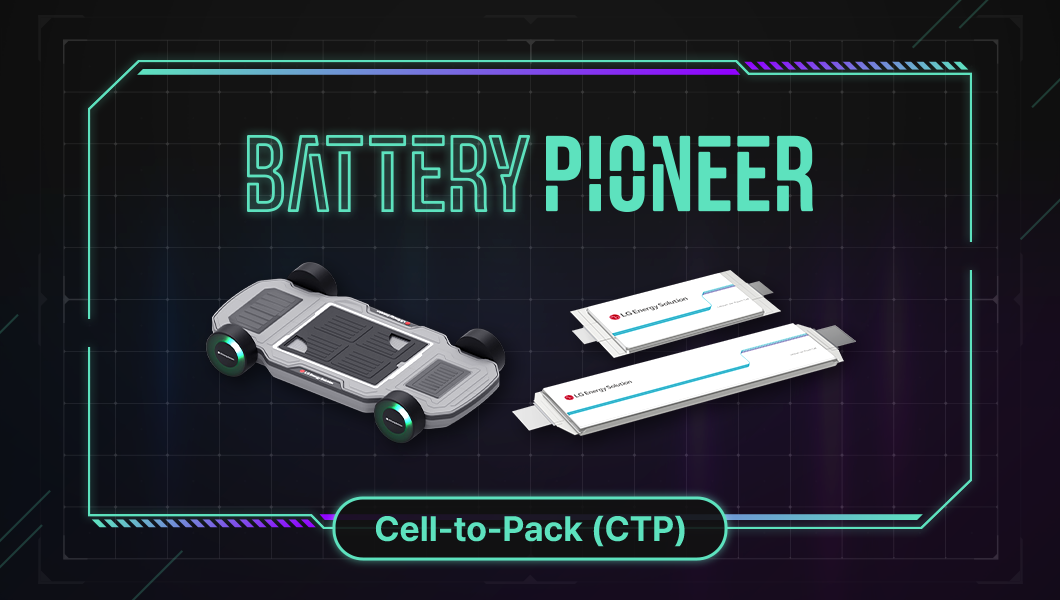

From March 6 to 8, 2024, LG Energy Solution’s groundbreaking Cell-to-Pack (CTP) technology was showcased at InterBattery 2024, a prominent secondary battery industry exhibition. This innovative technology assembles cells directly into the battery pack, bypassing the need for modules. LG Energy Solution garnered significant attention as the first in the industry to apply CTP technology to pouch-type batteries. Let’s delve into what CTP technology entails and what distinguishes LG Energy Solution’s CTP from others.

