Major cities around the world today face a range of complex challenges—from housing and environmental to traffic. One of the primary causes of these urban problems is the concentration of populations in large metropolitan areas. In particular, the increasing population density has made it difficult to systematically manage the soaring demand for transportation on already limited urban infrastructure, leading to severe traffic congestion and environmental concerns.

A promising solution to these urban traffic problems is Urban Air Mobility (UAM). Seen as a paradigm-shifting form of future mobility, UAM is gaining attention for its potential to reshape urban transportation. And at the heart of UAM’s performance lies one critical component: the battery. In this article, we’ll explore what UAM is and examine the battery technologies researched for UAM applications.

What Is Urban Air Mobility (UAM)?

Urban Air Mobility (UAM) refers to a transportation system that utilizes the airspace approximately 300 to 600 meters above urban areas. UAM encompasses not only simple air transportation but also the development of aircraft, infrastructure building, operational platforms, transportation services, and maintenance, covering the entire ecosystem of air mobility.

Traditional aviation mobility is characterized by long-distance, high-speed transportation methods. However, the need to disperse the enormous travel demand generated within and between cities has emerged, leading to increased interest in UAM as a new transportation solution to play such a role. As a next-generation mode of transportation, UAM is expected to alleviate urban traffic congestion and facilitate the rapid movement of people and goods.

eVTOL: An Eco-Friendly and Efficient Mode of Flight

Aircraft used in UAM include flying cars, PAVs (Personal Air Vehicles), and eVTOLs (electric Vertical Take-Off and Landing aircraft).

Flying cars, capable of traveling both on roads and through the air, were among the earliest UAM aircraft concepts. However, their internal combustion engines posed challenges such as pollution, noise, and the need for runways—making them less suitable for efficient intra-city travel.

PAVs have emerged to overcome these limitations. Combining the strengths of drones and aircraft, PAVs run on battery-powered electric motors, making them environmentally friendly and low-noise in operation. Their ability to take off and land vertically further minimizes spatial constraints. Depending on takeoff and landing methods, PAVs are categorized into STOL (Short Take-Off and Landing) and VTOL (Vertical Take-Off and Landing), with VTOLs requiring no runway.

Today, UAM aircraft are evolving further into eVTOLs, which is the primary focus of research. eVTOLs are electric-powered aircraft capable of vertical take-off and landing without the need for runways. Recently, research has also been conducted on establishing a UAM ecosystem that enables eVTOLs to take off and land safely at vertiports1 located throughout urban areas. Additionally, because eVTOLs operate on electric power, they produce no carbon emissions and offer various advantages such as low noise, autonomous flight, and unmanned operation.

Essential Battery Features for UAM: Endurance in Extreme Conditions

UAM is transforming into an aircraft platform well-suited for real-world urban environments, with a particular focus on the research and development of eVTOL. The key to the performance of these eVTOLs lies precisely in their batteries.

The batteries used in eVTOLs require much more sophisticated performance than those used in standard electric vehicles. This is because they must accommodate the unique operational environment of flying aircraft. eVTOLs need to adapt to variables such as altitude changes, temperature fluctuations, and continuous operation, all while maintaining stable performance even under extreme conditions.

Therefore, batteries installed in eVTOLs must meet conditions such as lightweight design, high output, and high energy density. Since the aircraft’s weight directly impacts fuel efficiency and flight duration, the battery needs to be as lightweight as possible. At the same time, high power output and high energy density are essential to enable vertical takeoff and landing, as well as long-distance flights. In other words, eVTOL batteries must balance reduced weight with sufficient capacity to ensure optimal performance.

Thermal stability and safety are also critically important. The battery must operate reliably even under conditions of continuous altitude changes and rapid external temperature fluctuations. To achieve this, more advanced Battery Management Systems (BMS) are required. These systems go beyond simply providing high performance and high output; they need to monitor the battery’s condition in real-time during flight and maintain optimal performance consistently.

What are the Promising Next-generation Batteries Suitable for UAM?

