Batteries are advancing rapidly to become smaller, lighter, and longer-lasting. The industry is focusing on developing high-capacity materials and innovating battery structures to achieve high energy density. Recognizing this trend early, LG Energy Solution has accelerated the development of breakthrough technologies capable of delivering a quantum leap. As part of this effort, the company continues to develop anodeless batteries that eliminate the anode active material entirely, and has solidified its roadmap toward combining them with solid-state batteries.

In this interview, we spoke with Lee Jeong-pil of the Future Technology Center, who is continuing research based on an anodeless battery patent application, and learned about what anodeless batteries are and LG Energy Solution’s differentiated technologies.

What Is an Anodeless Battery?

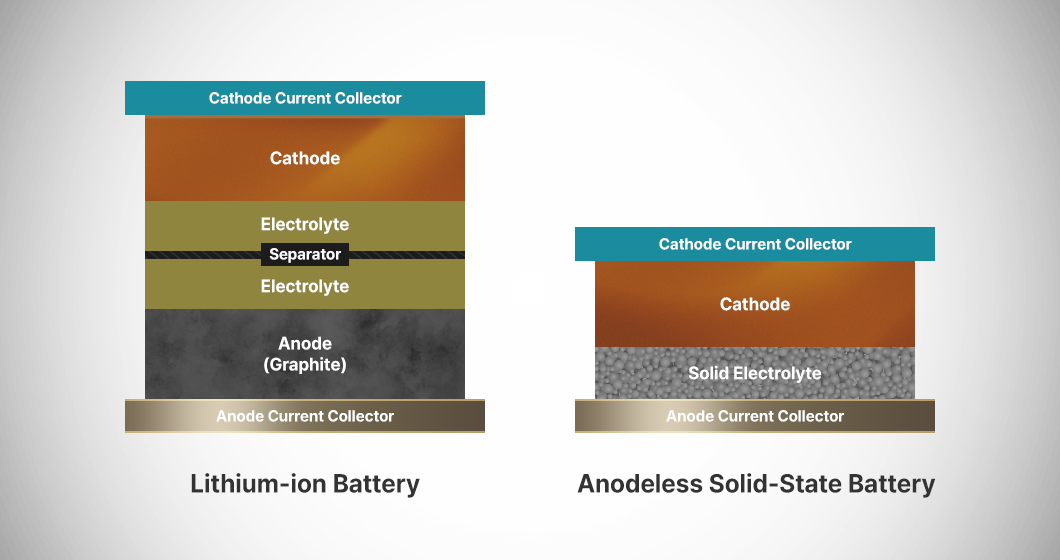

A lithium-ion battery generally consists of four major components: a cathode, an anode, a separator, and an electrolyte. Among them, the anode stores lithium ions from the cathode during charging, and is usually made with anode active materials such as graphite or silicon.

