We tackle all the questions about batteries and LG Energy Solution, through our ‘Ask LG Energy Solution Anything’ sessions! This time, we will take a look at how LG Energy Solution is managing its supply chain.

LG Energy Solution has established supply chain management policies, strategies, and management systems based on the standards and frameworks required by the OECD (Organization for Economic Co-operation and Development), UN (United Nations), and ILO (International Labour Organization). This is to minimize risks related to the supply chain in human rights and labor, ethical management, workplace safety and health, environmental sustainability, and responsible mineral sourcing.

Based on this strategy, LG Solution is making efforts to manage the entire battery supply chain to build a sustainable battery ecosystem. In particular, we are trying to expand our supply chain by promoting ESG activities with our Tier 1 partners with whom we have direct business relationships. To this end, we have a code of conduct in place for partner companies, which consists of regulations and principles that they must comply with to operate a sustainable supply chain, related to human rights and labor, ethical management, workplace safety and health, environmental sustainability, responsible mineral sourcing, and grievance handling systems. In addition, we are securing continuity in management through ESG evaluation of partner companies and gradually expanding due diligence on the supply chain of major raw materials to secure supply chain traceability.

Moreover, LG Energy Solution is building its own supply chain of critical raw materials and strengthening a stable supply chain by preemptively securing raw materials such as lithium, nickel, manganese, cobalt, sulfur, and aluminum used in battery production.

In addition, LG Solution is building a solid supply chain network in cooperation with global companies. We will source 25% of total spodumene concentrate production from Australian company Green Technology Metals for five years from 2026 and 2,000 tons of natural graphite from Australian company Syrah for five years from 2025. Lastly, we signed a supply contract with QPM, an Australian battery mineral smelting company, to secure 7,000 tons of nickel and 700 tons of cobalt for 10 years from 2025.

In North America, we have built a critical mineral supply chain with Canadian mineral companies Electra and Snow Lake Lithium as well as US lithium producer Compass Minerals. We will receive a supply of 7,000 tons of cobalt sulfate from Electra over three years from 2023 and 200,000 tons of lithium hydroxide from Snow Lake Lithium over 10 years from 2025. Through Compass Minerals, we will source 40% of the lithium carbonate and lithium hydroxide it produces for 7 years from 2025.

In Europe, 45,000 tons of lithium hydroxide will be supplied through German lithium producer Vulcan Energy over a five-year period starting in 2026. In addition, we have established a supply chain at many sites around the world through collaboration with companies in various countries such as China, Indonesia, and Chile.

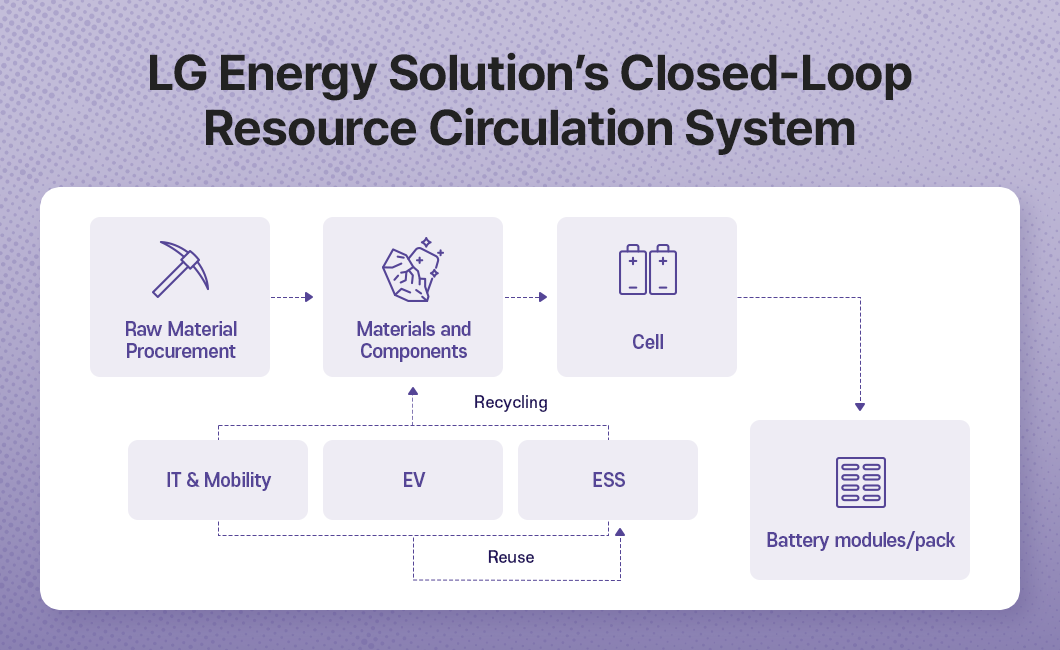

Lastly, LG Energy Solutions is properly managing its supply chain by reusing and recycling used batteries. To this end, we are establishing a virtuous resource cycle system that encompasses the entire product value chain, from production of raw materials to consumption and disposal.

What questions are waiting for our next issue of ‘Ask LG Energy Solution Anything’? Please look forward to our answers to any questions you have about batteries and LG Energy Solution!