LG Energy Solution is enhancing customer value by establishing production facilities worldwide! Today’s World Battery Tour heads to the United States, where LG Energy Solution has partnered with automaker General Motors (GM). Which state in the U.S. captured the attention of the sharp-witted LG Energy Solution?

Tennessee, Where Nature and Country Music Thrive

The state of Tennessee, located in the southeastern part of the U.S., is nestled in the Appalachian Mountains that stretch from the northeastern to the southwestern parts of North America. It is bordered by eight states: Kentucky and Virginia to the north; North Carolina to the east; Georgia, Alabama, and Mississippi to the south; and Arkansas and Missouri to the west. Additionally, it is adjacent to the Mississippi River, the largest river in the U.S., which runs from north to south through the central part of the country.

Tennessee is also known for its history of music. The state capital, Nashville, is considered the origin of traditional American country music. Many country music hits have been recorded here, and the iconic Grand Ole Opry radio show on Nashville’s WSM station continues to uphold the legacy of country music.

This state is home to the Great Smoky Mountains National Park, the most visited national park in the U.S. Designated a UNESCO World Heritage site in 1983, it is renowned for its vast wilderness and diverse wildlife.

Last but not least, Tennessee is a transportation hub. Its strategic location along the Mississippi River has attracted many manufacturing companies to establish operations in the state.

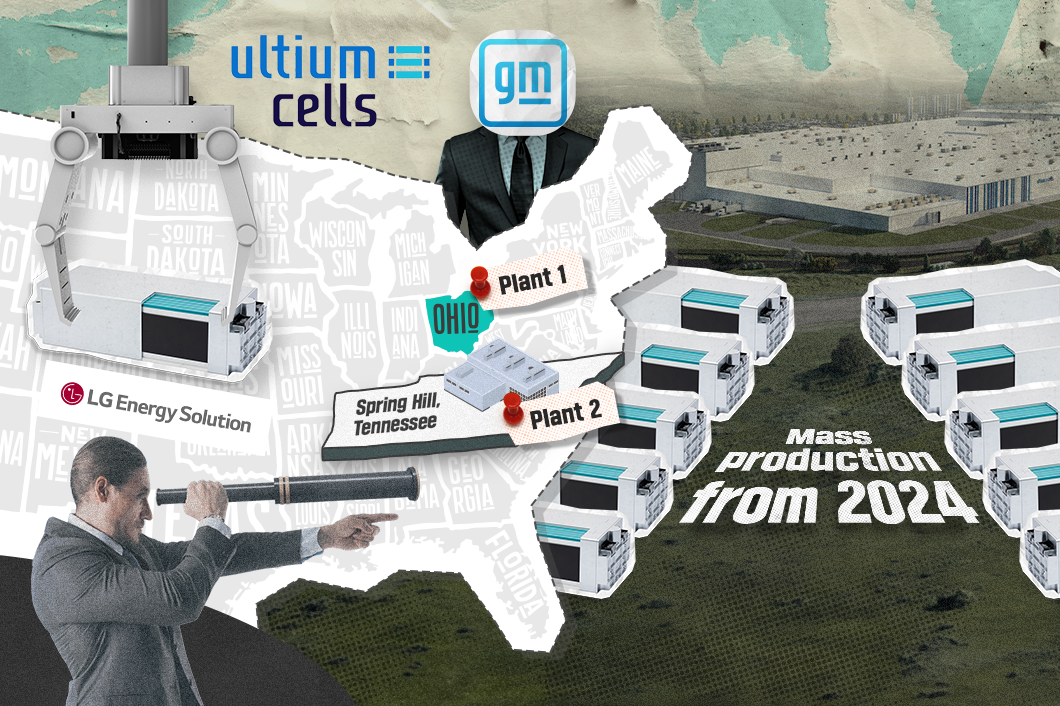

Ultium Cells, the Joint Venture of LG Energy Solution, Built the Second Plant in Tennessee

LG Energy Solution had recognized these geographical advantages and established a battery production plant in Tennessee. In 2022, LG Energy Solution, in collaboration with automotive company GM, constructed the second plant of Ultium Cells in Spring Hill, Tennessee.

The Ultium Cells’ second plant has advanced smart factory systems that help maximize production efficiency. These cutting-edge systems integrate automation, information technology, and intelligence to streamline operations. The automated manufacturing process and facilities have significantly increased production speed. Furthermore, advanced quality inspection and error verification methods adopted for each production stage ensure the production of high-quality batteries.

Equipped with such infrastructure, the second plant successfully commenced battery production in 2023 and began a full-scale mass production in the following year. In April 2024, the first battery cells were delivered to customers. The batteries produced at this facility are set to be installed in GM’s third-generation electric vehicle models.

The second plant aims at gradually increasing its production lines. The plan is to expand its production capacity to support manufacturing of approximately 600,000 high-performance electric vehicles with a range of over 500 km on a single charge. Its goal for the production capacity is to reach 50 GWh in total.

On this World Battery Tour, we explored LG Energy Solution’s activities and collaboration with the global enterprise in Tennessee, a region with excellent locational advantages. LG Energy Solution plans to continuously target the North American market with its global competitiveness. In the next session, we will travel to Arizona, U.S., to examine LG Energy Solution’s strategies there.