In the previous part of our interview, we explored the key differences between BMS and BMTS by meeting with the developers behind LG Energy Solution’s BMTS, and also looked at its BMTS brand, B.around. In Part 2, we take a closer look at the efforts that went into the development of BMTS, the unique features of B.around, and the roadmap ahead.

*Click here for Part 1 of the B.around interview

The Driving Forces Behind BMTS Leadership: Relentless Drive for Technological Advancement and Massive Data Analysis

The reason LG Energy Solution was able to develop BMTS lies in the fact that every team within the BMS Development Group continuously worked to discover differentiated technologies and advance them.

According to Cheol-Taek Kim, Vice President of the Diagnostics Department, “As battery safety became increasingly important, we saw the need to enhance safety diagnostics—and our team members were completely on board with this vision. I felt immense pride watching the team members motivate themselves and devote themselves to the development of safety diagnostic technology.

LG Energy Solution has been establishing its BMTS technology through the collection and analysis of battery usage data. Of course, the process was not always smooth. This was because it required collecting and thoroughly analyzing a vast and diverse volume of data. Nevertheless, the core members of the BMTS development team overcame these challenges through close collaboration.

Vice President Cheol-Taek Kim explained, “To advance our safety diagnostic technology, we collaborated with various departments such as cell development and quality control to secure the necessary data,” and added, “We accumulated battery data in the cloud, analyzed anomalies in the data, and strengthened our technological competitiveness through that process.”

Kim added, “To enhance safety diagnostic technologies, we collaborated with teams in cell development, quality control, and other areas to secure crucial data. We stored this battery data on the cloud, analyzed anomalies, and continuously strengthened our technical edge.”

Sang-Hoon Lee, Executive Director, Service Solutions, also emphasized, “Over a period of more than three years since 2021, we have collected driving data using B-Checkup, a data acquisition device developed by LG Energy Solution, and provided a variety of customer services based on B-Lifecare, our integrated battery diagnostic service for EVs.” He added, “By continuously tuning and upgrading our algorithms based on big data, we enhanced the performance of our degradation and lifetime prediction software.”

In addition, the process of defining BMTS served as a period of deep reflection for LG Energy Solution on what true value shared with customers really means.

Dong-Geun Kwon, Team Leader of the BMTS Technology Development Team, stated, “BMTS is a concept introduced to the market for the first time by LG Energy Solution, which makes us feel an even greater sense of responsibility,” and continued, “We are continuously identifying new customer experiences and developing distinct strategies that are unique to B.around.”

Pioneering a New Path: What Sets B.around Apart and Where It’s Headed Next?

What differentiates B.around’s BMTS solutions, and what kind of future does LG Energy Solution envision? We asked the core developers to learn more.

Q. What makes LG Energy Solution’s SDV solution unique?

(Sang-Hoon Lee, Executive Director, Service Solutions)

Since SDVs are vehicles whose major functions are controlled by software, the amount of data that needs to be processed becomes much greater. In response, automakers began adopting high-performance computing (HPC). This shift completely changed the vehicle platform architecture from conventional structures to zonal architecture. Software is also continuously updated using OTA1 via wireless networks.

As a result, some or most functions previously performed by hardware or in the cloud are now transferred to HPC, and the form of BMS is also evolving. LG Energy Solution is offering battery management solutions optimized for SDVs by incorporating more advanced battery safety diagnostics and degradation/lifetime prediction software. We also offer solutions that allow users to check the battery’s condition and degradation information in real-time or control vehicle operations when the target lifespan is reached.

Another differentiating factor is that LG Energy Solution can offer a variety of SDV solutions. The high-performance chip co-developed with Qualcomm comes pre-installed with LG Energy Solution’s proprietary battery management functions, providing an onboard solution that can be used immediately without additional configuration.

We also offer options for customers who don’t use this chip. For example, our safety diagnostics and degradation/lifetime prediction software can be added to their existing chip systems. Using data collection devices (OBD) like LG Energy Solution’s B-Checkup, we collect and store data, analyze it, and provide a cloud-based environment to refine the algorithms. Based on this flexibility, we aim to meet a wide range of customer needs.

