You may have come across the term “Mono-Cell” in the pouch-type battery cell assembly. The mono-cell is the most fundamental component in the pouch cell manufacturing process. Let’s explore what a mono-cell is in more detail in our Battery Glossary!

What Is a Mono-Cell?

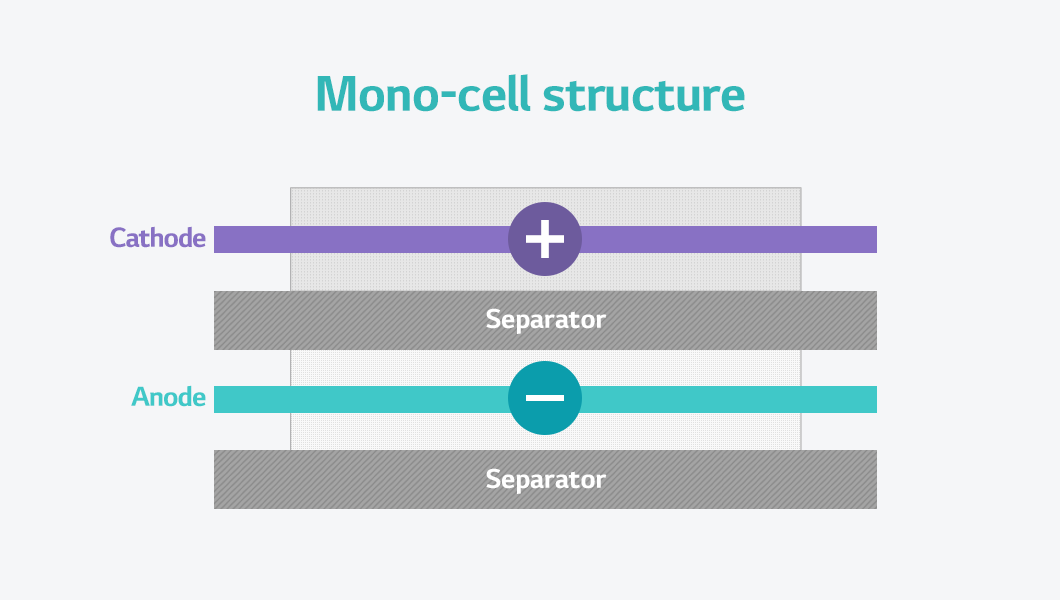

A mono-cell is the basic unit cell of a battery, consisting of electrodes such as the cathode and anode, along with two separators. Its structure is formed by stacking the layers in the order of “separator – center electrode – separator – outer electrode.” In simpler terms, separators are placed on both sides of a center electrode, and then an electrode of the opposite polarity is stacked on the outside.

In the pouch-type battery cell assembly, lead tabs are welded onto cell stacks that are produced through the lamination and stacking method. These cell stacks are then inserted into a pouch casing. Multiple mono-cells are used to create each cell stack.

Difference Between Mono-Cell and Bi-Cell

Both mono-cells and bi-cells are unit cells, representing semi-finished subunits in the cell assembly of battery manufacturing.

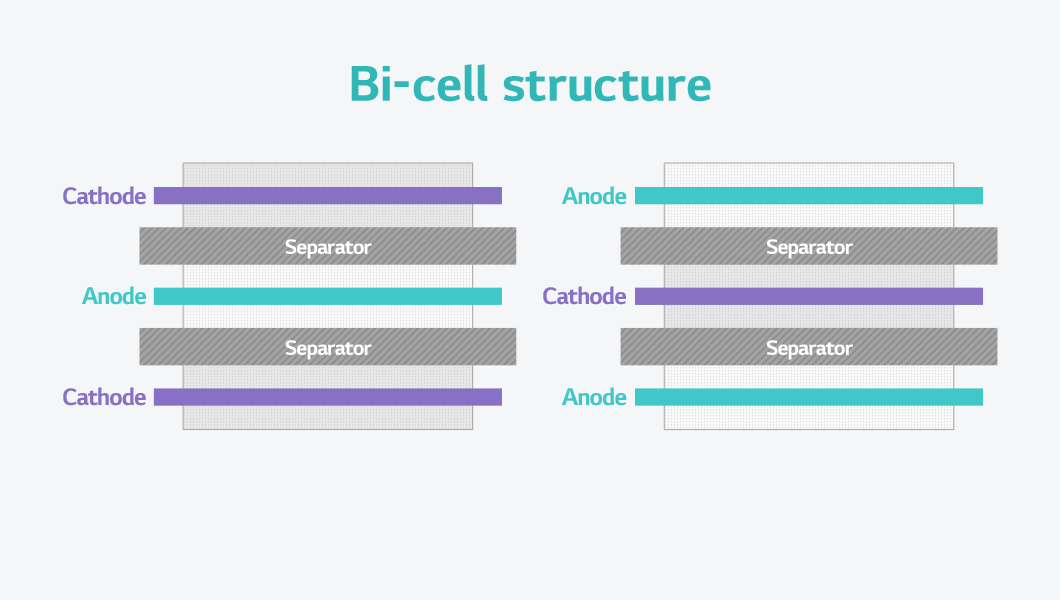

Meanwhile, mono-cells and bi-cells have different structures. The structure of a bi-cell typically is either “cathode/separator/anode/separator/cathode” or “anode/separator/cathode/separator/anode,” where the outermost electrodes are of the same polarity. While a mono-cell consists of one cathode and one anode, a bi-cell is composed of two cathodes and one anode or two anodes and one cathode. Additionally, mono-cells are typically applied in lamination and stacking methods used for making cell stacks, whereas bi-cells are mainly used in stacking and folding techniques.

Mono-Cells in the Pouch-type Battery Cell Assembly

Then, how exactly are mono-cells used in the pouch-type battery cell assembly?

First, the cathode, anode, and separators are aligned and bonded through lamination to form a mono-cell. These mono-cells are then repeatedly stacked on top of each other through the stacking process. Finally, a half-cell composed of two separators and an anode is placed on top to complete the “cell stack.”

Once the cell stack is complete, the packaging process begins. Pockets are formed by pressing pouch film, and the cell stack with welded leads is inserted into the pocket. After that, the electrolyte is injected, and the injection port is sealed using a sealing tool. This completes the pouch-type battery cell assembly.

We’ve now covered the mono-cell, the basic building block of batteries. Hopefully, you can now clearly distinguish the differences between mono-cells and bi-cells. Stay tuned for more easy explanations of complex battery terms in our Battery Glossary!