The rapidly growing electric vehicle market generates a growing number of end-of-life batteries. By 2030, we will have around 90GWh of spent batteries retiring worldwide. Thanks to the challenging nature of spent battery treatment and the potential of recycling raw materials in batteries, the global end-of-life battery market would reach USD 150 billion by 2030 and USD 470 billion by 2050. This is why local governments and many companies in Korea are keenly eyeing used batteries.

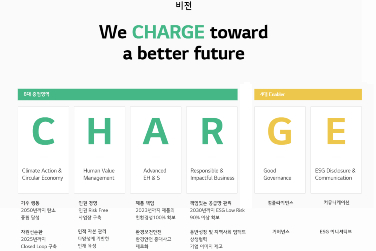

LG Energy Solution is also striving to lead by establishing a circular battery system in which end-of-life batteries become a source of new batteries.

To this end, the South Korean battery giant is adopting the system in its regional battery manufacturing plants to prevent environmental pollution and generate sustainable value. It aims to reuse and recycle end-of-life batteries by extracting raw materials. It is also working on building a cooperative model with major automakers to reliably source and recycle spent batteries.

Lithium-ion batteries retired from electric vehicles due to degradation over time can be repurposed for other applications since it retains high energy density. LG Energy Solution develops business models and application technologies utilizing retired electric vehicle batteries. One example of which is accurately predicting the battery life of used batteries. The company is also working with related parties to develop an optimal business model for end-of-life batteries.

The battery maker strives to create a virtuous cycle of recycling reused spent batteries that have reached their end of life. After disassembling, refining, and smelting, rare metals such as lithium, cobalt, and manganese would be extracted from the batteries.

China has established a resource circulation system where spent batteries or scraps generated during battery manufacturing are sold to recycling companies for rare materials extraction. The extracted materials, such as nickel and cobalt, would then be used to manufacture cathode materials. The Korean, European, and American counterparts also strengthen strategic cooperation to develop a recycling business model.

In May 2021, LG Energy Solution signed a recycling contract with Li-Cycle, the largest recycling company in North America, through Ultium Cells, a joint venture with GM in the United States. Ultium Cells will recycle various raw materials such as cobalt, nickel, lithium, graphite, copper, manganese, and aluminum extracted from end-of-life batteries and generated during the cell manufacturing process.

In June 2021, LG Energy Solution set up the Reuse Battery Project in its Ochang Plant. It is an electric vehicle charging ESS system, demonstrating the high value of reusing batteries. The system is powered by retired batteries from electric taxis with a mileage of over 100,000 km. The ESS system saves costs by charging the system at night when electricity rates are low. It charges electric vehicles during the day when the rates are high. One hour of charge with a 100kw charger gives GM’s Volt a range of 300km, demonstrating decent performance.

The move to strengthen environmental regulations towards carbon neutrality and the growing need to establish a virtuous resource system draw attention to the end-of-life electrical vehicle battery industry. Harnessing its leading technologies and continued R&D and investment, LG Energy Solution plans to respond to the evolving trend and establish a battery circulation ecosystem. The South Korean battery giant will continue to lead the battery ecosystem by enhancing resource circulation and minimizing pollution.