The anode material determines the charging speed and lifespan of a battery. Since the anode material directly affects battery charging and discharging performance, the battery industry is focusing on developing anode materials based on the characteristics of various materials and the latest research trends.

*View Anode Material Types (Infographic #18)

Among these, silicon anode materials are being actively researched as they can increase energy density, particularly through efforts to combine silicon with other materials. This infographic will examine silicon oxide and silicon-carbon composites one by one, among the various types of silicon anode materials.

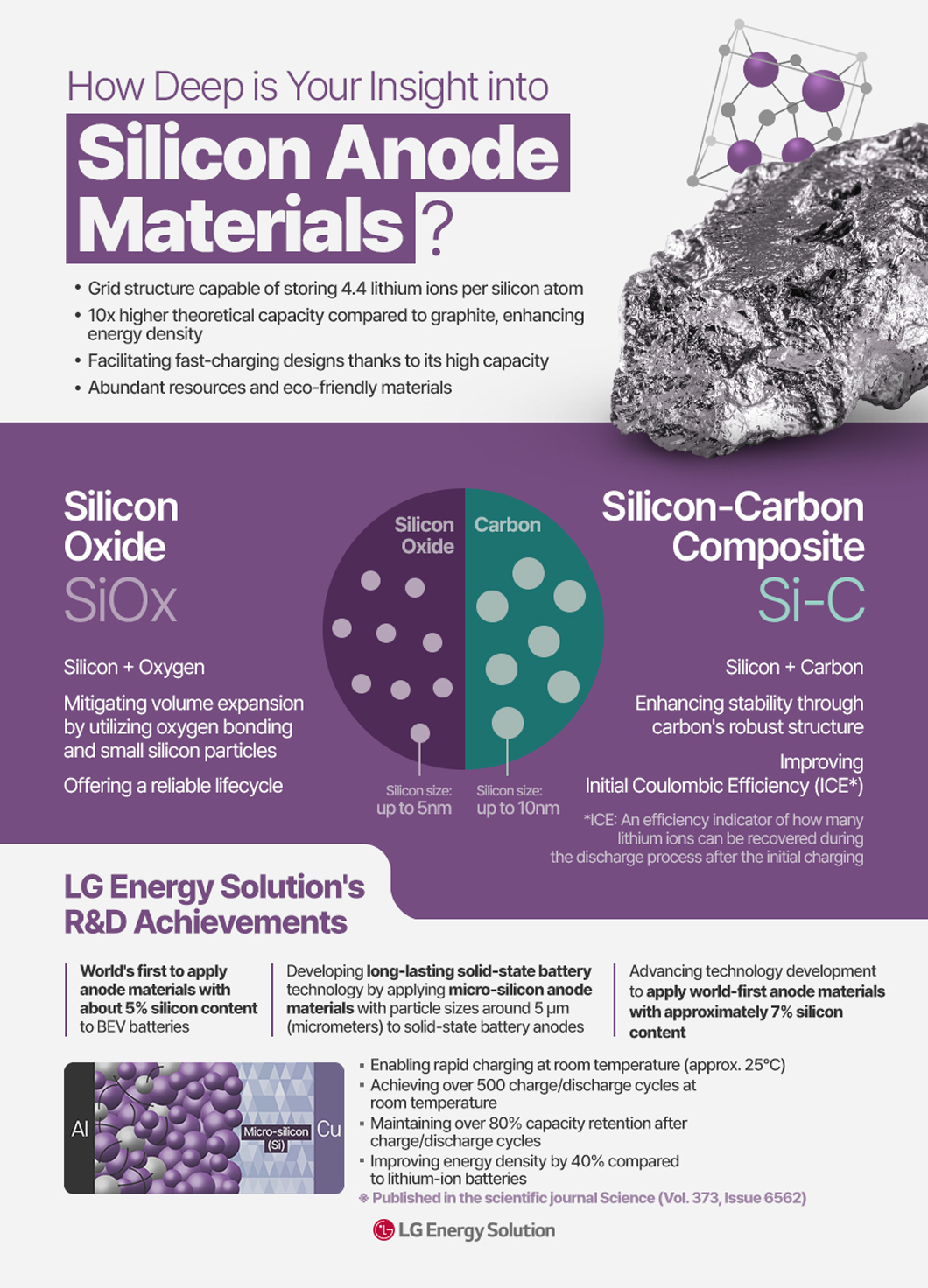

Silicon anode materials, achieving high energy density with high theoretical capacity

