Lithium prices are skyrocketing according to recent news related to EV batteries. Why is lithium, among the cathode materials for EV batteries, receiving special attention? Today, we will explore the types and differences of lithium!

Q. Why is lithium important for rechargeable batteries?

Lithium is a critical ingredient for rechargeable batteries. There are four components that make up a battery: cathode, anode, electrolyte, and separator. Out of them, lithium is a key cathode material that determines the capacity and voltage of a battery.

When mixed with precursors like nickel, cobalt, and manganese, lithium compounds produce the finished cathode material. However, since lithium is hard to utilize in its pure form, it is used after processing into a compound.

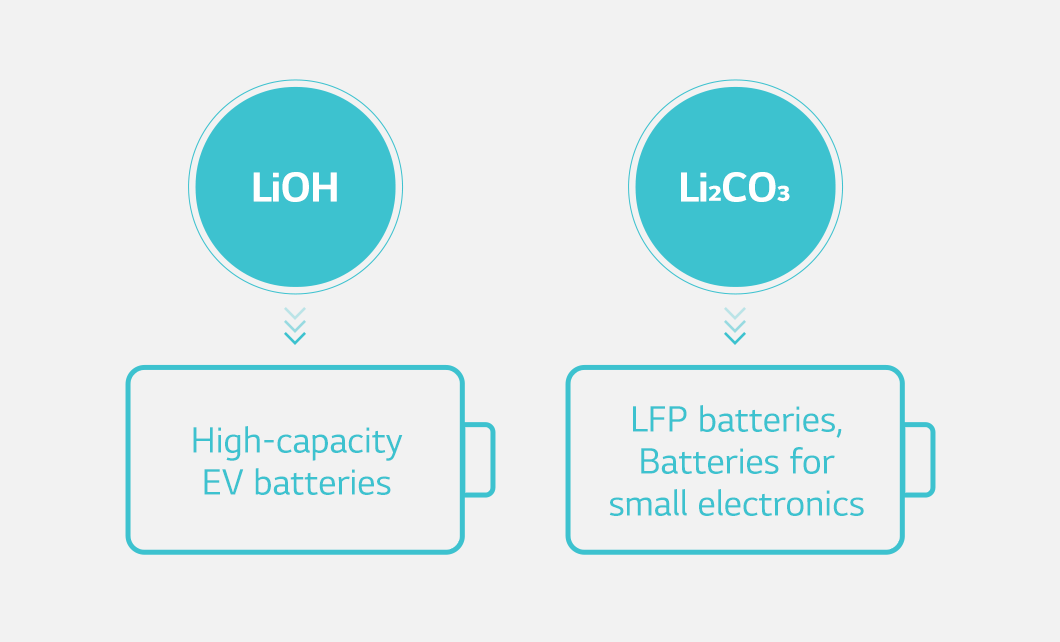

The types of lithium compounds used in battery manufacturing include “lithium hydroxide (LiOH)” and “lithium carbonate (Li₂CO₃)”.

Q. What is the difference between lithium hydroxide (LiOH) and lithium carbonate (Li₂CO₃)?

Lithium hydroxide is mainly used for EV batteries that feature high density and high capacity. This is because lithium hydroxide is easily synthesized with nickel that increases the battery’s energy density when formulating cathode materials. Thus, secondary batteries made using lithium hydroxide are generally classified as nickel-bonded *ternary cathode batteries such as NCM and NCA. Demand for lithium hydroxide is rising further as high nickel batteries that have a nickel content of more than 60% command attention.

Lithium carbonate is mainly used to make *LFP batteries for small EVs with iron phosphate in the cathode, as well as batteries for home electronics and IT devices that demand relatively low energy density.