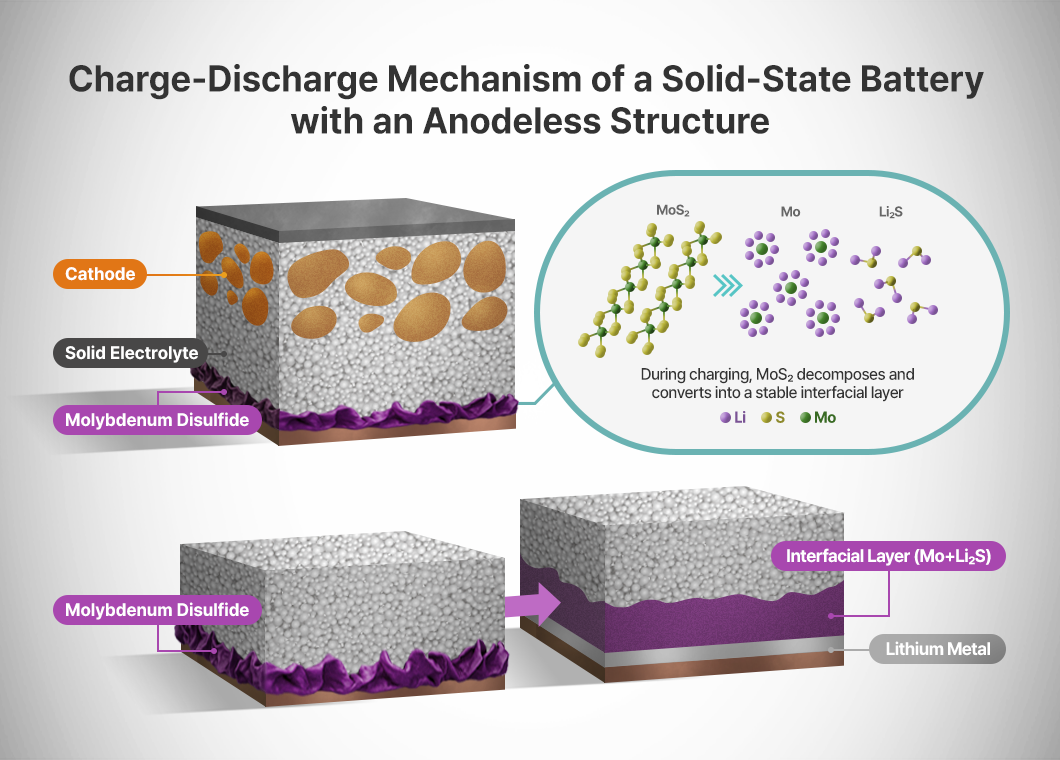

Currently, attention is focused on anodeless technology, which removes the anode active material altogether—going one step beyond the use of conventional anode materials. Anodeless batteries have a structure free of the host space within the anode material that stores lithium. During charging, lithium ions from the cathode combine with electrons and are plated onto the anode current collector in the form of lithium metal. During discharging, the lithium metal releases electrons and is stripped back into lithium ions.

Why Anodeless Batteries Are a Breakthrough Technology

The battery industry has developed high-capacity anode materials, from graphite and silicon to lithium metal, to enhance energy density. Such research has greatly contributed to improving battery performance and driving the step-by-step advancement of next-generation technologies.

Nevertheless, what led researchers to develop anodeless batteries that eliminate anode active materials?

The reason lies in their ability to significantly increase energy density. In conventional batteries, an anode layer of a certain thickness exists even before charging, occupying part of the cell’s volume. In comparison, in anodeless batteries, lithium is plated only during charging, reducing the initial cell thickness and improving space efficiency. This structural advantage allows them to store more lithium within the same volume, providing an advantage in increasing energy density.

Another advantage is lower manufacturing and material costs. Since anodeless batteries do not have anode active materials, the step of forming the anode active material layer can be simplified, streamlining the overall manufacturing process. This reduces material costs and improves process efficiency. In particular, anodes that use lithium metal require a dry-room environment to prevent lithium oxidation, whereas anodeless batteries do not need such facilities.

LG Energy Solution Adds Anodeless Technology to Solid-State Batteries

LG Energy Solution is reinforcing its efforts to secure future growth engines and strengthening its competitiveness in next-generation technologies. As part of these efforts, the company is developing anodeless battery technologies and filing various patent applications. The anodeless technology, developed with the participation of Jeong-pil Lee, features the coating and oxidation of Lithiophilic Materials (LPM) on the anode current collector, as well as the use of a solid electrolyte instead of a liquid one. The patent application for this technology was completed in October 2021 and is protected as LG Energy Solution’s proprietary technology.

We met with Jeong-pil Lee, an anodeless battery technology expert from the Sulfide-based Solid-state Battery 1 PJT at the Future Technology Center, to learn more in detail.

Q. Could you briefly introduce the anodeless battery patent you were involved in?

The key to anodeless batteries lies in their structure, which eliminates anode active materials and allows lithium to be plated and collected. This method dramatically improves energy density. However, if the affinity between the anode current collector and lithium is low, it can lead to the formation of dendrites, branch-like crystals formed when lithium deposits unevenly. These dendrites may penetrate the separator, come into contact with the cathode, and cause short circuits. When this occurs repeatedly, battery performance and safety deteriorate. To address this, LG Energy Solution has applied optimized materials and technologies to ensure uniform lithium growth on the anode current collector during anodeless battery operation.