Silicon anode materials are gaining attention as the need for high-capacity and high-performance batteries increases. Graphite, a common anode material, can store one lithium ion per six carbon atoms, while silicon anode materials can store 4.4 lithium ions per silicon atom. In this way, silicon anode materials have a theoretical capacity approximately 4 to 10 times higher than that of graphite. This characteristic can be utilized to enhance energy density. Another advantage is that silicon is abundant, which makes it a more economical and environmentally friendly choice.

Although silicon anode materials are considered next-generation anode materials for their ability to maximize energy density, their volume can change during charging and discharging. During charging, silicon absorbs lithium ions and its volume expands, while during discharging, it releases the lithium ions and contracts. Repeated volume changes can ultimately affect battery performance.

For this reason, the battery industry is conducting diverse research to address the characteristics of silicon anode materials. One approach under development is to use different combinations of silicon materials in anodes.

Silicon oxide (SiOx), reducing volume expansion

Silicon anode materials are classified into silicon oxide (SiOx) and silicon-carbon composites (Si-C), depending on the internal materials. SiOx is a material formed by combining silicon and oxygen and is produced by synthesizing oxide-based silicon onto silicon particles.

Using SiOx helps mitigate the volume expansion. In particular, its particle size is more than 10 times smaller than that of Si-C, making it more effective at suppressing silicon volume expansion. The oxide formed during charging and discharging also acts as a buffer for volume changes, reducing stress within the electrode. Additionally, SiOx offers a higher initial capacity compared to Si-C.

However, SiOx is more difficult to process than other silicon materials, leading to higher production costs. This is because advanced techniques such as vapor deposition are required during manufacturing. Another challenge is that the oxygen can bond with lithium ions, reducing their mobility and lowering charging and discharging efficiency.

Silicon-carbon (Si-C) composites, improving charging & discharging efficiency and electrical conductivity

Along with SiOx, silicon-carbon (Si-C) composites are also gaining attention as a silicon anode material. Si–C composites are materials made by combining carbon with silicon, offering both the high capacity of silicon and the stable charging and discharging performance of carbon (graphite). Among silicon-based anode materials, Si-C composites are relatively easier to research and process, and tend to exhibit higher initial coulombic efficiency (ICE).

However, their lifespan is shorter than that of silicon oxide, requiring further research to overcome this limitation.

LG Energy Solution is leading silicon anode materials research across various fields

LG Energy Solution has made significant R&D achievements in silicon anode materials. In 2019, the company applied an anode material with 5% silicon content to a battery electric vehicle (BEV) for the first time in the world. In 2021, LG Energy Solution and the University of California, San Diego (UCSD), jointly developed long-life all-solid-state battery by applying micro-silicon anode with particle sizes of around 5 μm (micrometers).

*Curious about the all-solid-state battery? View [Battery Pioneer] All-Solid-State Battery here.

Recently, LG Energy Solution has also succeeded in developing technology to improve the performance of silicon anode materials. In December 2024, LG Energy Solution and Yonsei University jointly addressed the issue of volume expansion in silicon anode materials during charging and discharging by designing high-strength separators based on inorganic materials. As a result, batteries that applied this technology showed an excellent capacity retention rate of over 88% even after undergoing 400 cycles of fast charging and discharging.

Charging speed and safety are emerging as key factors in battery performance. LG Energy Solution is leading innovation by developing various technologies and discovering new materials. Stay tuned as LG Energy Solution continues to take on new challenges!