Q. How does BMTS’s safety diagnostic software compare to traditional battery diagnostic systems?

(Cheol-Taek Kim, VP, Diagnostics Department)

BMTS’s safety diagnostic software features diagnostic logic developed for the first time in the industry. Compared to conventional BMS, it can detect much subtler issues in advance and prevent them. Until recently, battery safety management mainly focused on preventing battery misuse. Even if misuse was prevented, diagnostics were only conducted when cells showed abnormalities or when clear performance issues occurred.

To improve battery safety beyond previous standards, it became critical to detect subtle signals or characteristics before any issue surfaced. To do this, we conducted various experiments, collected vast amounts of data, and analyzed it to identify anomalies, gradually refining our diagnostic algorithms. We also reviewed battery cell charger/discharger data to detect potential issues. Later, by explaining our logic and solutions to OEM customers and engaging them in collaboration, we were able to secure a large volume of vehicle operation data.

As a result, we acquired the technical capability to detect issues before they happen. This represents a shift in the safety paradigm—from reactive response to proactive prediction. The diagnostic logic developed through this process includes MAVD, RdV, and dSOH, and these achieve an industry-leading detection accuracy of over 90%.

Q. What are the strengths and unique features of LG Energy Solution’s lifetime prediction software?

(Sang-Hoon Lee, Executive Director, Service Solutions)

The degradation/lifetime prediction software is a technology designed to forecast the future condition of a battery. To put it in human terms, checking various health indicators reflects your current health, and using that data to analyze how you’ll be in three or five years is what the degradation/lifetime prediction software does.

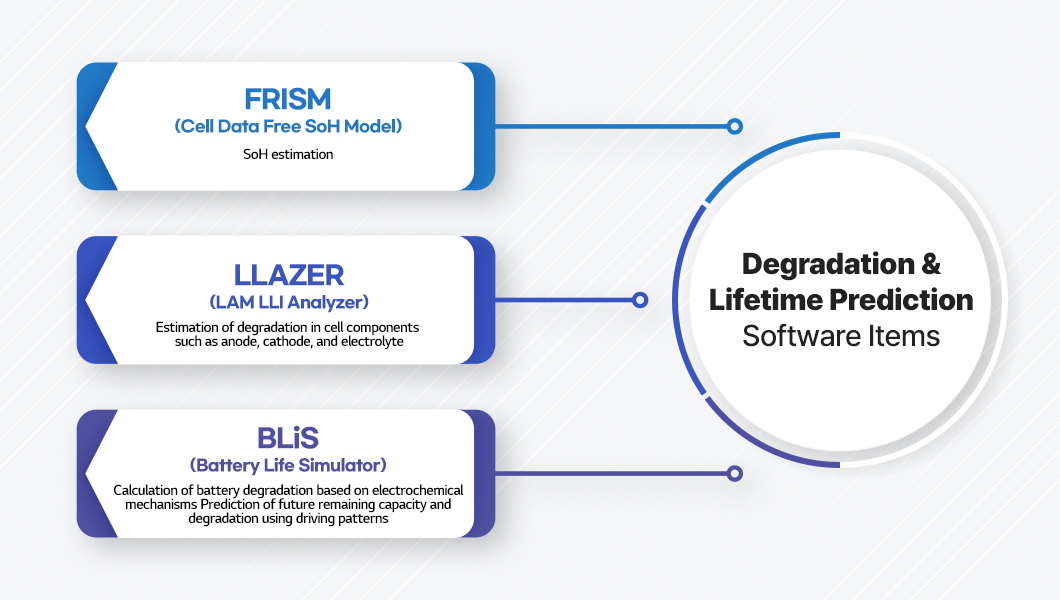

Among battery indicators, identifying the key items that help with future prediction is essential to reduce uncertainty. That’s why LG Energy Solution integrated three proprietary technologies—FRISM, LLAZER, and BLiS—into the software. These technologies assess not only the remaining battery capacity but also the degradation levels of key components like the cathode, anode, and electrolyte. They also incorporate electrochemical mechanisms and analyze users’ application patterns. Each technology focuses on different aspects of degradation and lifespan, allowing for highly precise and multi-faceted diagnosis.

