There is ongoing innovation in battery manufacturing technology with the progress in industries such as electronics and EVs. Governments and battery manufacturing companies around the world are striving to develop next-generation batteries capable of replacing lithium-ion batteries. So, what are considered to be next-generation batteries?

Q. What are considered to be next-generation batteries?

The next-generation batteries have not been commercialized yet, but they represent the batteries that will be used in the future. Lithium-ion batteries are currently dominant in the battery market. The next-generation batteries can be alternatives to replacing a significant portion or the majority of these lithium-ion batteries.

Next-generation batteries are required to have high energy density, output, safety, and price competitiveness. Among those that meet the requirements are solid-state batteries and lithium-sulfur batteries.

Q. What are the features of solid-state batteries?

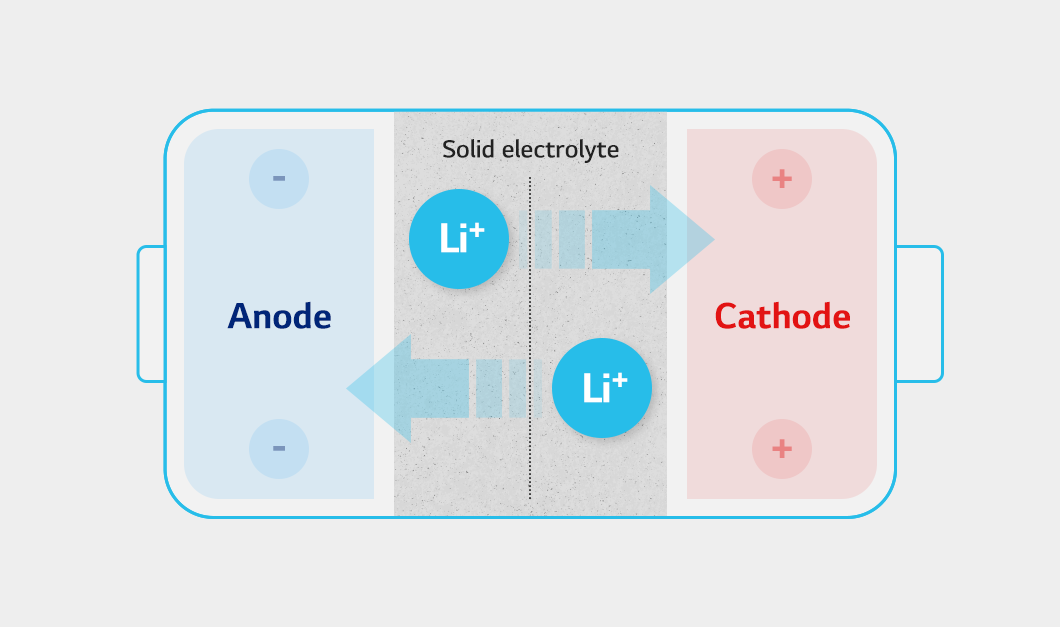

Among the components of a lithium-ion battery, the “electrolyte,” which facilitates the movement of lithium ions, possesses liquid properties. A separator is placed between the electrolyte to prevent direct contact between the cathode and anode.

A solid-state battery is a battery with a solid electrolyte. Since a solid electrolyte has a hard structure, it itself can work as a separator that keeps the cathode and anode apart. This feature reduces the risk of explosions generated by the direct contact between the cathode and the anode and enhances stability by maintaining its form even if the electrolyte is damaged by external impacts.

Furthermore, as no separator is required, more active materials can be filled into that space.

This feature improves battery safety and energy density per volume, making solid-state batteries the right candidate for high-capacity EV batteries. Not only that, due to its versatility based on battery usage, research and development on solid-state batteries are rapidly progressing.

Q. What are the features of lithium-sulfur batteries?

A lithium-sulfur battery is a battery that employs sulfur as a cathode material and lithium metal as an anode material. The expensive cobalt is primarily used as the cathode material in the current commercialized lithium-ion batteries. Lithium-sulfur batteries can substitute cobalt with the abundant and cost-effective material ‘sulfur’ for cathodes. Additionally, instead of using graphite for the anode material, lithium metal is employed.

Since these materials have low density and high capacity per weight, they increase in energy density to over two times (>500Wh/kg) and lightweight battery. Furthermore, it is environmentally friendly as it does not require the use of rare metal materials such as cobalt and nickel. Likewise, lithium-sulfur batteries representing next-generation batteries not only have cost competitiveness but also can realize environmentally friendly high-capacity batteries.