Cell-to-Pack (CTP) Enhances Energy Density through Space Utilization

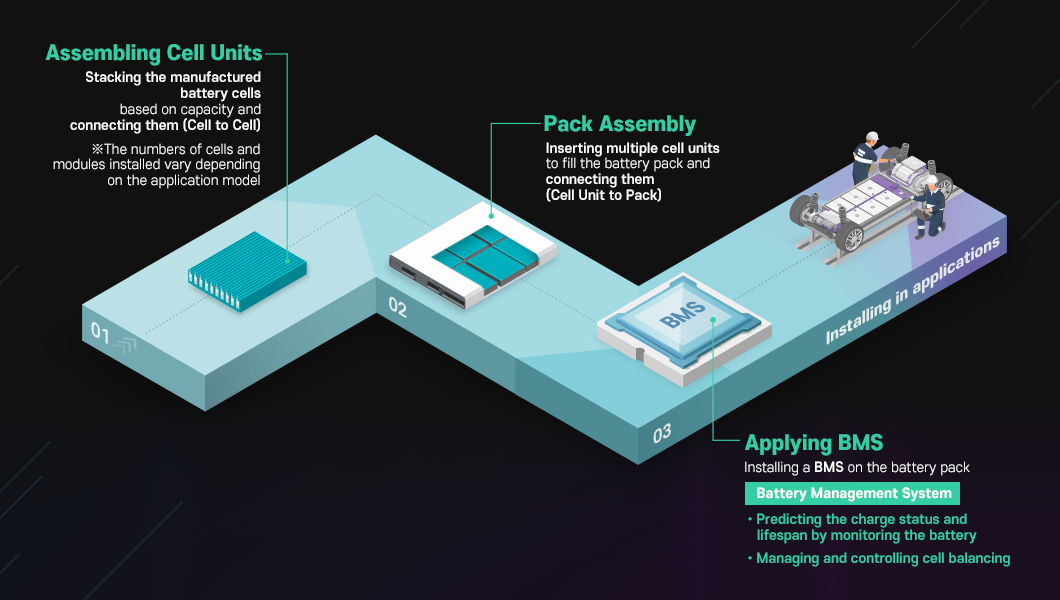

Typically, the operating voltage of a battery cell ranges from 2.5V to 4.5V. For this reason, multiple battery cells must be modularized and connected in series or parallel to form a battery pack to be mounted on applications such as electric vehicles (EVs) or energy storage systems (ESS) that require a high-capacity and high-output battery. The performance and energy capacity of the battery pack are directly determined by the number and configuration of its cells and modules. Therefore, technology to efficiently configure as many cells and modules as possible in a battery pack is crucial for developing a high-performance battery.

Cell-to-Pack (CTP) technology has emerged as a solution to these challenges. CTP allows battery cells to be directly integrated into packs without modularization. Using CTP, even the space previously occupied by module cases themselves can be filled with cells. In other words, by minimizing dead space inside the pack, additional space can be secured, increasing energy density and capacity. Additionally, as the module process is eliminated, the number of components used is reduced compared to the existing process, leading to reduced pack manufacturing time and cost savings. Meanwhile, since CTP batteries do not contain a module to secure and protect the cells, it is important to ensure safety through methods such as shock absorption, which is being researched as a major task along with CTP process optimization and thermal protection (TP) solutions.

LG Energy Solution, an Industry First to Apply CTP to Pouch-Type Batteries

LG Energy Solution has been at the forefront of developing cutting-edge technologies in response to the growing demand for high-performance batteries, including Cell-to-Pack (CTP) technology. Demonstrating interest in CTP from early on, LG Energy Solution has come a long way from developing Module Pack Integrated (MPI) technology, which integrates modules and packs, to CTP through continuous research and development.

A particularly noteworthy progress LG Energy Solution has made is its application of CTP technology to pouch-type batteries as the first in the battery industry, garnering considerable attention. Pouch-type battery cells are lightweight and have minimal dead space when stacked. By leveraging these advantages, LG Energy Solution developed a pouch-type CTP battery that maximizes battery capacity and output with exceptional space efficiency.

The Structure of LG Energy Solution’s CTP-Applied Pouch-Type Battery Cell

What manufacturing process does LG Energy Solution’s CTP-applied pouch-type battery go through? First, more than two pouch-type battery cells, either separated or stacked, are arranged, and compression pads are attached to the sides. These battery cells are then electrically connected through busbars and covered with a cell cover to form a single cell unit. The cell cover protects the pouch-type battery cells from external shocks and maintains the stability of the stacked arrangement.

Once the cell units are assembled, thermal resin is applied to the pack case, and the cell units are placed inside. The thermal resin enhances heat transfer between the pack case and the base plate, increasing the cooling efficiency of the battery cells. Finally, a Battery Management System (BMS) is installed to monitor and control various parameters of the battery.

LG Energy Solution aims to mass-produce pouch-type batteries equipped with CTP technology by 2025. It plans to significantly streamline the manufacturing processes compared to the Module-to-Pack (MTP) process by innovating the CTP process. The pouch-type CTP developed by LG Energy Solution is designed to have approximately 5% higher energy density per weight compared to prismatic CTP, which can provide a solution to enhance vehicle efficiency based on the client’s needs. Additionally, a CTP pilot line has been established with the goal of developing and verifying new methods for more advanced CTP implementation. Currently, the CTP pilot line is focused on discovering and researching tasks for CTP process innovation in various areas such as assembly, welding, application, and inspection.

In this episode, we have explored CTP technology in more detail. LG Energy Solution is continuously striving to secure higher battery pack performance by adopting CTP technology for pouch-type batteries. Stay tuned and keep an eye out for LG Energy Solution’s efforts to bring innovation to the battery market with differentiated technology!