LG Energy Solution is making a better world through its battery technologies. In October 2024, the company announced its new vision, “Empower Every Possibility,” outlining a clear direction to lead the future by building an energy circulation ecosystem that goes beyond just manufacturing batteries.

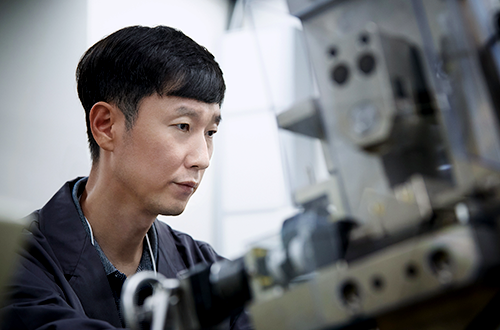

However, battery technologies do not come to life on their own. Envisioning, designing, and implementing technology in the field requires a human touch. And the ones who open the possibilities of an energy circulation ecosystem are none other than the employees of LG Energy Solution. “Making Every Possibility” is an interview series introducing employees who turn possibilities into reality in their respective fields. In this first feature, we meet Ho-seong Son, who works on winding technology in the Cylindrical Assembly Production & Technology Team 1.

Q. Could you introduce yourself?

Hi, I’m Ho-seong Son, and I work on winding technology in the Cylindrical Assembly Production & Technology Team 1.

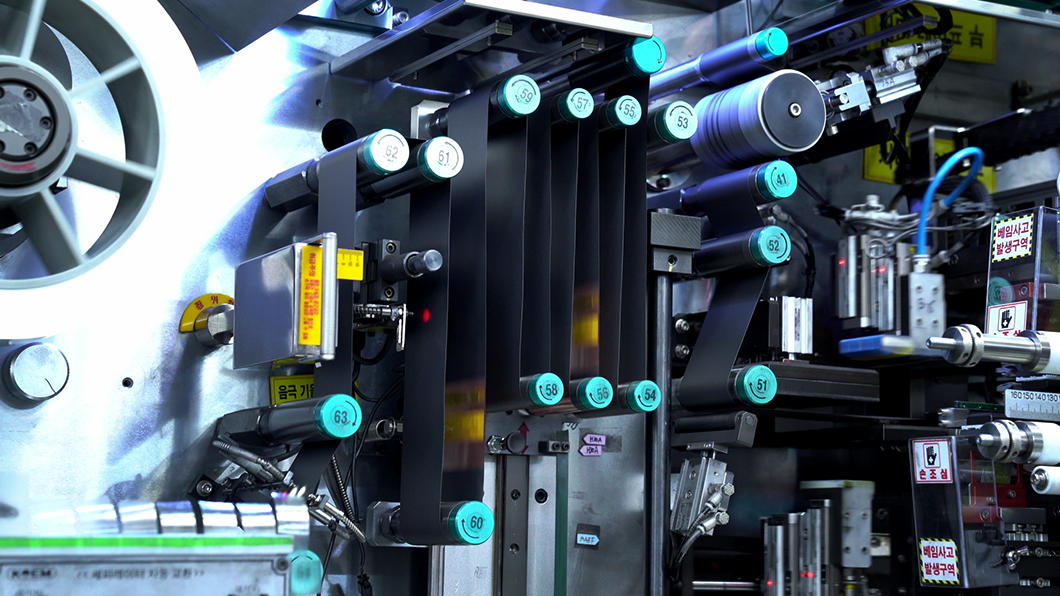

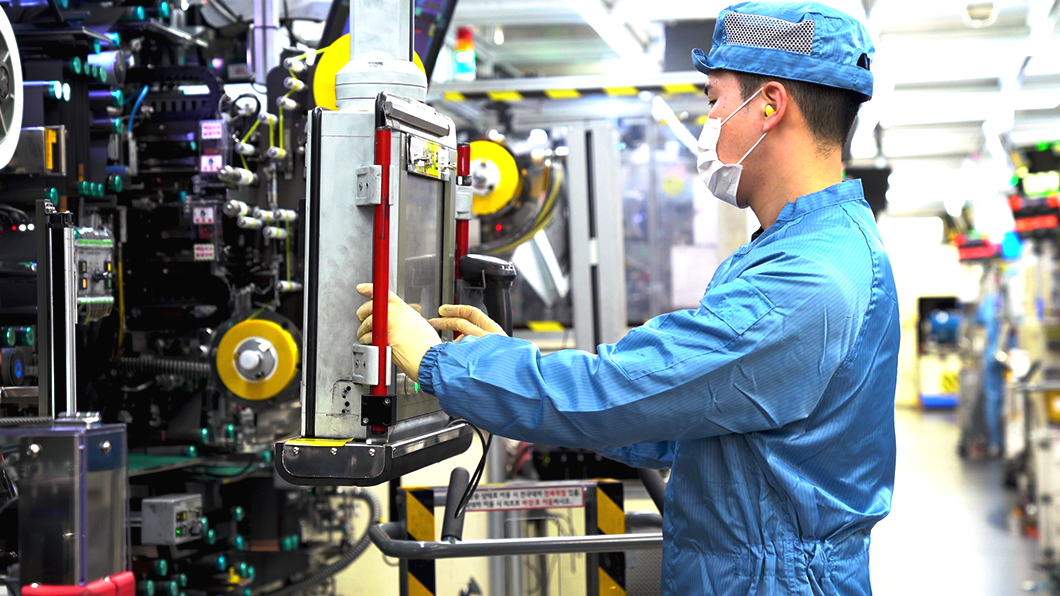

Unlike pouch-type batteries, cylindrical batteries undergo a winding process, where the cathode and anode produced during the electrode stage are wound in a machine called a winder. This is what we refer to as the winding process. In this step, the cathode and anode are fed through the winder while tabs and tape are attached. They are then wound in a dry motor to the required length, resulting in the jelly roll structure.

