LG held the LG Tech Conference on March 16 at the LG Science Park in Magok, Gangseo-gu, Seoul, aimed at 350 R&D talents in science and engineering master’s and doctoral programs in Korea. Tech sessions covering 26 fields, including AI, big data, the metaverse, blockchain, and the smart factory, were planned to share the status of LG’s technological innovation and vision. As the recent rise in interest in electric cars and battery performance shows, a session got the attention of some of the talents in materials development.

Let’s take a look at Byeong-cheon Park of Cathode Material Team 1’s presentation, which covered the trends and future of battery material development during a specialized session.

Lithium-Ion Batteries and Four Key Materials

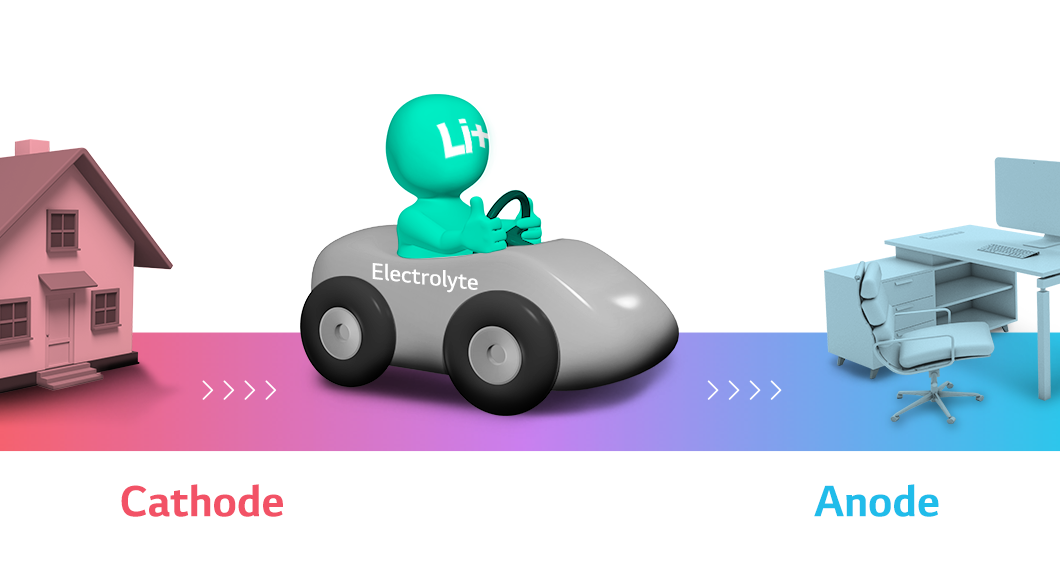

Cathode materials, anode materials, electrolytes, and separators are the four most essential materials required to manufacture a lithium-ion battery. These four materials account for nearly 90% of the total material cost. We can determine the value of the battery by conducting a direct study of them.

First, the cathode material functions as a home for lithium ions. It is made up of inorganic oxide and a transition metal. The lithium in this material determines the two most important battery characteristics: capacity and voltage. Given that it contains lithium from the start, the cathode material accounts for most of a battery’s cost. In terms of material design, it is crucial because it will impact performance relationships.

The anode material stores lithium delivered by the cathode. An electron exchange reaction occurs when lithium ions are stored and electricity is generated along the wire. The amount and speed of movement of these electrons determine charging speed. Several studies are being conducted to improve the cathode material’s functions.

A cathode material is like a building that houses lithium, whereas an anode material is like a workplace that receives lithium and uses it to make the battery work. The electrolyte serves as a medium for transporting lithium ions from the cathode to the anode. A person’s quality of life can change depending on their mode of transportation and commute time. In the same way, no matter how well the cathode and anode materials perform, if the medium connecting the two does not function properly, achieving the desired battery performance is challenging.

Finally, the separator keeps the cathode and anode materials from coming into direct contact. Electrons need to move along a wire in order to create electrical energy. Consequently, functional polymer materials that can selectively move ions are used. On top of letting lithium pass through selectively, this polymer material needs to be strong and heat-resistant to prevent the anode and cathode from contacting each other.

The Battery Development Path of LG Energy Solution

LG Energy Solution strives to develop batteries that meet energy, charging speed, cost, and safety requirements. The first is energy. When an electric vehicle is fully charged, it must be able to travel a reasonable distance. It should be less sensitive to temperature and capable of traveling a reasonable distance regardless of how cold it is. Electric vehicles on the market today have largely caught up to conventional internal combustion engine vehicles, but improvements are still needed.

