The leading player in the current battery market is undoubtedly the lithium-ion battery. Since its commercialization in 1991, lithium-ion batteries have been widely used for a variety of applications, including electric vehicles and IT devices. However, as diverse battery needs emerged, people came to want batteries whose performance surpass that of lithium-ion batteries. Hence the battery industry’s continuous research to develop successors to lithium-ion batteries.

In the Game Changer Battery series, we will introduce the batteries that are expected to revolutionize the future battery market. In this session, we will look in-depth at the lithium-sulfur battery, one of the most promising next-generation batteries.

What Is a Lithium-Sulfur Battery?

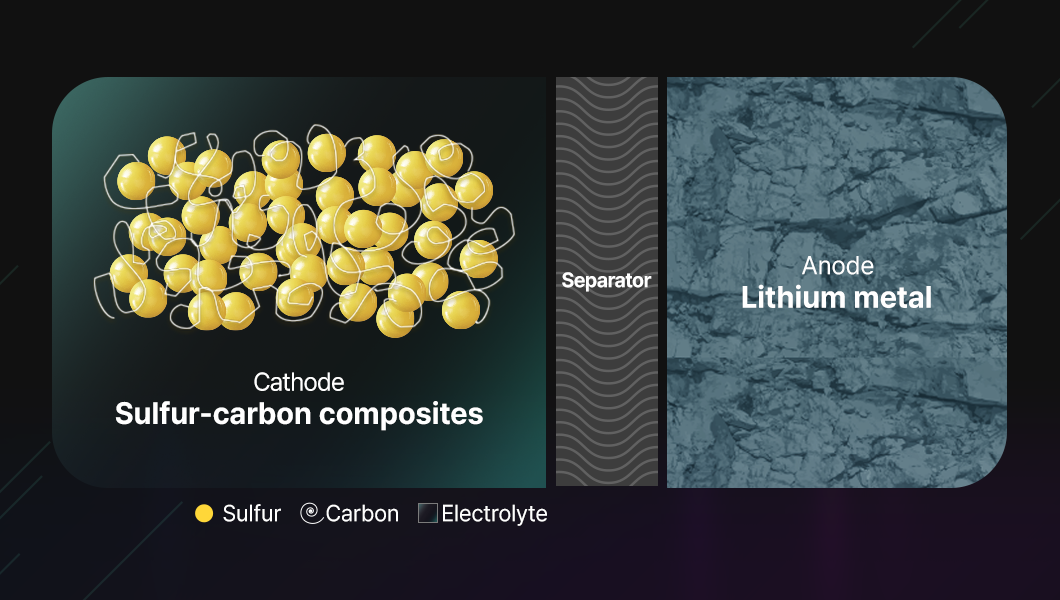

A lithium-ion battery utilizes metal oxides (such as LCO, NMC, NCA, and LFP) for the cathode and graphite and silicon for the anode. And a lithium-sulfur (Li-S) battery uses a sulfur-carbon composite for the cathode and lightweight lithium metal for the anode.

In fact, the development of lithium-sulfur batteries predates that of lithium-ion batteries. In 1962, American scientists Herbert Danuta and Ulam Juliusz patented the first primary cell that had sulfur for the cathode and lithium for the anode. This marked the emergence of lithium-sulfur batteries. The subsequent introduction of lithium nitrate (LiNO3) enabled this battery to function as secondary (rechargeable) cells.

