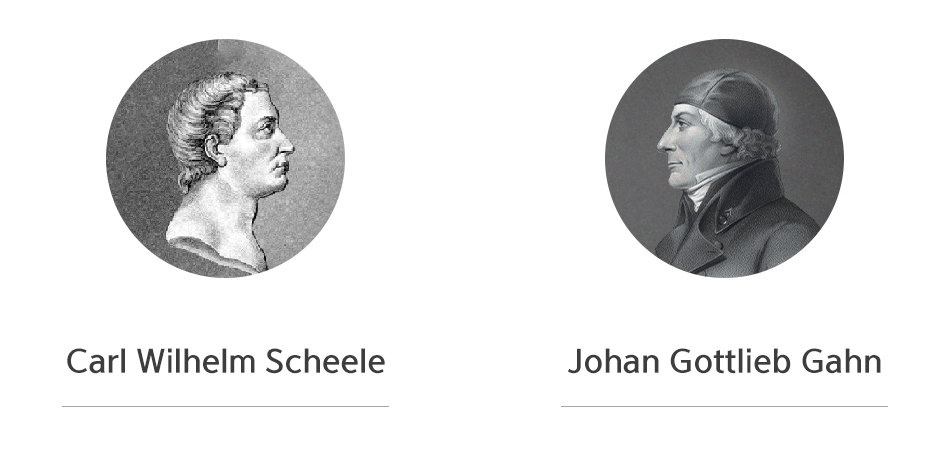

In the mid-1700s, many chemists assumed that pyrolusite would contain a new element that had never been found separated from it. Swedish chemist Carl Wilhelm Scheele (1742-1786) acquired hydrogen chloride (HCl) by mixing salt (NaCl) with sulfuric acid (H2SO4) and then combined the resulting chlorine with the pyrolusite, successfully isolating chlorine for the first time ever in 1774. In doing so, he noticed a new element was present in the pyrolusite. His fellow Johan Gottlieb Gahn (1745-1818), also a Swedish chemist, soon isolated an impure sample of manganese metal (Mn) by heating pyrolusite with charcoal (carbon) and removing oxygen from it. High purity (99.99%) manganese was obtained only about 160 years later in the 1930s through electrolysis of Mn2+ solution.

Since it was discovered that manganese imparts strength to iron in the early 1800s, manganese has been an important ingredient for metal alloy. In 1866, Leclanché cell that uses MnO2 as a cathode material was invented. Then in 1912, manganese phosphating, a type of coating with special benefits of increased corrosion resistance and wear protection when applied to steel, was invented and has been widely adopted in manufacturing car parts.

The recent growth in demand for electric vehicles gave a rise to demand for medium- and large-sized rechargeable batteries. And the most common cathode material for those batteries is NCM (nickel, cobalt, and manganese). Initially, the ratio of each element in NCM was 1:1:1. But recently, NCMA, a safer cathode material that has a higher portion of nickel and contains aluminum was developed. As such, energy density has been raised with additional nickel and price stability is improved by reducing the portion of costly cobalt.

In these cathode materials, manganese takes an important part of raising the stability.

We have covered manganese, a mineral that is crucial for both our body and battery. Next time, we will explore maybe an even more important material for the cathode material of the rechargeable batteries, nickel.