Battery packs are normally completed by assembling numerous battery cells into modules and then connecting those modules together.

But what happens when the module step is eliminated? The space previously occupied by module components disappears, and battery cells fill that space, enabling higher energy density. LG Energy Solution developed Cell-to-Pack (CTP) technology to realize this idea, marking another step forward in innovation.

The Making Every Possibility series introduces the people behind such innovations. In this episode, we meet Jae-chul Lee, who works on advanced processes in the Pack Product Technology Team.

Q. Could you introduce yourself and explain the process?

Hi! I am Jae-chul Lee, and I work on advanced processes in the Pack Product Technology Team. The key technology of LG Energy Solution that I will introduce today is CTP.

CTP stands for Cell-to-Pack. Typically, battery packs progress from cell to module and then from module to pack. But CTP removes the intermediate module step and assembles the cells directly into the pack.

Q. What is the biggest difference from conventional technologies?

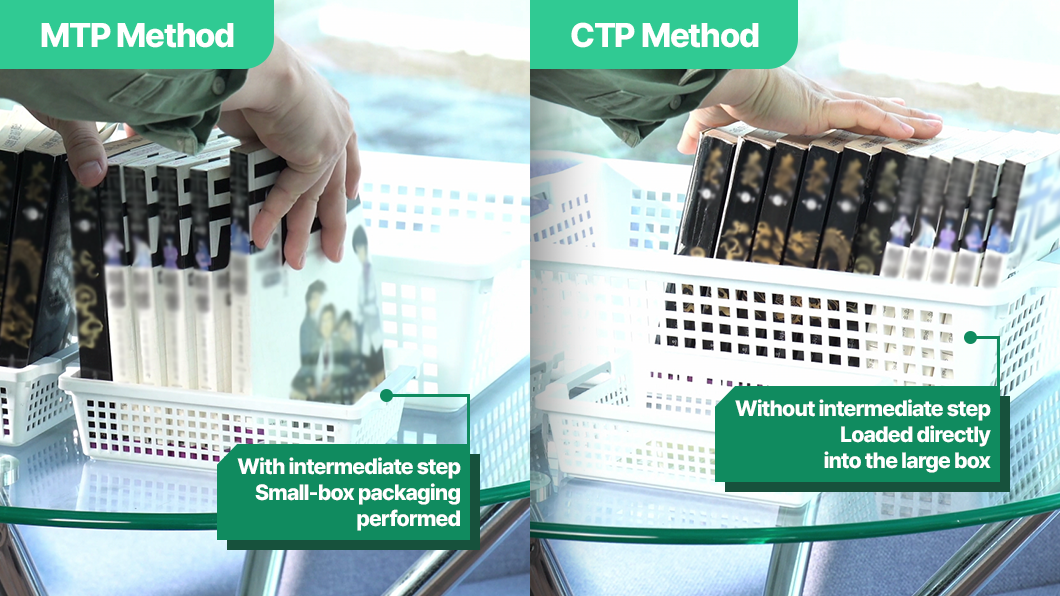

The biggest difference lies in the manufacturing process. Conventional Module-to-Pack (MTP) technology inserts the cells into a module frame, secures them, and then installs the completed modules into the pack. CTP, on the other hand, stacks the cells one by one and places them straight into the pack.

*View (Infographics #8) How to Make a Battery STEP. 4 – Pack Process

Let me use an analogy with books to explain CTP easily. Imagine the books are cells, the small box is a module, and the large box is a pack. MTP wraps multiple books, places them into the small box, and then stores the small box in the large box. When you skip the intermediate wrapping step and stack the books directly into the large box, that is essentially CTP.

Q. What are the advantages of stacking cells without using a module case?

As the module components are removed, space efficiency improves by allowing more cells to be stacked in the available space. While MTP has a space utilization rate of about 40–50%, CTP increases this to 65–72%, resulting in substantially higher energy density.

