In the assembly process of pouch-type batteries, once a cell stack is formed using the Lamination & Stacking method, the process moves on to the pack process. What steps does a pouch-type battery go through? Let’s find out!

Relatively Simple Assembly Process

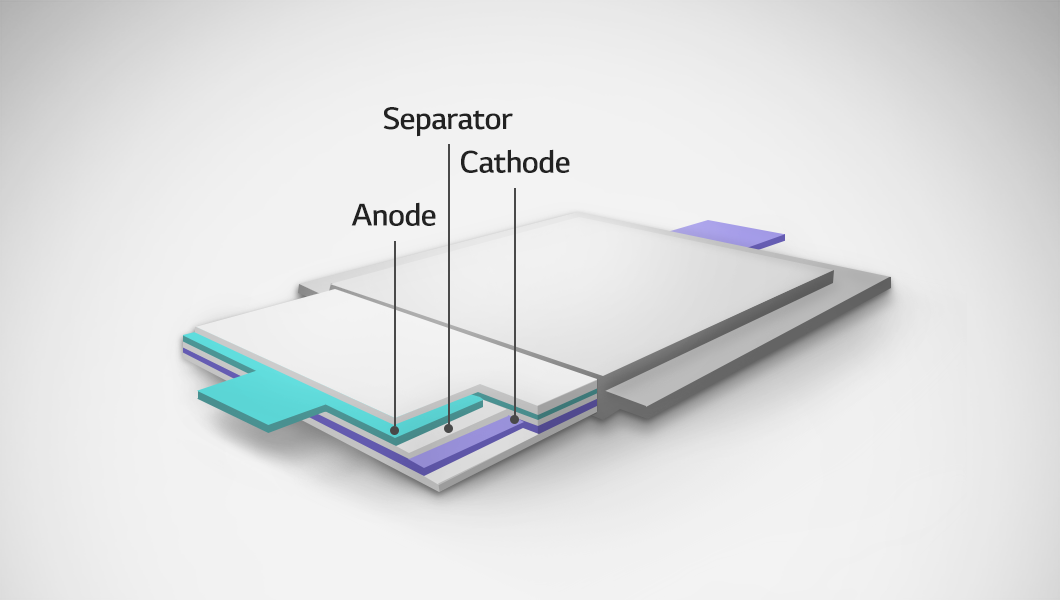

To make a pouch-type battery, we need a pouch case and battery ingredients consisting of the cathode, anode, separator, and electrolyte. Unlike cylindrical batteries, pouch-type batteries are simple to assemble because they do not need cans and parts.