(*Ternary cathode battery: A battery with three metal elements of lithium cobalt oxide (LCO), nickel, and another in its cathode)

*Learn more about ternary cathode battery

(*LFP battery: A battery with a cathode consisting of LFPO, a combination where iron phosphate replaces cobalt of lithium cobalt oxide (LCO))

*Learn more about LFP battery

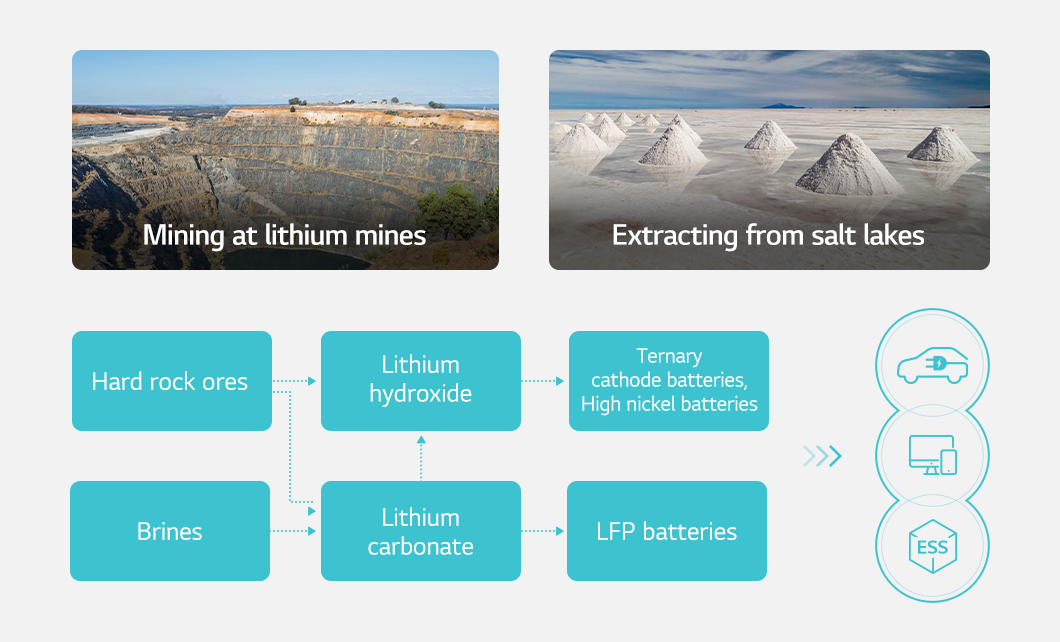

Q. How are lithium hydroxide and lithium carbonate made?

Commercial lithium can be obtained by either mining at lithium mines or extracting from *salt lakes. Once pure lithium is obtained, it goes through the process of converting into compounds for appropriate usage. Mined lithium can be turned into lithium hydroxide or lithium carbonate through further processing like heating and filtration. Also, lithium acquired from salt lakes can be transformed into lithium carbonate by evaporating the salt water, and then into lithium hydroxide by processing or converting the lithium carbonate.

*Salt lake: A lake that has a high concentration of salts.