Q. What was the most pressing challenge in commercializing CTP?

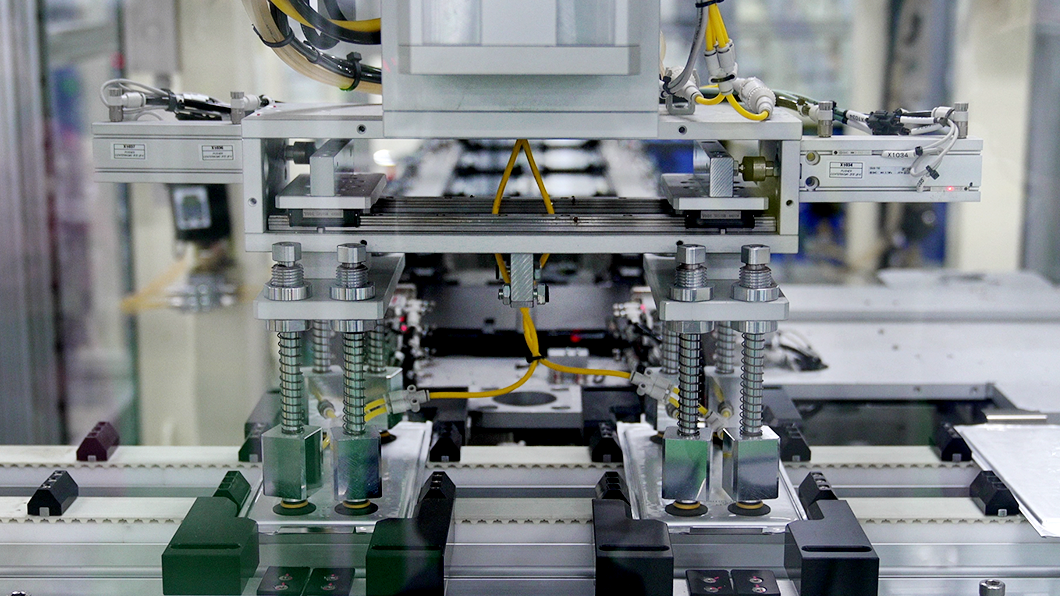

In the CTP structure, where the intermediate module step is eliminated, the biggest challenge was securing the cells stably and maintaining precise dimensions to ensure the designed size and arrangement.

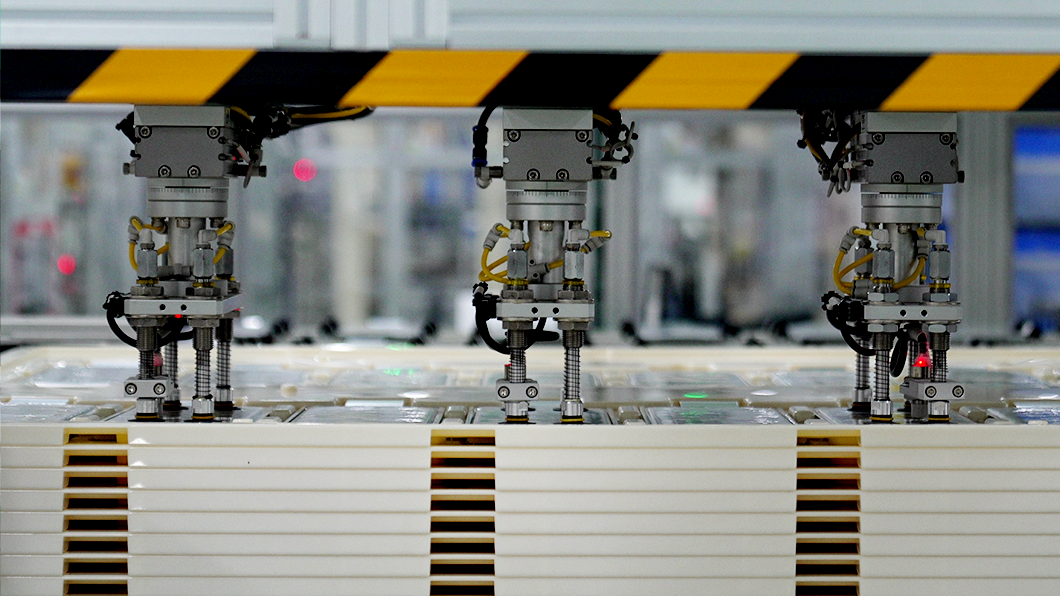

We needed to meet the exact size and shape required for the entire pack by keeping the spacing between cells and their form uniform. To achieve this, LG Energy Solution stabilized the cell block form by applying pressure1 to its sides and developed the Cell Unit Loading process2, which uses upper-side vacuum suction to automatically load the cells. Without these technologies, commercializing pouch-type CTP would have been far more difficult.

Q. What separates LG Energy Solution’s CTP technology from others?

LG Energy Solution applied CTP to pouch-type battery packs for the first time in the world. I believe the company has secured a unique advantage by maximizing energy density in addition to leveraging the structural efficiency of pouch-type battery packs.

In production, the number of CTP process steps has decreased by 26% compared to MTP, and investment costs have dropped by 19.2%. As a result, the production process has been streamlined, and overall manufacturing costs have been lowered.

Q. Can CTP technology be applied to areas beyond electric vehicles?

CTP technology is applicable to a wide range of fields beyond electric vehicles. Researchers are exploring possibilities for applying it to high-capacity, high-output batteries. In particular, extensive studies are underway to adopt CTP for battery projects that require high energy density and strong space efficiency, such as energy storage systems (ESS).

CTP is a truly innovative technology for pouch-type batteries. It is expected to open new possibilities across the battery industry by not only streamlining production processes but also significantly enhancing energy density. LG Energy Solution will continue to develop advanced process technologies, including CTP. If you are interested in learning more about CTP, click the article below!

*View [Battery Pioneer] Innovative Cell-to-Pack Technology that Eliminates Modules

- Vacuum Suction: A technology that pulls and lifts cell blocks using air-pressure differences ↩︎

- Cell Unit Loading: A process that compresses cell blocks and inserts them into the pack housing using a robot ↩︎