As a result, LG Energy Solution’s degradation/lifetime prediction software achieves an error margin of just 1–2%, demonstrating extremely high prediction accuracy. Considering that current industry standards for degradation/lifetime prediction fall in the range of 5–7%, LG Energy Solution’s technology stands out as distinctly superior.

Q. What roadmap is in place to strengthen the competitiveness of BMTS technology?

(Dong-Geun Kwon, Team Leader, BMTS Technology Development Team)

Our BMS Development Group is constantly considering how to deliver greater value to customers through technology, and we continue striving for new innovations. For example, we are working to develop future technologies using methods such as EIS (Electrochemical Impedance Spectroscopy), and we are strengthening our hardware differentiation through collaboration with chip manufacturers like Qualcomm and ADI.

On the software side, we are expanding our business areas. While we currently work with OEMs, we plan to extend BMTS applications to BaaS and EaaS as well. Furthermore, we are exploring ways to apply BMTS software in the energy trading market. In line with the growing EV market, we are also focusing on developing technologies that can simplify regular EV maintenance inspections.

(Sang-Hoon Lee, Executive Director, Service Solutions)

We plan to further improve the performance of the degradation/lifetime prediction algorithms by reducing even the current 1–2% error rate. At the same time, we aim to broaden their applicability across various sectors. Batteries vary depending on the cathode materials used—such as NCM, NCA, and LFP—and also come in various form factors, including cylindrical, prismatic, and pouch types. Therefore, designing and tuning algorithms that match the characteristics of each battery type is crucial. Our core challenge is to continuously enhance the universality of the software so it can be applied to a wider range of batteries.

We are also working to make the degradation/lifetime prediction software lighter. Since BMTS is a solution that combines AI and cloud technologies to process and analyze large-scale data, optimization for speed and efficiency is essential. In addition, we plan to further enhance security to protect data and ensure system stability.

(Cheol-Taek Kim, Vice President of the Diagnostics Department)

We will continue to reinforce our safety diagnostic software to detect even the smallest signs of defect, minimize risk, and ensure safety. Since 2018, LG Energy Solution has been classifying defect types and risk levels and analyzing their characteristics. We plan to further enhance the software by improving defect detection rates and accuracy.

Q. What is LG Energy Solution’s ultimate vision through BMTS?

(Sang-Hoon Lee, Executive Director, Service Solutions)

Batteries are now used in various applications in everyday life—electric vehicles, e-bikes, robots, ESS, and more. As we approach the era of BoT (Battery of Things), we believe that a solution to improve battery efficiency and manage the entire battery lifecycle will become essential.

Through B.around, LG Energy Solution aims to make a new impact—and ultimately, we hope that our technology will become the standard for battery management.

(Cheol-Taek Kim, VP of the Diagnostics Department)

Through BMTS, we envision a safe and sustainable future for batteries. Even after about 10 years of use, batteries often retain around 90% of their capacity, and many can still be reused even at 80% or 70%. BMTS’s precise diagnostic and prediction technologies will not only unlock new value in such batteries but also help determine whether they pose any safety concerns.

(Dong-Geun Kwon, Team Leader, BMTS Technology Development Team)

Just like LG Energy Solution’s vision, “Empower Every Possibility,” or Awaken the World with Energy, we hope B.around will be present wherever energy is needed—in technology, in people, in nature. As trust in B.around continues to grow, we believe our customer base will expand naturally.

Through Parts 1 and 2 of this interview, we’ve explored LG Energy Solution’s BMTS and its brand, B.around. With this groundbreaking innovation, LG Energy Solution aims to deliver new economic and environmental value, and fundamentally transform our future daily lives. Stay tuned as LG Energy Solution continues to open new possibilities in battery management!

- OTA: Over-the-air technology that updates software wirelessly ↩︎