Q. Why is it important to secure lithium?

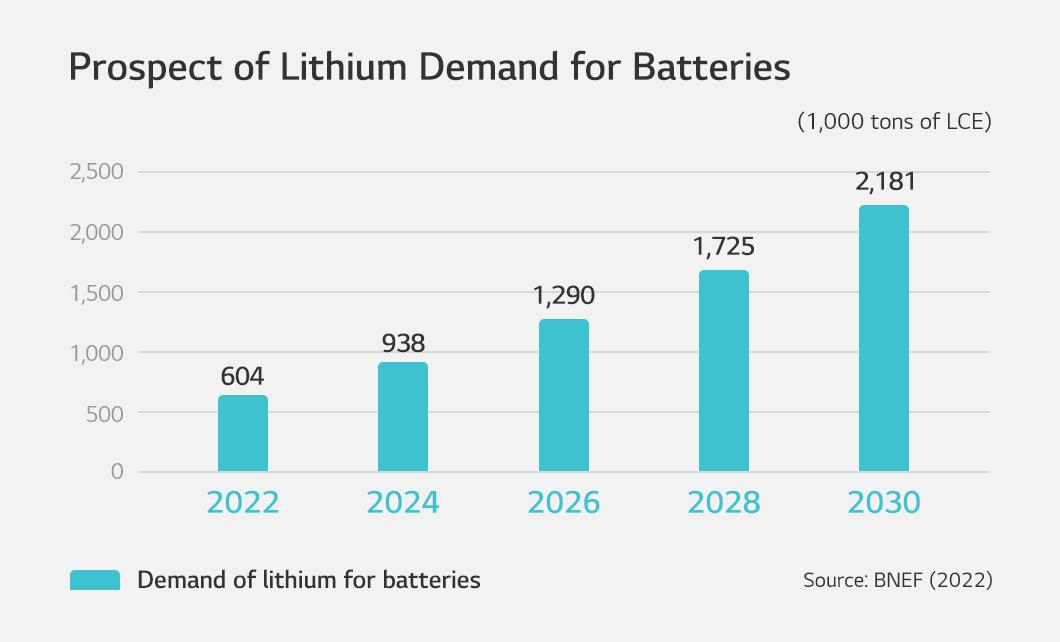

In the era of EVs, lithium is in high demand worldwide. Lithium is expected to be used as a core material not only in the currently popular lithium-ion batteries but also in next-generation batteries such as all-solid-state batteries and lithium-sulfur batteries, and the demand for lithium is expected to continue growing.

According to the United States Geological Survey (USGS)’s 2021 report, global lithium reserves were 89 million tons. Major lithium producers include Australia, Chile, China, Argentina, and Brazil, with Latin American countries holding 60% of the total lithium reserves. Since lithium mining and processing into lithium compounds is a lengthy process, it is challenging to respond to demand immediately.

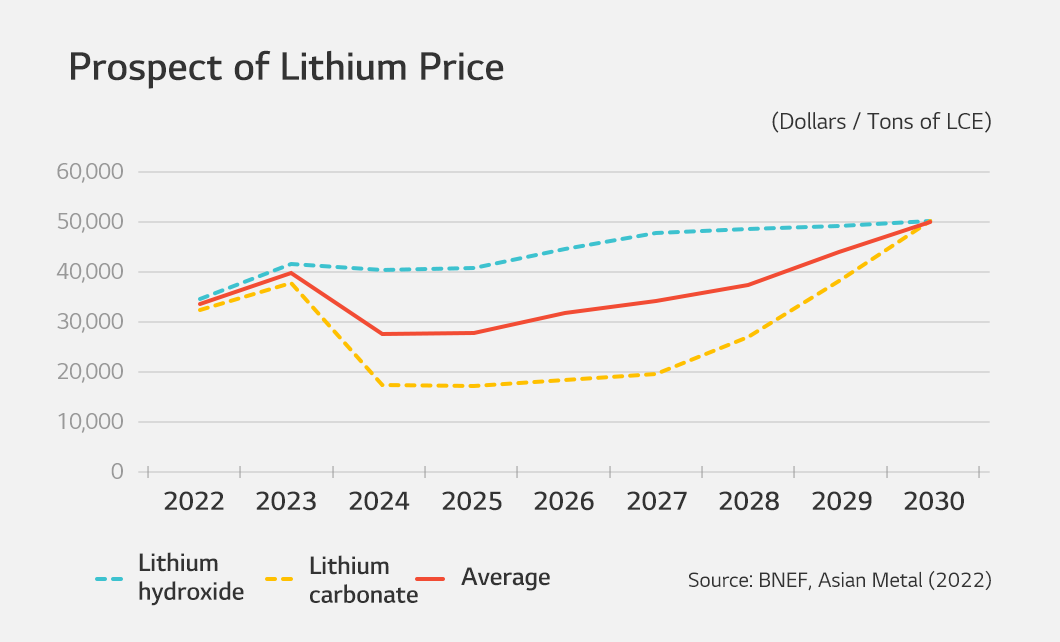

Lithium accounts for 60-70% of cathode material costs, and cathode materials account for 52% of battery costs. Since the cost increase of lithium leads to the price increase of EVs as well as batteries, it is crucial to secure lithium in advance.

Q. What is LG Energy Solution doing to secure lithium?

LG Energy Solution is diversifying its supply chain for lithium carbonate and lithium hydroxide to respond to the current trends in the global raw material market. Recently, LG Energy Solution signed a long-term supply contract for lithium carbonate with Compass Minerals and will be supplied 40% of the annual lithium carbonate produced by the American company for six years following 2025. In addition, LG Energy Solution signed a supply agreement for lithium hydroxide with Vulcan Energy of Germany and will be supplied 45,000 tons of lithium hydroxide for five years from 2025.

The supply contracts are even more meaningful as both Compass Minerals and Vulcan Energy produce lithium in an eco-friendly way. Such achievements will help LG Energy Solution strengthen its ESG competitiveness for carbon neutrality.