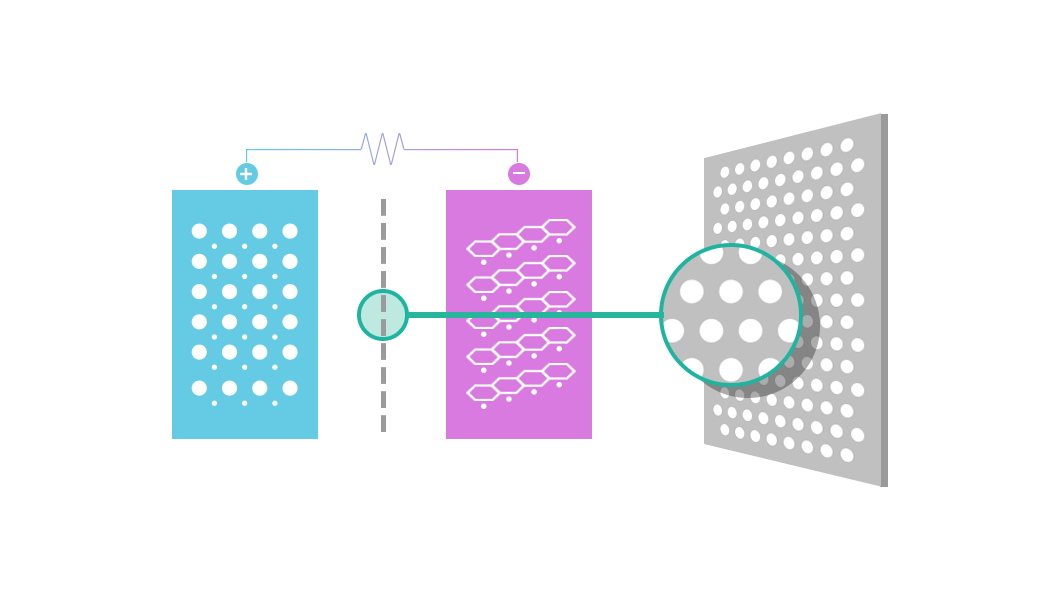

One of the major four components of lithium-ion batteries, the separator is considered an essential factor to ensure battery safety. LG Energy Solution invented separators equipped with special functions to manufacture safer batteries. Today, we’ll learn about SRS® introduced by LG Energy Solution to enhance battery safety.

Core of Separator Manufacturing

While the cathode and anode are related to battery performance, the separator has a lot to do with safety. The key in producing a separator is to prevent an internal short circuit by keeping the cathode and anode apart and to allow smooth movement of lithium ions through micropores in it.

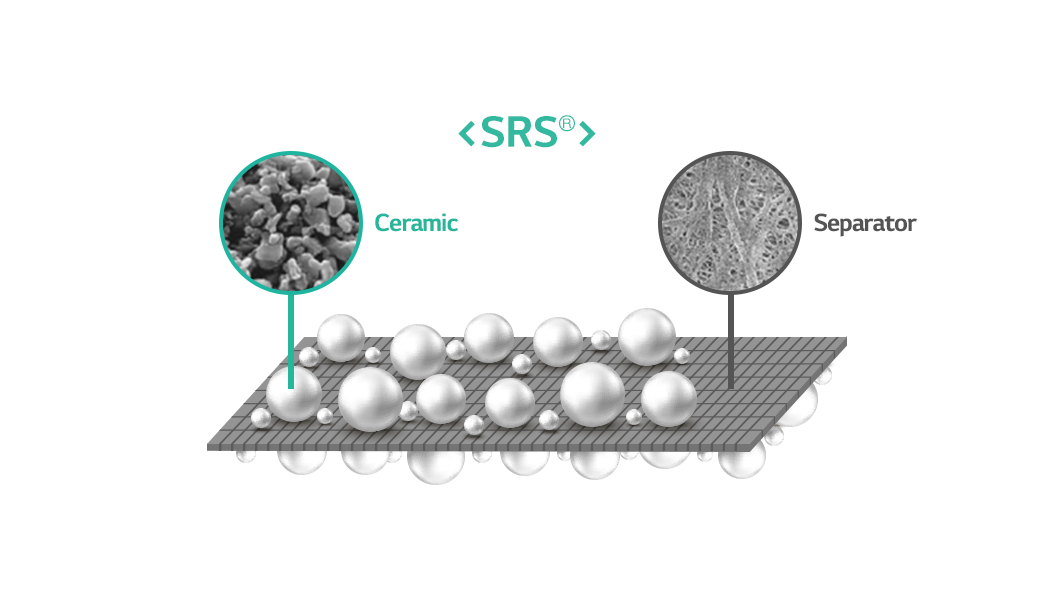

SRS®, a Separator with Enhanced Safety

In order to let a separator keep the cathode and anode apart well, it needs to be highly durable and heat resistant. So, LG Chemical that wanted to raise the safety of separators developed Safety-reinforced separator in 2004. It is a technology of applying a ceramic coating and polymer binder onto the surface of the separator.

Normally, the durability of separator decreases at a high temperature of above 100 °C. But SRS can withstand even above 200 °C. It can help energy-dense and high-output high-nickel batteries maintain high performance safely.

Enhancing output and capacity is important, but battery safety is even more crucial to support them. We could see how battery experts are striving to improve battery safety through SRS®.