Q. How are the electrodes rolled into a cylindrical shape, and what are the advantages of the winding process?

It’s easier to understand if you think of a toilet paper roll. The cathode, anode, and two separators are wound together around a mandrel, which functions like the center tube, in a defined order and specification to form the jelly roll. During this process, they are wound to the desired length with uniform spacing between them.

Since the winding process wraps the electrodes by rotating them, it offers faster production than the folding method. This higher productivity also helps reduce manufacturing costs. Thanks to this advantage, more EVs can be produced more quickly in the automotive market.

Q. What are the most important technical factors in the winding process?

There are three major technical factors in the winding process.

The first is sensor and motor control. The cathode, anode, and separators must be wound according to defined specifications, with uniform spacing and accurate alignment. Because the sensor must precisely detect data such as the feed amount of each material and the motor adjusts its speed and movement accordingly, the two units must be controlled with high precision.

The second factor is controlling winding speed and maintaining proper tension. As the name suggests, winding involves rolling the electrodes and separators together. If tension and speed are not kept consistent, the materials can wrinkle or become damaged. Therefore, the cathode, anode, and separators must be fed at appropriate tension and stable speed.

Lastly, misalignment measurement and correction control are necessary. Misalignment measurement refers to a state where the cathode, anode, and separators are not wound properly, and become skewed. When this occurs, the materials are positioned incorrectly, which can affect product quality. Therefore, misalignment control is essential.

Q. What differentiates LG Energy Solution’s winding technology?

LG Energy Solution’s winding process stands out in several ways.

First, the company conducts full inspections using vision1 systems, encoders, and sensors to manage product specifications. The data collected during this process is linked with multiple systems, including production and quality systems, and is monitored in real time. This provides the foundation for delivering the highest-quality products to customers.

Another key differentiator is that the process not only determines pass/fail results through vision inspection, but also feeds the results back directly to the equipment to control the facilities. Such precise battery status inspection helps further improve yield and quality.

Q. How would winding technology evolve in the future?

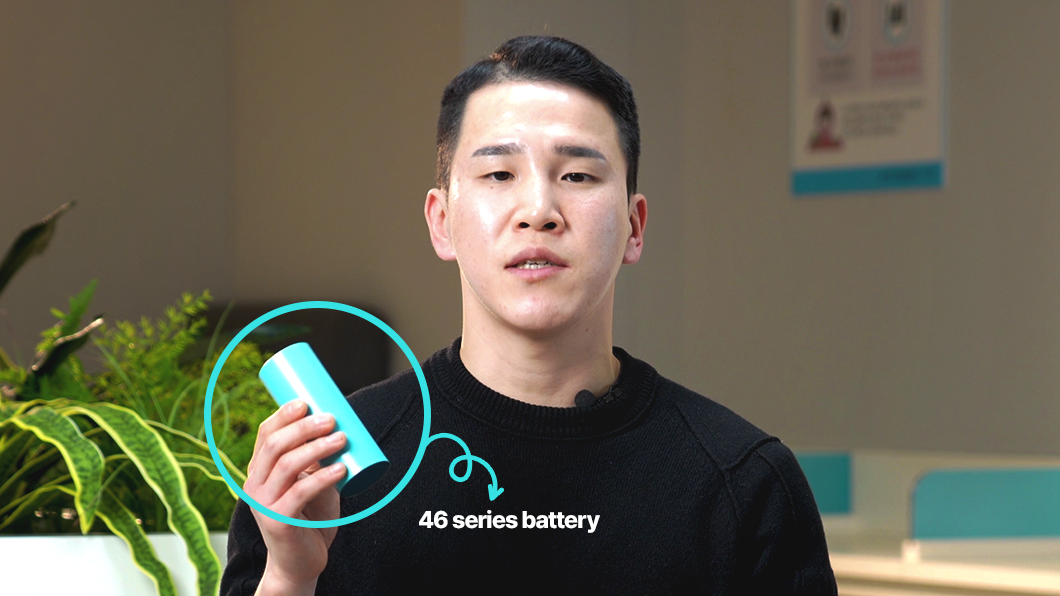

Currently, 46-series cylindrical batteries are gaining significant attention as next-generation batteries. The 46 series has a larger cell diameter than conventional 2170 batteries, which allows it to store more energy and contain more wound electrode layers inside. In addition, while the cathode and anode tabs in 2170 batteries are welded, in 46-series cells, the edges of the electrodes are directly notched to function as tabs. This structure helps reduce resistance and enable higher output performance.

We spoke with Ho-seong Son, who works on winding, a key process in cylindrical battery manufacturing. LG Energy Solution is opening new possibilities for building an energy circulation ecosystem through cylindrical batteries enhanced by advanced winding technology. LG Energy Solution will continue to share stories of employees who are shaping the future.

- Vision: A technology for automatically inspecting the appearance and quality of products using cameras. ↩︎