How can we increase the capacity of battery packs? We can either increase the capacity of individual battery cells or increase the number of cells or modules that make up a battery pack to store more energy. Accordingly, the battery industry is developing various technologies to house more cells while also enhancing battery performance. Among them is one that removes the modularization step to add more battery cells: Cell-to-Pack (CTP).

What is Cell-to-Pack (CTP)?

Conventional battery packs are assembled in the order of cell–module–pack. In contrast, CTP eliminates the modularization step and mounts individual battery cells directly into the pack. This allows more efficient use of space, as the cells replace the module cases. In other words, it reduces unused space within the pack and improves space efficiency, thereby increasing energy density and total capacity.

By removing the module stage, CTP helps reduce raw material costs used in the process. This not only lowers costs but also shortens pack manufacturing time. In addition, CTP simplifies the internal structure of the pack, increasing design flexibility.

Difference Between Module-to-Pack and Cell-to-Pack

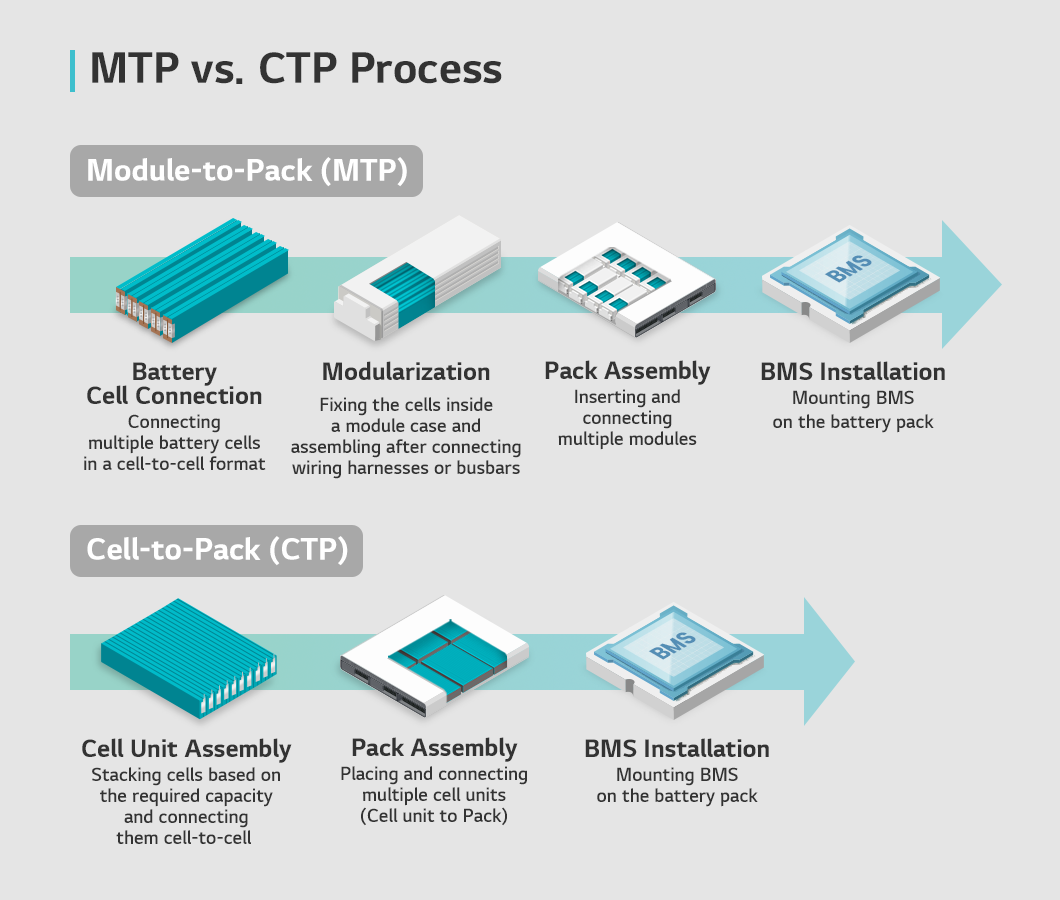

As noted, CTP is effective in enhancing energy density and production efficiency of batteries. So how does the assembly process differ from the conventional Module-to-Pack (MTP) method?