The second consideration is the price. Prices can fluctuate due to a variety of factors, such as government policies, raw material fluctuations, and technological advances. We must continue to develop batteries that can mitigate the effects of these factors. Pricing is also linked to the customer experience. Customers are bound to be dissatisfied if the price difference between the person who bought it a year ago and the person who bought it now is significant or if the price suddenly drops after purchasing a new car. It will take more time to reach a price comparable to an internal combustion engine. Still, we hope to provide value beyond that of an internal combustion engine by securing a stable and competitive price.

Then there’s fast charging and safety. The most recent electric vehicle market trends are quick charging and safety. If charging takes a long time, an electric vehicle’s operation is severely hampered. It is necessary to expand the charging infrastructure, but charging times must also be reduced. There are numerous concerns, particularly about electric vehicle fires, and we intend to keep working and researching until we find a way to prevent various battery-related accidents from occurring in the first place.

Development History and Major Material Development Trends

LG Energy Solution began research and development in 1996. It has been steadily developing and applying the four major materials and has continued to take on various challenges, such as lithium polymer batteries for camcorders, cylindrical batteries, and electric vehicle batteries. As a result, it was able to claim the title of the world’s first material application in a variety of areas. This effort acted as a catalyst for collaboration and business expansion with world-class brands. LG Energy Solution is exploring how to optimize the battery development directions, balancing energy and safety, as well as rapid charging and price. We will briefly discuss the top three trends in material development.

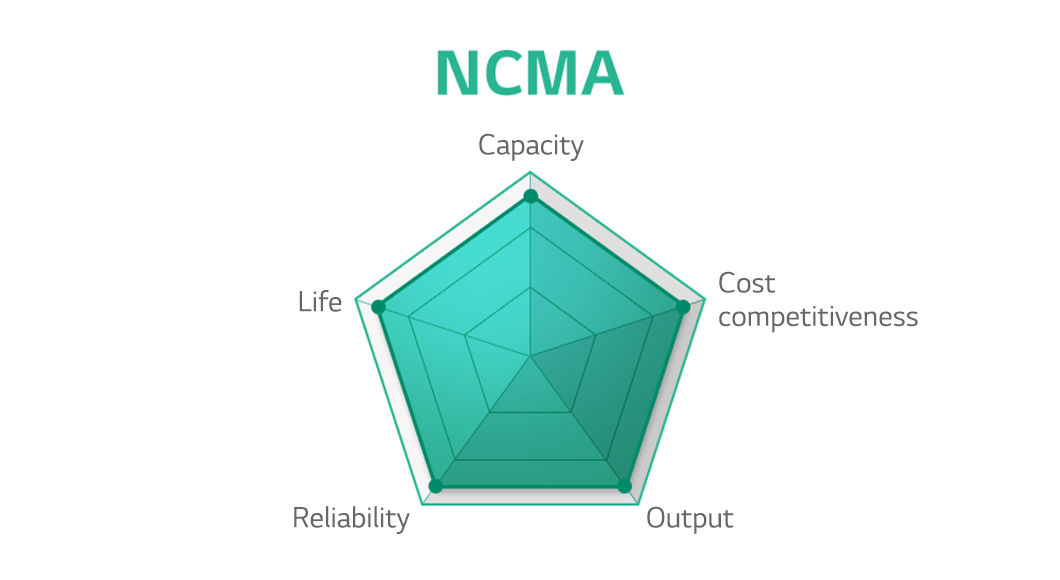

The first is single-crystal NCMA cathode material containing nickel, cobalt, manganese, and aluminum. Manganese is vital for enhancing battery safety, while nickel is essential for enhancing battery capacity. Furthermore, aluminum can improve battery safety while also lowering battery costs by reducing the expensive cobalt content.

Next are Mn-rich cathode materials and Si-based cathode materials. Mn-rich cathode materials have a slightly different structure than existing cathode materials. Also, since they can use more than 60% manganese, which is the cheapest, Mn-rich cathode materials can provide customers with batteries at a lower cost. Furthermore, due to its high stability and excellent performance, we plan to use it as a next-generation cathode material by improving cathode powder properties and developing electrolytes.

Si-based anode materials can enhance energy density because they have more than four times the capacity of graphite-based ones. However, silicon, the main raw material, is challenging to handle and can cause safety issues due to its expansion. We are looking into how to use nanotechnology to solve these problems and make it possible to store lithium quickly, which can improve the speed of charging.

We are also working on finding better performance and optimal balance for existing batteries. We expect to develop batteries that incorporate these technologies in 2 to 3 years.