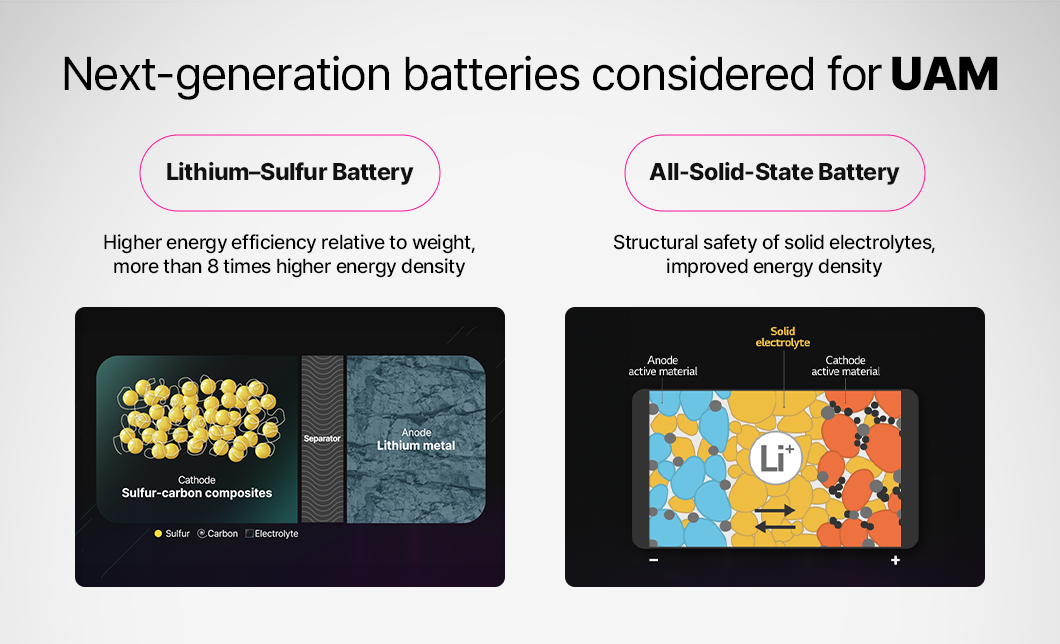

For UAM batteries that meet the requirements of lightweight design, high performance, and safety across various flight environments, lithium-sulfur batteries and solid-state batteries are considered among the top candidates.

Lithium-sulfur batteries use a sulfur-carbon composite for the cathode and lithium metal for the anode. Compared to conventional lithium-ion batteries, they offer significantly higher energy density at a much lighter weight. Sulfur has a theoretical capacity of 1,675 mAh/g, and lithium offers 3,500 mAh/g—both more than eight times the performance of typical NCM cathodes (200 mAh/g) and graphite anodes (350 mAh/g). This makes lithium-sulfur batteries exceptionally efficient in terms of energy per unit weight, meeting both the lightweight and high-performance needs of eVTOLs.

Another promising next-generation technology is the solid-state battery, which replaces liquid electrolytes with solid electrolytes. This eliminates risks of leakage and explosion, and allows safe operation even under external impact or high temperatures, ensuring safety in various environments like urban airspaces. Moreover, by removing the separator and using solid electrolytes, solid-state batteries can achieve higher energy density by allowing for more active material to be packed in. As a result, solid-state batteries are gaining attention as suitable next-generation batteries for eVTOL applications.

LG Energy Solution Leads Battery Innovation to Open the Skies

LG Energy Solution recognized the potential of UAM as a future mode of transportation early on and has proactively committed to developing the battery technologies needed to support it. The company has been conducting ongoing research into next-generation batteries optimized for UAM aircraft through its Future Technology Center established in 2023.

This has led to significant breakthroughs in various next-generation battery technologies. In particular, in the field of lithium-sulfur batteries, LG Energy Solution has addressed critical technical challenges hindering commercialization through joint research with KAIST. LG Energy Solution enhanced stability by reducing electrolyte usage by over 60%, and introduced fluorinated ether solvent technologies to suppress electrode corrosion, significantly improving the stability of lithium-metal anodes. At the same time, the company resolved issues related to electrolyte decomposition.

As a result, they have achieved significant breakthroughs in various next-generation batteries. In particular, through joint research with KAIST in the lithium-sulfur battery field, they have addressed critical technical challenges hindering commercialization. They reduced electrolyte usage by over 60%, enhancing stability, and introduced fluorinated ether solvent technologies to suppress electrode corrosion and electrolyte decomposition, significantly improving lithium metal anode stability. Simultaneously, they resolved issues related to electrolyte decomposition.

LG Energy Solution is applying its core battery technologies not only to UAM batteries but also to a wide range of product portfolios. Their solutions are also used in marine vessels and humanoid robots, as well as other fields that also demand high power, lightweight design, and high safety. With its advanced technology and strong patent portfolio, the company plans to expand its capabilities into various new applications.

UAM is more than just flying cars—it represents a new sustainable transportation infrastructure for the future. And the key enabler of UAM commercialization is advanced battery technology.

LG Energy Solution is accelerating the commercialization of UAM by developing next-generation batteries, aiming to make sky mobility a routine part of daily life. It is committed to further advancing battery technology to open the skies.

- Vertiport: A terminal designed for vertical take-off and landing aircraft that enables takeoff, landing, charging, maintenance, and passenger boarding. It is a core component of the UAM infrastructure. ↩︎