Manufacturing a Pouch Case and Assembling a Cell Stack

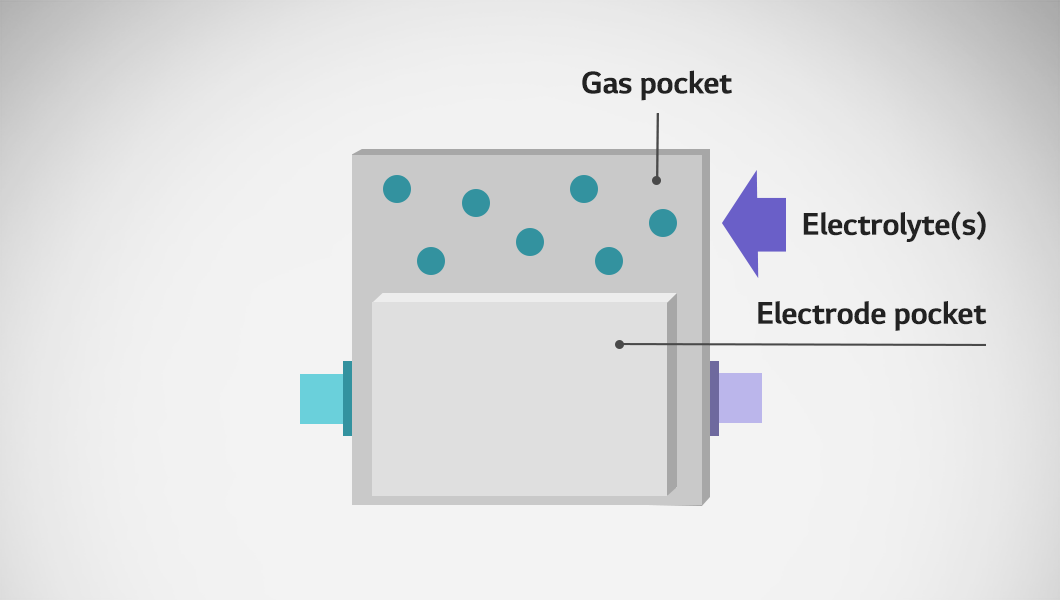

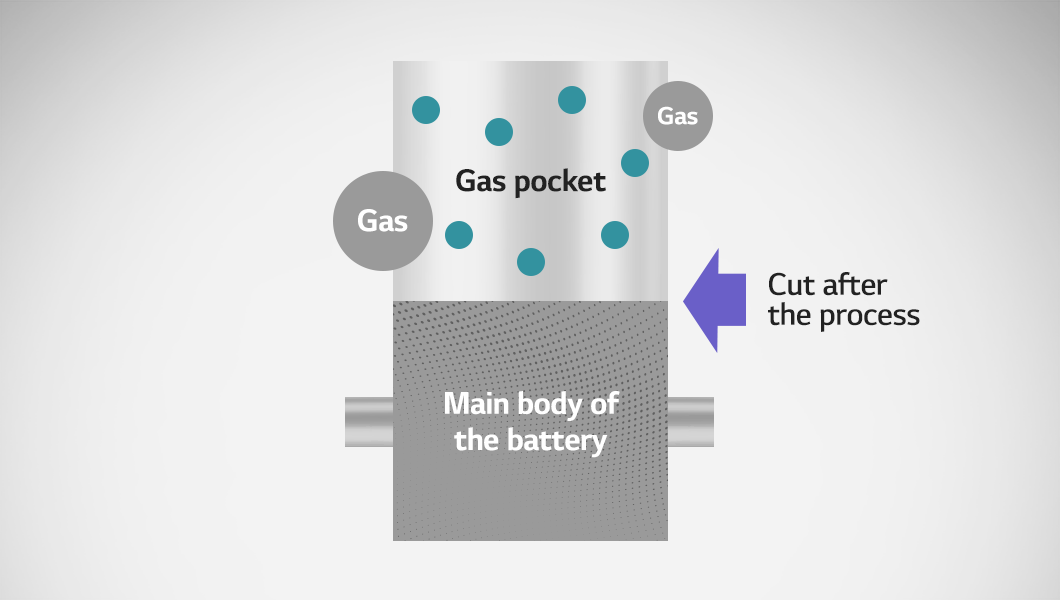

A cell stack produced through the lamination & stacking is first welded with leads. Then, the pouch film is compressed to form the pouch case. Through this process, electrode pockets, which hold the battery materials, and gas pockets, which store gas and allow for electrolyte injection, are created. Next, the lead-welded cell stack is inserted into the pouch pocket and assembled. Then, a sealing tool is used to apply heat and pressure to seal.

Electrolyte Injection

Afterward, electrolyte is injected into the electrode pockets through the gas pocket, ensuring it reaches the pores within the electrodes. Finally, the injection port is sealed using the sealing tool, completing the assembly process of the pouch-type battery.

Meanwhile, during the formation process, which takes place after assembly, unnecessary gas is generated and accumulates in the gas pocket. During the degassing process, the gas pocket is cut off to remove the unwanted gas.

We’ve explored the cell assembly of pouch-type batteries. Next, we’ll take a look at how cylindrical batteries are assembled!