* View Battery Glossary – Dendrite

Q. What prompted LG Energy Solution to develop anodeless technology, and what differentiates it from other technologies?

LG Energy Solution has been conducting proactive research on a wide range of next-generation battery technologies, including solid-state batteries. It has also developed technologies that go beyond conventional lithium-ion batteries, such as lithium-sulfur, bipolar, and sodium-ion batteries, and anodeless batteries are among them. The technology was worth pursuing, as it enables the design of high-energy-density structures.

Due to their mechanism in which lithium is plated and stripped, anodeless batteries are considered difficult to develop and implement. Factors such as volume change, internal stress, and the location and uniformity of lithium plating that occur during operation affect battery performance and lifespan.

In the early stages of development, the company experimented with liquid electrolyte–based anodeless battery technology. However, issues such as lithium loss, side reactions, and uneven lithium plating remained unresolved, preventing the achievement of the expected performance and lifespan. Across the industry, coating lithiophilic materials on the surface of the current collector was tried as a solution, but this approach was insufficient to overcome the limitations.

LG Energy Solution took it a step further. In addition to coating LPM on the anode current collector, the company applied oxidation treatment and integrated this method into solid-state batteries. Solid-state batteries, which use solid electrolytes, are known to reduce side reactions and offer higher safety, making them a promising solution to addressing the limitations. As a result of these efforts, the company established an environment that enables uniform lithium coating and secured differentiated technological competitiveness.

Q. What are the benefits of applying anodeless technology to solid-state batteries?

Although anodeless technology is theoretically applicable to most types of batteries, research has confirmed that solid-state batteries are the most optimized for minimizing lithium side reactions.

In anodeless batteries, it is crucial that lithium is plated as lithium ions and then stripped back. However, in liquid electrolyte–based anodeless batteries, lithium reacts with the anode during charging, turning into irreversible compounds such as lithium hydroxide or lithium carbonate. Simply put, these reactions impede lithium from being recovered and result in lithium loss. Consequently, implementing anodeless batteries in a liquid electrolyte–based structure can degrade battery performance and lifespan.

In contrast, solid-state batteries use solid electrolytes, making them relatively more stable and capable of minimizing side reactions. This property allows the plating–stripping cycle to be repeated stably and improves performance by reducing lithium loss. Even greater synergy is expected when the structural advantages of anodeless batteries are combined with the stability of solid-state batteries.

Q. What are the respective roles of LPM coating and oxidation, and what is their combined effect?

We combined the two processes of LPM coating and oxidation to induce uniform lithium plating.

LPM coating involves dispersing metals such as silver (Ag), gold (Au), platinum (Pt), zinc (Zn), and magnesium (Mg) onto the surface of the current collector. These lithiophilic materials prevent lithium from concentrating in localized spots and promote uniform plating across the surface.

Not only the coating material but also the coating method significantly affect the uniform dispersion of materials. During the research stage, spin coating proved effective in forming a uniform layer. For future mass production, we plan to apply the most suitable technique among several coating methods, such as slot-die1, comma2, and gravure3.

Additionally, we performed oxidation treatment by adjusting the heat-treatment temperature and duration to control the oxidation level of the current collector. Conventional anode current collectors have low lithium affinity, which reduces the likelihood of lithium plating in areas not coated with LPM. For example, copper (Cu) has low lithium affinity, but its lithium affinity increases when it is converted into copper oxide (CuxOy). We found that this effect could be maximized by applying a minimal amount of LPM coating—sufficient to ensure performance—while compensating for the lithium affinity of uncoated areas. As a result, we were able to minimize the reduction in electrical conductivity, an essential performance property of the current collector.

Devoted to Anodeless Battery Research Built on Extensive Experience in Materials and Solid-State Batteries

Jeong-pil Lee has been engaged in solid-state battery research at LG Energy Solution since 2016. Drawing on his understanding and accumulated experience with various materials, he conducted intensive research for six months and subsequently filed a patent application for anodeless battery technology in October 2021.