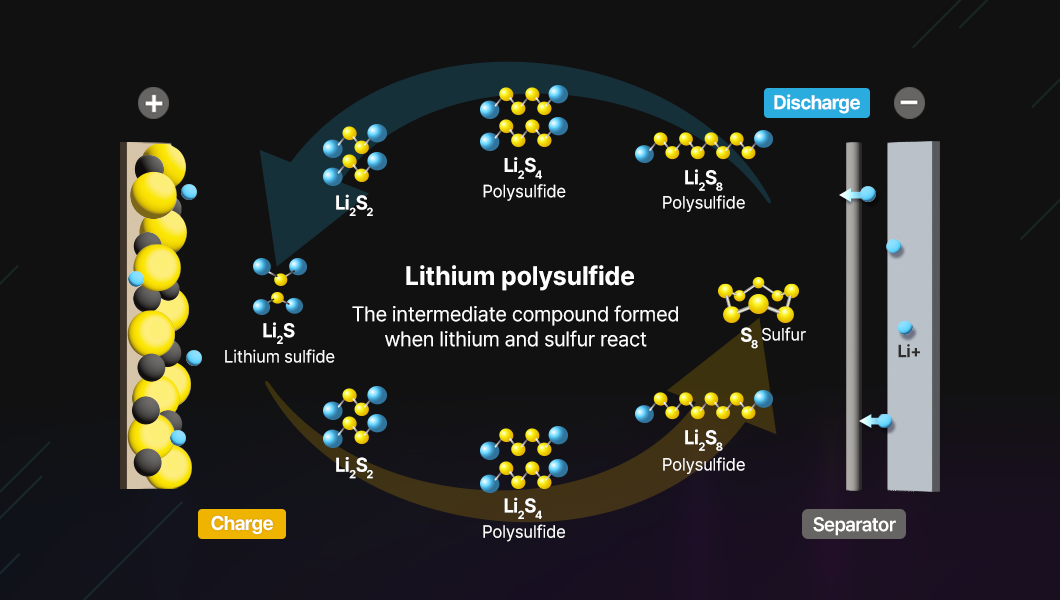

While lithium-ion batteries generate electrical energy through the redox reactions of electrons separated from lithium ions, lithium-sulfur batteries produce electrical energy through the stepwise conversion of sulfur.

As for the structure, sulfur is composed of rings of eight atoms (S8). During the discharge process of lithium-sulfur batteries, sulfur (S8) molecules undergo a series of successive reduction reactions and transform into linear-structured lithium polysulfide, an intermediate compound formed when lithium and sulfur react. As the reduction reactions continue, the polysulfide ultimately turns into lithium sulfide (Li₂S), an insoluble substance, which generates electrical energy in the process.

Characteristics of Lithium-Sulfur Batteries, a Cornerstone of Next-Generation Batteries

Lithium-sulfur batteries possess distinct characteristics that differentiate them from lithium-ion batteries. One of the features is their high gravimetric energy density. The sulfur-carbon composite used for the cathode and the lithium metal used for the anode have low densities, resulting in a high capacity per unit weight. Consequently, the gravimetric energy density of lithium-sulfur batteries is more than 1.5 times higher than that of lithium-ion batteries.

*Gravimetric Energy Density (Wh/kg): Energy stored in the battery (Wh) / Weight of the battery (kg)

To put it simply, lithium-sulfur batteries are lightweight. While lithium-ion batteries use metallic elements like nickel and cobalt for the cathode, lithium-sulfur batteries utilize lighter materials such as sulfur and lithium, reducing their overall weight. The weight of a battery is a crucial factor because it determines how much capacity can be generated per gram of active materials.

The sulfur used for the cathode of lithium-sulfur batteries can achieve a capacity of 1,675 mAh/g, whereas the NCM (nickel-cobalt-manganese) in lithium-ion batteries typically makes about 200 mAh/g. This means that lithium-sulfur batteries are approximately eight times lighter than lithium-ion batteries. Additionally, the lithium anode in lithium-sulfur batteries has a capacity of 3,500 mAh/g, compared to the 350 mAh/g the graphite anode produces in lithium-ion batteries.

Furthermore, sulfur is the 17th most abundant element on Earth, making it relatively easy to obtain and accordingly, very inexpensive. Therefore, replacing lithium with sulfur for the cathode would provide a significant cost advantage.