Due to these characteristics, lithium-sulfur batteries are gaining attention as a power source for future transportation methods such as drones and aircraft. In 2020, LG Energy Solution and the Korea Aerospace Research Institute developed a high-altitude long-endurance solar-powered unmanned vehicle equipped with lithium-sulfur batteries and they succeeded in flight testing of the vehicle at the highest altitude for 13 hours, which garnered significant attention from the public. The plans to commercialize lithium-sulfur batteries from 2025 are also raising high expectations.

Q. What is LG Energy Solution doing to develop future-generation batteries?

LG Energy Solution revealed our ambition to drive the development of next-generation battery technology and new businesses to achieve a sustainable future. We are currently conducting battery research in cooperation with prestigious global universities.

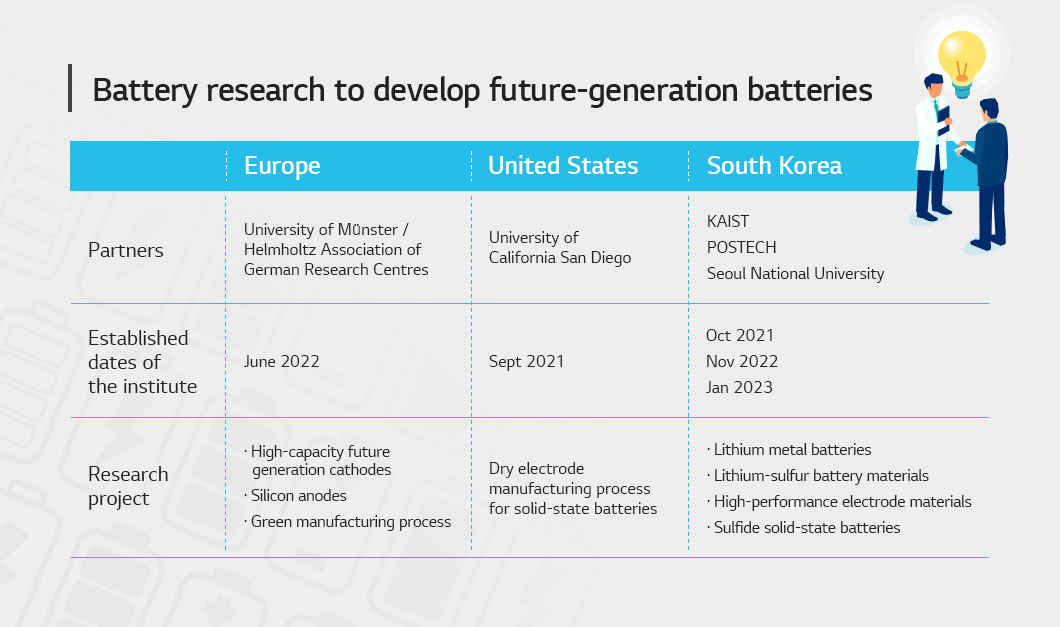

LG Energy Solution established the Frontier Research Laboratory in collaboration with our global partners: the University of California San Diego, Münster Electrochemical Energy Technology (MEET) of the University of Münster and Helmholtz Institute Münster (HI MS) of Forschungszentrum Jülich. We developed an all-solid-state battery technology capable of high-speed charging at room temperature in the UCSD FRL. Meanwhile, the MEET FRL will focus on next-generation cathode material technology, silicon anode technology, and an eco-friendly production process.

Furthermore, prestigious domestic universities such as KAIST, POSTECH (Pohang University of Science & Technology), and Seoul National University are also conducting research on next-generation batteries. At KAIST, research on solid-state batteries, dry electrode manufacturing, lithium metal, and lithium-sulfur battery technologies is ongoing. In January of 2023, they achieved a breakthrough in developing lithium-sulfur batteries with improved energy density and lifespan compared to conventional ones.

POSTECH (Pohang University of Science & Technology) is currently involved in the development of fast-charging and long-lasting battery materials, high-performance electrode materials, manufacturing technologies, and more. They are concentrating their efforts on a total of 11 industry-academic collaboration projects. Lastly, a total of 9 industry-academic collaboration projects will be carried out with Seoul National University to develop sulfide-based solid-state batteries and materials for lithium-sulfur batteries.

We have delved into solid-state batteries and lithium-sulfur batteries, both of which are garnering attention as next-generation batteries. Please maintain a keen interest in how these next-generation batteries will shape our future sustainably!