Did you know that many small, lightweight devices powered by batteries are all around us? From wearable devices like smartwatches to calculators, scales, and hearing aids, various applications make our lives more convenient. What enables them to operate and deliver performance is the coin cell battery installed inside each device. Let’s take a closer look at this small yet powerful battery — the coin cell.

What Is a Coin Cell?

As its name suggests, a coin cell is a flat, disc-shaped battery shaped like a coin. The diameter and thickness vary depending on the application, but most are designed to be thin and lightweight in a circular form.

A secondary coin cell is structurally identical to a typical lithium-ion battery, consisting of a cathode, anode, separator, and electrolyte. A representative coin cell measures 12 mm in diameter and 5.4 mm in thickness — about one-twentieth the volume of a cylindrical 18650 cell.

Despite its small size, it can store sufficient energy and supply power stably. It also maintains a consistent voltage and retains energy for long periods even when not in use, making it ideal for precise, compact devices.

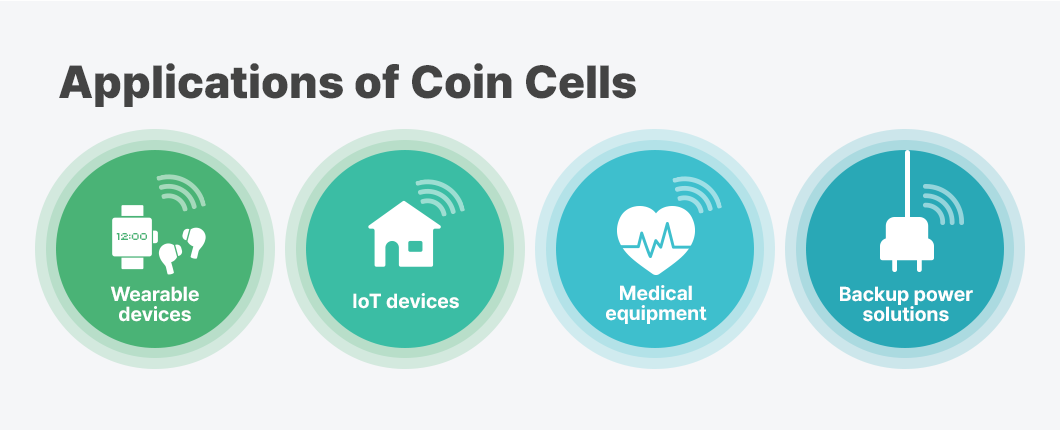

Thanks to these characteristics, coin cells are widely used in wearable devices such as smartwatches and fitness bands. They are also used in highly reliable and long-lasting medical devices like hearing aids and insulin pumps, as well as rechargeable IoT (Internet of Things) devices that require long standby times. In addition, coin cells serve as stable backup power solutions for RTC (Real-Time Clock) systems and memory backup power.

In particular, coin cells play a crucial role in battery research and development. When testing new materials or manufacturing processes, researchers produce small cells in coin-cell form to quickly verify performance.

LG Energy Solution Introduces Automated Coin Cell Production Equipment to Strengthen Research Competitiveness

LG Energy Solution not only supplies coin cells to the battery market but also actively utilizes them in next-generation battery research and development. In particular, the company has introduced automated production systems for coin cell fabrication to enhance research efficiency.

Previously, researchers manually assembled each coin cell by hand. With the introduction of automated systems, however, up to 360 units of the LIR2032 cell (20 mm in diameter, 3.2 mm in thickness) can now be produced per day. This system delivers productivity equivalent to the work of four researchers, allowing them to focus more on experiment design and material analysis rather than repetitive cell assembly.

The introduction of coin cell automation has also minimized potential human errors and variations that could arise from manual assembly. As a result, sample quality consistency has significantly improved compared to before, while evaluation precision has been maximized.

Small but mighty, coin cells are proving their importance not only in wearable devices but also in research and development processes. With initiatives such as the introduction of automated coin cell manufacturing systems, LG Energy Solution will continue to advance high-efficiency, high-precision battery research and further strengthen its competitiveness in next-generation technologies.