Lithium-sulfur batteries are gaining significant attention in the aviation sector, especially for use in drones, unmanned aerial vehicles (UAVs), and Urban Air Mobility (UAM) systems. A lightweight design is crucial for aerospace equipment, and the light weight of lithium-sulfur batteries can improve fuel efficiency. Additionally, with their high energy density relative to weight, these batteries are expected to enable longer flight times and greater distances compared to lithium-ion batteries.

LG Energy Solution Secures Future Technological Competitiveness with Pouch-Type Lithium-Sulfur Batteries

LG Energy Solution first noticed the importance of lithium-sulfur batteries in 2013 in its “innovative battery” project. At that time, various next-generation batteries were considered, and foundational experiments were conducted to identify the most suitable technology for showcasing LG Energy Solution’s technical capabilities. After thorough research and experimentation, lithium-sulfur batteries and lithium-metal batteries were finally selected as the subjects of our key R&D projects in 2015. Currently, lithium-sulfur battery research continues as one of the next-generation battery initiatives at the LG Energy Solution Future Technology Center.

One notable aspect of LG Energy Solution’s lithium-sulfur battery development is the choice to manufacture these batteries in a pouch format. Why did we opt for the pouch type among various forms?

First, to further reduce the weight of lithium-sulfur batteries. A lithium-sulfur battery uses lighter materials compared to a lithium-ion battery of the same capacity and energy. However, encasing the materials in metal cans with cylindrical or prismatic shapes may undermine the advantage of being lightweight. Therefore, LG Energy Solution chose the pouch type to maximize the inherent lightness of lithium-sulfur batteries.

Second, the pouch type can better accommodate the volumetric changes of lithium-sulfur batteries. The lithium metal used for the anode of lithium-sulfur batteries can change in thickness during charge and discharge cycles. The flexible exterior of a pouch-type battery can effectively manage these changes in thickness, making it a suitable choice for maintaining the structural integrity of the battery.

LG Energy Solution’s Lithium-Sulfur Battery Roadmap

However, several challenges must be addressed for lithium-sulfur batteries to become established in the market. They include the low electrical conductivity of sulfur, the elution of lithium polysulfides, and the volumetric changes during charge and discharge cycles. LG Energy Solution is making significant efforts to overcome these obstacles.

LG Energy Solution decided to increase the conductivity of sulfur. So, we developed carbon materials with structures and properties designed to use sulfur more effectively and created cathode electrodes with them. Since sulfur is an insulator with high resistance, it requires conductive additives like carbon to facilitate electron transfer. Lithium-sulfur batteries need particularly more conductive additives, and the characteristics of these additives impact the performance considerably. LG Energy Solution has built a system that allows use of a larger quantity of sulfur more efficiently.

To tackle the issue of lithium polysulfide elution, LG Energy Solution has developed a new combination of electrolytes. The elution problem is caused by organic solvents and lithium salts used for the electrolyte. Continuous research on these materials has led to significant improvements. Currently, LG Energy Solution’s electrolyte for lithium-sulfur batteries effectively controls lithium polysulfide elution, dramatically enhancing the battery’s lifespan.

Lastly, LG Energy Solution has not only adopted the pouch format but has also secured pressure control technology to address the volumetric changes during the charge and discharge cycles of lithium-sulfur batteries. Volumetric change is commonly observed in batteries using lithium metal for the anode, and maintaining the shape requires processes that utilize appropriate pressure. LG Energy Solution has controlled volumetric changes in lithium-sulfur batteries most effectively with our know-how accumulated for years, thereby extending their lifespan.

LG Energy Solution is presently aiming to commercialize lithium-sulfur batteries by 2027. The ultimate goal is to make lithium-sulfur batteries lighter and last longer than lithium-ion batteries so that customers will prefer them. This will be achieved through continuous research and overcoming existing challenges.

We have explored the features of the lithium-sulfur battery, LG Energy Solution’s anticipated game changer in the future battery market. Although many obstacles are ahead for us to commercialize it, the advantages of lighter weight and higher gravimetric energy density makes a lithium-sulfur battery a promising next-generation technology. Stay tuned to find out which battery technology will be introduced next!