Q. Which of your experiences were useful during your research on anodeless batteries?

My broad interests and diverse research experience have been invaluable in working with new technologies. I mainly conducted research on materials rather than on batteries themselves. So when I first began studying batteries, I approached them by focusing on the material reactions and properties rather than on their structure. While battery specialists tend to focus on the structure of the cell itself, materials specialists concentrate more on material properties. Through collaboration and exchanging opinions with others, I learned to view problems from multiple perspectives, which allowed me to establish entirely new directions and challenges in my research.

When I first joined LG Energy Solution, I worked on the Cell Development Team, where I learned to consider not only materials but also the overall cell structure and design. Later, I began solid-state battery research from its early stages and gained experience with a wide range of solid electrolytes and related technologies. I believe that this extensive experience—encompassing materials, cell structure, and design—has become a strong foundation for my research on anodeless battery technology.

Q. How did LG Energy Solution support you in developing anodeless technology?

I did not initially have solid-state batteries in mind when I began researching anodeless battery technology. However, as the experiments progressed, I discovered that the technology had the potential to be applied to various types of batteries. Through continuous research, I achieved meaningful results showing that it works particularly well with solid-state battery structures, an area that later began attracting significant attention.

Behind this achievement was LG Energy Solution’s strong encouragement for patent applications. The company has a well-established system that promotes securing intellectual property, even when the outcomes are uncertain. I believe one of LG Energy Solution’s strengths lies in its ability to enhance future technological competitiveness by turning accumulated experience and know-how into intellectual property, while also placing value on immediately marketable technologies. Personally, I decided to file a patent because I recognized that the anodeless battery technology had significant meaning, and I plan to continue filing patents as I advance my research.

What Is LG Energy Solution’s Vision for the Future with Anodeless and Solid-State Batteries?

LG Energy Solution is opening a new horizon with the combination of solid-state and anodeless battery technologies. The company continues its journey to make anodeless batteries a reality.

Q. What Is the roadmap for anodeless battery development?

LG Energy Solution’s anodeless battery follows the same development roadmap as its solid-state battery technology. The company plans to commercialize anodeless battery technology in the second half of 2029. Researchers at the Future Technology Center, together with related developments, are working in close collaboration to achieve this goal.

Q. Is there anything else you would like to add?

LG Energy Solution is dedicated to creating the highest level of customer value. Guided by this philosophy, the company anticipates future customer needs and develops products that meet those expectations.

Customers want batteries that deliver outstanding performance over a long period. Anodeless batteries are expected to meet these needs by offering higher energy density than conventional ones. In particular, when combined with solid-state batteries, they will provide safer and higher-performing energy solutions. I envision a future where anodeless technology emerges as a core driver of customer value.

Developing a single next-generation battery requires enormous effort. There are numerous challenges to address—from battery design and conceptualization to securing the technologies needed for implementation and ensuring commercial viability. I will remain committed to securing breakthrough technologies that enable a quantum leap, working in collaboration with many teams, including the Future Technology Center.

We covered the development of anodeless batteries by Jeong-pil Lee of the Future Technology Center. His story revealed that his research was grounded in extensive experience with solid-state batteries and informed by diverse perspectives. These efforts have helped pave the way for combining solid-state and anodeless technologies, further expanding the possibilities of next-generation batteries. Please continue to follow LG Energy Solution’s journey as it strengthens its technological competitiveness and leads the advancement of next-generation energy solutions.

- Slot-Die Coating: A technique in which slurry, an intermediate material, passes through a slot die, a coater head that serves as a mold, to form a coating with uniform patterns and thickness ↩︎

- Comma Coating: A technique in which slurry or liquid solution is applied uniformly onto the current collector, with coating thickness controlled by adjusting the gap between the comma die and the collector ↩︎

- Gravure Coating: A technique in which a rotating roll is immersed in the coating liquid, transferring the liquid onto its surface, which is then applied to the current collector ↩︎