The Module-to-Pack process features a modularization step in which multiple battery cells are connected.

First, several battery cells that have undergone the formation process are connected cell-to-cell. These connected cells are then inserted into a module case that has been coated with adhesive. After the cells are secured with wiring harnesses or busbars, the upper cover of the module is placed, completing the module.

When the modules are complete, the process moves on to pack assembly and BMS installation. The modules are connected module-to-module to form a battery pack, and with the final step of installing the Battery Management System (BMS), the MTP process is completed.

*What is BMS? View Battery Glossary – BMS

Meanwhile, CTP dispenses with the modularization step.

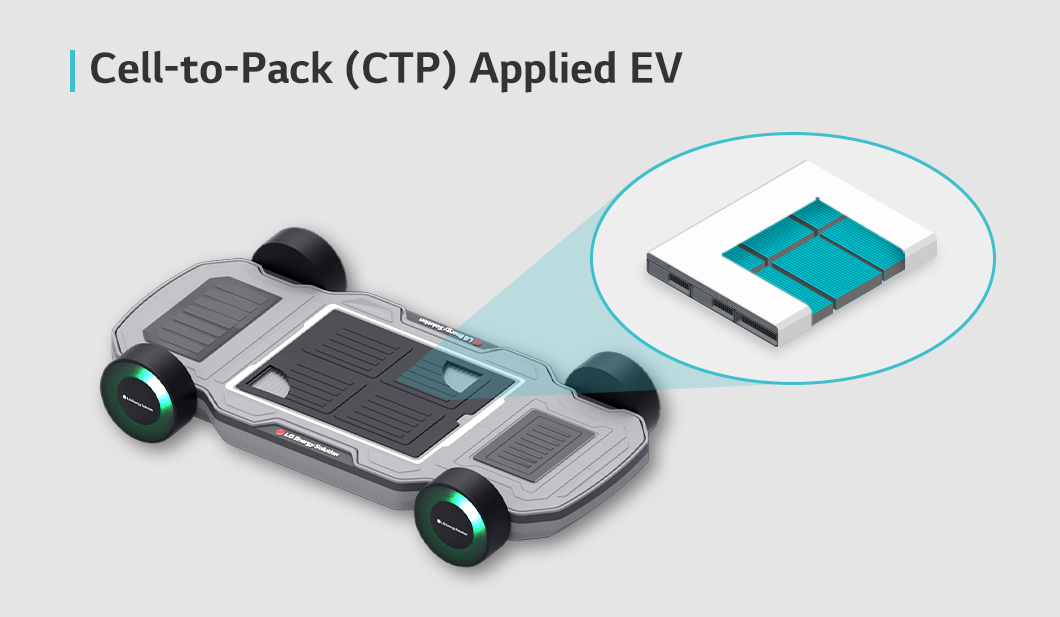

CTP begins by arranging pouch-type battery cells, either as individual cells or as stacked cell groups of two or more. Compression pads are then attached to the sides of the cells, and they are electrically connected using busbars. Next, a cell cover is placed to form a single cell unit. The unit is then positioned in the pack case, where thermal resin is applied to enhance cooling efficiency. Finally, the BMS is installed, completing the battery pack through the CTP method.

LG Energy Solution Introduces CTP for Pouch-Type Battery Assembly

CTP is emerging as a next-generation battery technology. LG Energy Solution became the first in the battery industry to apply the CTP process to pouch-type batteries. Pouch-type battery cells are lightweight and reduce dead space when multiple cells are stacked. Accordingly, when combined with CTP technology that enhances space efficiency, pouch-type batteries enable the production of battery packs that are lighter and have greater capacity.

We have explored what Cell-to-Pack technology is. If you want to dive deeper, click the article below!

*View [Battery Pioneer] Innovative Cell-to-Pack Technology that Eliminates Modules